Food Packing Machinary for Hard Candy Packing Machine CB-320

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Food Packing Machinary for Hard Candy Packing Machine CB-320

1. Structure of Food Packing Machinary for Hard Candy Packing Machine CB-320 Description

Packaging various kinds of regular objects like biscuit, pies, chocolate, bread, instant noodles, moon cakes, drug .

Suitable for regular products like moon cake, biscuit, bread, candy, medicine, daily article, hardware, carton, tray etc.

2. Main Features of the Food Packing Machinary for Hard Candy Packing Machine CB-320

Driven Type: Electric

Automatic Grade: Automatic

Packaging Type: Bags

After-sales Service Provided: Engineers available to service machinery overseas

Fast Delivery time only need 7-10 working days

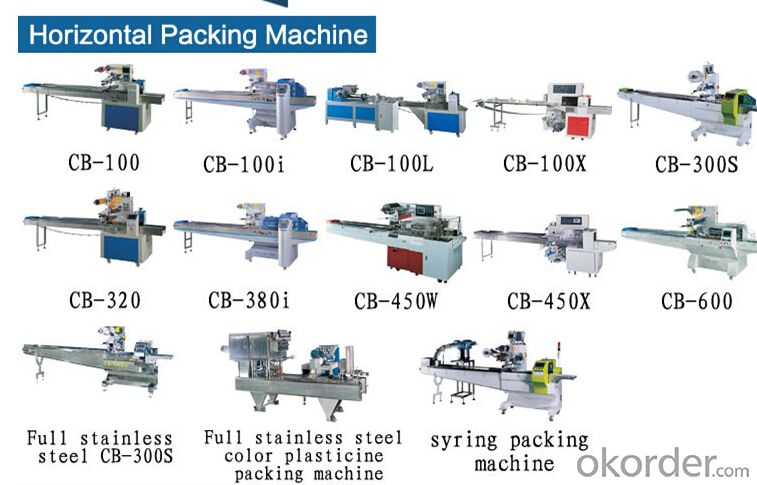

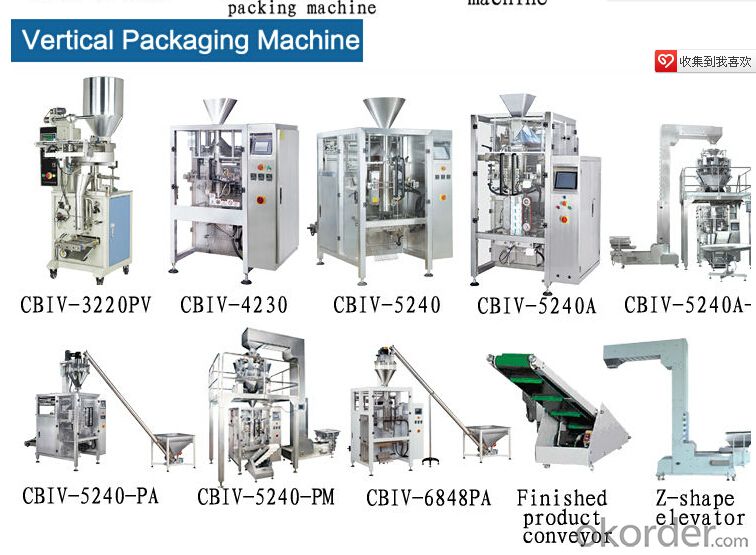

3. Food Packing Machinary for Hard Candy Packing Machine CB-320 Images

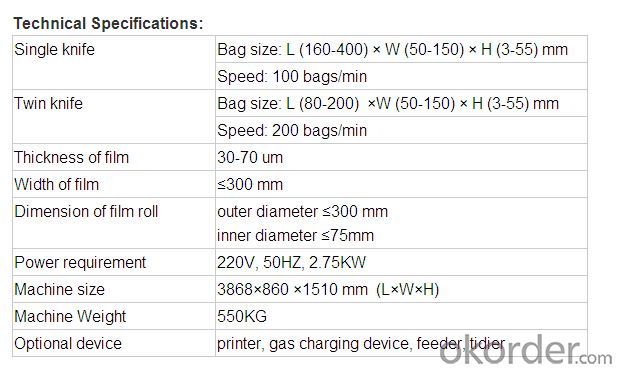

4. Food Packing Machinary for Hard Candy Packing Machine CB-320 Specification

5. FAQ of Food Packing Machinary for Hard Candy Packing Machine CB-320

A. Can you tell us what is the Function Description?

The key parts of the machine are adopted of stainless structure, in accordance with food QS and medicine GMP health requirements.

High sensitive electronic eye tracing system, after setting, the machine is no need to be adjusted by hand, the cutting position is accuracy, and the seal is firm and beautiful.

Temperature is controlled by PID intelligence independently and steadily which is suitable for various materials.

Color touch-screen display, machine can be turned off by position; fault is self-diagnosed and displayed clearly.

Counting automatically, the packaging production’s counting is accuracy.

Machine design and convey system is simple. The machine is convenient to maintain.

The machine can be equipped with gas charging device and production date code system according to client’s packaging requirements.

B. What is the exact Power?

Power: 2.75KW

- Q:Donkey hide gelatin cake made of sticky, forming very well, that is, vacuum packaging, after a little sticky in the vacuum bag, what's going on?

- For custom vacuum bags, I would recommend a manufacturer who has customized experience in vacuum bags because it reduces your time cost and offers a lot of advice on packaging design and customization.

- Q:How does the pulp solidify? What additives do you need? Curing agents? Or what do you need as binders?

- Urea formaldehyde resin is a water-soluble resin, easily cured, the cured resin colorless, non-toxic, good light resistance, long-term use does not change color, heat molding will not change color, can add various colorants to prepare various brightly colored products.Urea formaldehyde resin is hard, scratch resistant, weak acid, weak base and grease. It is cheap and has certain toughness, but it is easy to absorb water, so it has poor water resistance and electrical properties, and its heat resistance is not highThe use of urea formaldehyde resin is widely used in plastic, mold, laminated plastic, foam, also can be used for the production of water-soluble adhesive, the adhesive for wood; fabric shrinkproof and crepe treatment agent; used as a varnish of paper, in order to improve the wet strength of paper. The following is a simple Shaoxing on it the application of the plastic.

- Q:What are the packing machines?

- Heat shrink packaging machine, mask packaging machine, pillow type packaging machine, food packaging machine, I suggest you can go to see

- Q:What kind of reducer is commonly used in packaging machinery?

- Generally speaking, gear reducer, planetary gear reducer, and the most common one, these equipment power is relatively small, and some need to take the brakes of the motor reducer

- Q:Whether you can press paper plastic molding after PET

- Sure;Note cards must be coated with plastic oil;Can use blister sealing machine or high frequency plastic welding machine hot pressing;

- Q:Predecessors please point out: what is the future of packaging machinery industry?

- China's packaging machinery and equipment manufacturing enterprises should seize this opportunity.The overall upgrading of packaging machinery equipment is the general trend of the development of packaging machinery in China and the world. The main features of the renewal is: a large number of transplanted with civilian and military industries all modern high precision technology and electronic technology, microelectronic technology, edge technology, fuzzy technology, accelerate the further improve the reliability, safety, no work of the level of automation of packaging machinery and equipment and production line. Intelligence will move into the field of packaging machinery, equipment and production lines.

- Q:The difference between wrapping and bagging is explained from the packaging method, and the difference of the working principle of the packaging machine is analyzed

- Wrapping of objects of different shapes according to their appearance.

- Q:Food packaging process is not standardized, there is no responsibility?! For example, after the production of candy, because there is no corresponding packaging equipment, the need for artificial packaging

- Yes, automatic packing machine. I'm an employee of the automatic packaging machinery company.

- Q:Vacuum packing machine for cooked food: can whole chicken, whole goose and whole duck be packed?

- Well, yesBut the vacuum packaging machines used for different product sizes are different

- Q:Energy saving reform of packaging machine

- Due to the adoption of variable frequency speed regulation, the chain drive is greatly reduced, the stability and reliability of the operation of the machine are improved, and the noise of the machine operation is reduced. It guarantees the high efficiency, low loss and automatic detection of the packaging machine. It has both a beautiful and fashionable appearance, and a healthy and smart mind.Although the transmission system used in food packaging machine is relatively simple, it has higher requirements for the dynamic performance of the transmission. The system requires fast dynamic follow-up performance and high stability speed accuracy. Therefore, we must consider the dynamic technical indicators of inverters, and select high-performance inverter to meet the requirements.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Food Packing Machinary for Hard Candy Packing Machine CB-320

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords