Food Industry White Food Grade PVC PU Conveyor Belting

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Food Industry White Food Grade PVC PU Conveyor Belting

Conveyor Belt Description:

Light Duty Conveyor Belts for food industry are excellent resistant to oil and fat, non-toxic, healthy and easy to clean. The type of belts conforms with FDA, USDA and EU regulations, can be used in many applications in the following industries: bakery, confectionary, meat and poultry, fish, fruit and vegetables, dairy, agriculture etc.

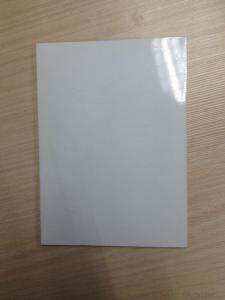

Color: black, white, green, blue etc.

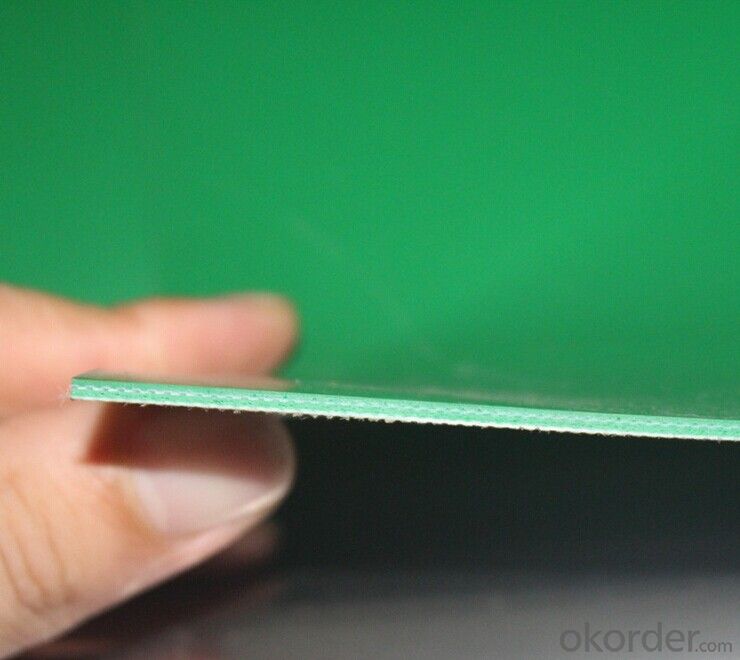

Thickness: 0.8~5MM customization

Maximum width: 4000MM

Strength: can be customized according to requirements

Conveyor Belt Specifications

Thickness: PVC Belting (1~7mm) PU Belting (0.8~4mm)

Width: 200mm ~ 4000mm

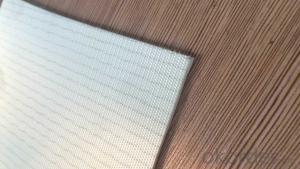

Appearance: Flat surface, diamond pattern, lawn pattern, golf pattern,etc.

Colors: Green, blue, gray, white, black, blue, dark green, transparent,etc.

Subsequent machining technology: It can add baffle, skirt, sponge, guide bar,etc.

Application:

PVC Belting: Food, medicine, electronics, tobacco, printing, packaging, textile and other production lines.

PU Belting: Most applicable to the food industry and other industries .

Working environment:

1. the working environment, conditions and conditions

2.Need to consider the time of day every day operation, the operating frequency, the service life of the belt conveyor, feeding and unloading methods.

3.Work environment, conditions: ambient temperature, outdoor or indoor, environmental requirements, mobile or fixed, telescopic requirements.

Conveyor Belt Application

Food conveyor belt

Plate conveyor belt

Printing machine of conduction band

Oil resistant conveyor belt

Knife edge conveyor belt

Conveyor Belt Photos

FAQ

Q: Can you do OEM?

A: Yes, we can do OEM products based on your requirements.It's no problem.

Q: How can I get some samples?

A: 1, We are honored to offer you samples. New clients are expected to pay for the courier cost, the samples are free for you, this courier cost charge will be deducted from the payment for formal order.

2, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS, DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you can pay the freight direct to your local carrier company.

Q: How do you do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to the very end:

1)All raw material we used are environmental-friendly;

2)Skilful workers care every details in handling the producing and packing processes;

3)Quality Control Department specially responsible for quality checking in each process.

Q.What are your payment terms?

A: Standard payment terms are 30%T/T,and balance payment before shipment.

L/C at sight is acceptable

Other payment terms can be negotiable.

If you want to find more details about the PVC conveyor belt, you could make an Inquiry in okorder.com. Okorder.com provides you the products with best price and quality!

- Q:Can olive nets be used to improve the profitability of olive farming?

- Yes, olive nets can be used to improve the profitability of olive farming. Olive nets are designed to protect the olives from pests, birds, and excessive sunlight, which can lead to a higher yield and better quality olives. By preventing damage to the olives, farmers can maximize their harvest and increase their profits. Additionally, olive nets also simplify the harvesting process by collecting the olives in a convenient manner, reducing labor costs and increasing efficiency.

- Q:How does an olive net affect the overall labor costs of harvesting?

- An olive net can significantly reduce the overall labor costs of harvesting. By using a net to catch the falling olives, it eliminates the need for manual picking, saving both time and labor. This mechanized approach allows for more efficient harvesting, reducing the number of workers required and lowering labor costs.

- Q:Can olive nets be used for olive tree bonsai training?

- Yes, olive nets can be used for olive tree bonsai training. Olive nets can help support and shape the branches of the bonsai tree, allowing it to grow in a desired direction and form.

- Q:Are there any regulations or guidelines for using olive nets?

- Yes, there are regulations and guidelines for using olive nets. These regulations may vary by region or country, but they typically cover aspects such as the size and mesh of the net, installation and anchoring methods, and the duration of net usage. They are in place to ensure the protection of olive trees, prevent damage to the fruit, and promote sustainable harvesting practices. It is advisable to consult local agricultural authorities or olive farming associations for specific regulations in your area.

- Q:Scope and characteristics of plastics No. 7

- Pay special attention to the use of this plastic container. Bisphenol A residues in PC, the higher the temperature, the faster speed of release. Therefore, hot water should not be used in PC bottles. If your kettle number is 07, the following methods can reduce the risk: do not heat when using, do not direct in the sun. Don't use a dishwasher and a bowl machine to clean the kettle. Before using for the first time, rinse with baking soda and warm water and dry naturally at room temperature. If the container has any falls or breakage, it is recommended not to use it because the surface of the plastic is prone to contain bacteria if there are fine pits. Avoid repeated use of aged plastic appliances

- Q:When was plastic invented?

- The plastic is made of monomers as raw materials, polymer by polyaddition or polycondensation polymerization (macromolecules), commonly known as plastic resin (plastics) or (resin), can freely change the composition and form style, composed of synthetic resin and filler, plasticizer, stabilizer, lubricant, pigment and other additives.

- Q:Are there any specific guidelines for removing olive nets without damaging the trees?

- Yes, there are specific guidelines for removing olive nets without damaging the trees. Some of these guidelines include: 1. Start by carefully untangling any netting that may be caught on branches or leaves. Take your time to avoid pulling or tearing any part of the tree. 2. Remove the netting from the top of the tree first, gently lifting and folding it back to avoid any sudden movements that could harm the branches. 3. Gradually work your way down the tree, folding and rolling the netting as you go. It is important to avoid any jerking or pulling motions that could break branches or cause damage. 4. If the netting is tightly tied or stuck to the branches, use scissors or a knife to carefully cut it away, ensuring not to cut into the tree itself. 5. Once the netting is completely removed, inspect the tree for any signs of damage or stress. If any branches are broken or injured, prune them carefully to promote proper healing. By following these guidelines, you can safely remove olive nets without causing harm to the trees.

- Q:Can olive nets be used for olive trees in pots or containers?

- Yes, olive nets can be used for olive trees in pots or containers. Olive nets are typically used to catch falling olives during harvest, but they can also provide support to olive trees in pots or containers by preventing branches from drooping or breaking under the weight of the fruit.

- Q:How do olive nets affect the development of olive tree trunks?

- Olive nets do not directly affect the development of olive tree trunks. However, they play a crucial role in protecting the olives from being eaten by birds or other animals, ensuring a successful harvest. By covering the trees with nets, the fruits remain intact, allowing the tree to allocate its resources towards the growth and development of the trunk and branches.

- Q:Can olive nets be used in hilly or sloping terrains?

- Yes, olive nets can be used in hilly or sloping terrains. The nets can be secured or anchored to the ground to prevent them from sliding or moving on the slopes. This helps to protect the olives from rolling down the hill and ensures efficient harvesting.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Food Industry White Food Grade PVC PU Conveyor Belting

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords