Food Grade White PVC Conveyor Belt PU Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Food Grade White PVC Conveyor Belt PU Conveyor Belt

Light Duty Conveyor Belts for food industry are excellent resistant to oil and fat, non-toxic, healthy and easy to clean. The type of belts conforms with FDA, USDA and EU regulations, can be used in many applications in the following industries: bakery, confectionary, meat and poultry, fish, fruit and vegetables, dairy, agriculture etc.

With advanced coating machine and other excellent facilities, we are professionally producing PVC&PU light conveyor belts, which are extremely suitable for light industry such as beer industry, paper making industry, food industry, textile industry etc.

PVC/PU conveyor belt/FDA

1. material: PVC/PU

2. color: white,dark green,sky bule,etc

3. surface: smooth,matt

4. thickness:2mm/2.5mm/3mm/as request

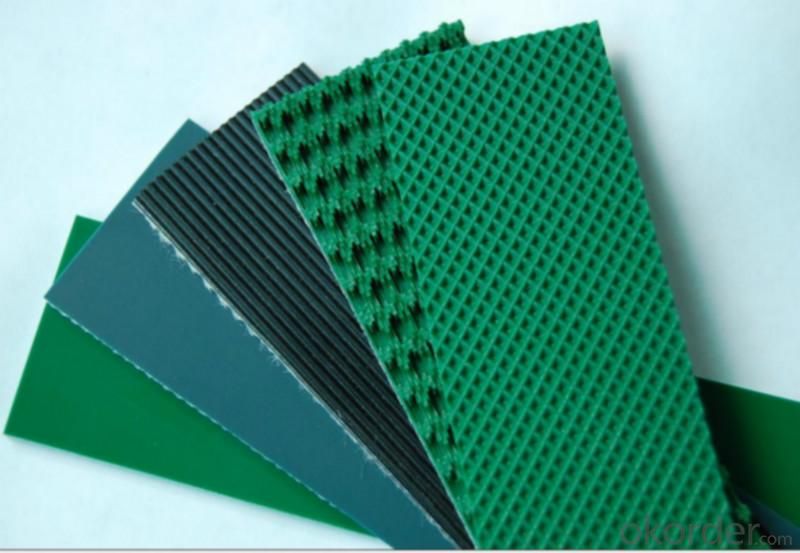

PVC conveyor belt

No. of fabric plies:1, 2, 3, 4 ,5ply.

Surface:smooth,matt,diamond,rough,etc.

thickness:1mm-8mm

Features:

1)Low stretch;

2)Low maintenance;

3.Anti-static;

4)Flexible;

5.Lightweight;

6)Impervious to moisture,acids,oils,gases,sunlight;

7)Excellent fastener holding;

8)Excellent resistance to tearing,peeling and impact;

9)Endless belt splicing;

10)Special wear resistant edge design;

Product Photos

For more informations,please contact us freely,thank you.

- Q:How do olive nets impact the overall water requirements of the olive tree?

- Olive nets can have a positive impact on the overall water requirements of the olive tree. By covering the tree and preventing evaporation, the nets help conserve water and reduce the amount of irrigation needed. Additionally, the nets also protect the tree from excessive sun exposure, which can lead to water stress. Overall, olive nets can help optimize water usage and promote healthier growth of the olive tree.

- Q:Is it harmful to health to drink water with plastic cups?

- Plastic space cup and soybean milk machine are the most dangerousExperts say, the plastic bottle has a big problem is that many people use space cup, space cup tea, high temperature, easy to release bisphenol A, "in fact also should pay more attention to space cup, this is very dangerous." As for drinking buckets, mineral buckets, mineral water bottles, such as the use of plastic products at normal temperatures do not have to worry about, he pointed out that these drinking water bottles generally do not need bisphenol A, and most are used at room temperature. "Too transparent mineral water bottles should also pay attention to, probably also contain bisphenol A", and if mineral water bottles are as transparent as glass, we should pay attention to.

- Q:Can olive nets be used for ornamental olive trees?

- Yes, olive nets can be used for ornamental olive trees. Olive nets are commonly used to protect olive trees and their fruit from birds, so they can also be used for ornamental olive trees to prevent bird damage and ensure the tree's aesthetic appeal.

- Q:How does an olive net affect the overall fruit flavor in the olive grove?

- An olive net can have a positive impact on the overall fruit flavor in the olive grove. By preventing the olives from falling to the ground and potentially getting damaged or contaminated, the net helps maintain the quality of the fruit. This results in a more consistent and flavorful harvest, as the olives remain untouched and free from any potential negative influences.

- Q:What is the purpose of using an olive net?

- The purpose of using an olive net is to collect olives during the harvesting process. The net is spread out under the olive trees, acting as a catchment system to prevent the olives from falling to the ground and getting damaged. This allows for easier collection and minimizes waste, ensuring a more efficient and productive olive harvest.

- Q:How do olive nets prevent olives from getting sunburned?

- Olive nets provide shade and protection to the olives, which prevents direct exposure to the sun's intense heat and ultraviolet (UV) rays. This helps to avoid sunburn on the olives, which can lead to reduced quality and yield.

- Q:Can olive nets be used on olive trees grown in pots indoors?

- Yes, olive nets can be used on olive trees grown in pots indoors. Olive nets are typically used to protect the olives from birds and other animals when they are grown outdoors. However, if you have an olive tree in a pot indoors and you want to protect the olives, you can still use olive nets to prevent any unwanted damage.

- Q:How does an olive net affect the quality of the olive oil produced?

- An olive net can positively affect the quality of olive oil produced by preventing the olives from falling onto the ground and being exposed to potential contaminants, such as dirt or pests. By keeping the olives clean and intact, the net helps maintain their freshness and minimize the risk of spoilage. Additionally, the net can prevent damage to the olives during harvesting, preserving their overall quality and ensuring a higher yield of premium olives for oil production.

- Q:Can olive nets be used to improve fruit size?

- Yes, olive nets can be used to improve fruit size. By covering the olive trees with nets, they protect the fruits from external factors such as pests, birds, and extreme weather conditions. This allows the olives to grow undisturbed and reach their full potential in terms of size and quality.

- Q:How do you remove olives trapped in the net?

- To remove olives trapped in the net, gently untangle the netting from around the olives one by one, being careful not to damage the olives or the net. If needed, use a small pair of scissors to carefully cut away any tangled portions of the net.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Food Grade White PVC Conveyor Belt PU Conveyor Belt

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords