Food Grade PVC Conveyor Belt Smooth Diamond Green/White/Blue

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Food Grade PVC Conveyor Belt Smooth Diamond Green/White/Blue

Our company production of food-processing conveyor belt choose high quality high strength polyester fabric as the core, good flexibity, using environmental PU and PVC as the material of conveyor belt, one of them, the PU belt not only have common character of conveyor belt hight tensile stength, light, thin, but also oil-resistant, abrasion-resistant, non-toxic.The above could meet the food grade standards,and could contact with food,no peculiar smell.

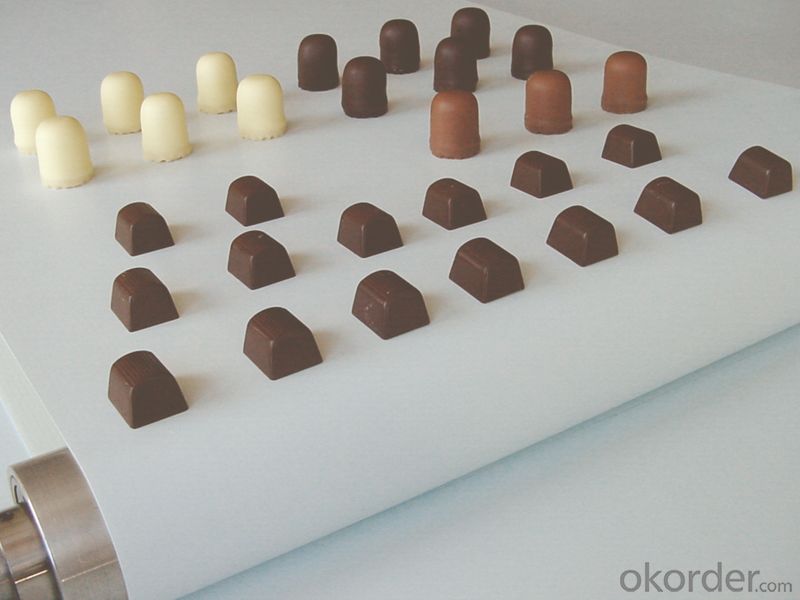

Light Duty Conveyor Belts for food industry are excellent resistant to oil and fat, non-toxic, healthy and easy to clean. The type of belts conforms with FDA, USDA and EU regulations, can be used in many applications in the following industries: bakery, confectionary, meat and poultry, fish, fruit and vegetables, dairy, agriculture etc.

We can divide the conveyor belt into three categories: PVC conveyor belt, PU conveyor belt and some special material, such as silica gel, rubber.

conveyor belt fabric layers: A layer of cloth and a layer of glue, two layers of cloth and two layers of glue, three layers of cloth and three layers of glue, and so on. It can be customized according to your requirements.

Colors: red, yellow, green, blue, gray, white, black, blue, green, transparent (in general we have)

Thickness: PVC (1~7mm) PU (0.8~4mm)

Appearance: flat surface, diamond pattern, lawn pattern, golf pattern etc.

Advantages: PVC: economical and practical, technology is mature.

PU: applicable to the food industry, abrasion resistant and corrosion.

Subsequent machining technology: it can add baffle, skirt, sponge, guide bar.

Feature Food PVC Conveyor Belt:

1.Natural rubber thin belt body with high strength, light weight;

2.Anti-abrasive, impact resistant, corrosion resistant;

3.Softy belt body, good flexibility, excellent trough;

4.Vulcanization molding;

5.Long service life.

Photos of Food PVC Conveyor Belt

FAQ

Q: Can you do OEM?

A: Yes, we can do OEM products. It's no problem.

Q: How can I get some samples?

A: 1, We are honored to offer you samples. New clients are expected to pay for the courier cost, the samples are free for you, this courier cost charge will be deducted from the payment for formal order.

2, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS, DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you can pay the freight direct to your local carrier company.

Q: How do you do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to the very end:

1).All raw material we used are environmental-friendly;

2).Skilful workers care every details in handling the producing and packing processes;

3).Quality Control Department specially responsible for quality checking in each process.

Q.What are your payment terms?

A: Standard payment terms are 30%T/T,and balance upon the B/L copy .

L/C at sight is acceptable

Other payment terms can be negotiable.

If you want to find more details about the PVC conveyor belt, you could make an Inquiry in okorder.com. Okorder.com provides you the products with best price and quality!

- Q:Are olive nets suitable for organic farming practices?

- Yes, olive nets are suitable for organic farming practices. They are commonly used in organic olive farming to protect the trees and harvest the olives without the use of chemical pesticides. Olive nets help prevent pests and birds from damaging the crop, ensuring a more sustainable and natural farming approach.

- Q:Can olive nets be used for other types of edible oil production?

- No, olive nets cannot be used for other types of edible oil production as they are specifically designed and tailored for harvesting olives.

- Q:How does an olive net affect the overall labor costs of harvesting?

- An olive net can significantly reduce the overall labor costs of harvesting. By using a net to catch the falling olives, it eliminates the need for manual picking, saving both time and labor. This mechanized approach allows for more efficient harvesting, reducing the number of workers required and lowering labor costs.

- Q:Can olive nets be used on trees of different ages?

- Yes, olive nets can be used on trees of different ages. Olive nets are designed to protect the olive fruits from birds and other animals. These nets can be draped over the trees, regardless of their age, to prevent the fruits from being eaten or damaged.

- Q:Can olive nets be used in regions with limited access to water resources?

- Yes, olive nets can be used in regions with limited access to water resources. Olive trees are known for their ability to withstand drought conditions, requiring less water compared to many other crops. Additionally, the use of olive nets helps to retain soil moisture and reduce evaporation, making them suitable for regions with limited water availability.

- Q:What does Tupperware cup other7 stand for?

- PET (polyethylene terephthalate), a container made of this material is commonly installed plastic soda bottles, also known as the "bottle".Common mineral water bottles, carbonated beverage bottles, etc.. Heat resistant to 70 degrees, easy to deformation, there are harmful substances melting. After 1 months with plastic, may release a carcinogen, DEHP. Can not be put in the sun in the car; do not install wine, oil and other substances

- Q:How do olive nets affect the development of olive tree branches?

- Olive nets have a significant impact on the development of olive tree branches. When olive nets are used, they provide protection to the branches, shielding them from external factors such as wind, animals, and pests. This protection allows the branches to grow and develop without being damaged or broken, resulting in healthier and stronger branches. Additionally, olive nets also help in optimizing the distribution of sunlight and airflow, promoting proper photosynthesis and reducing the risk of diseases. Overall, olive nets play a crucial role in supporting the development and growth of olive tree branches.

- Q:Can olive nets be used for olive tree propagation from saplings?

- No, olive nets are typically used for harvesting olives from mature trees, not for the propagation of olive trees from saplings.

- Q:How do you prevent olive nets from causing damage to surrounding vegetation or wildlife?

- One way to prevent olive nets from causing damage to surrounding vegetation or wildlife is by using properly designed and installed nets. These nets should have a fine mesh size that prevents small animals or birds from getting entangled and should be securely fastened to avoid them being blown off by wind or causing any unintentional harm. Additionally, regular monitoring and maintenance of the nets can help identify any potential issues or damages, allowing for timely repairs or adjustments to minimize any negative impact on the surrounding environment.

- Q:Can olive nets be used in combination with shade nets?

- Yes, olive nets can be used in combination with shade nets. Olive nets are typically used to protect olives from birds and other animals, while shade nets are used to regulate sunlight and temperature. By using both nets together, olive crops can be protected from pests and birds, while also maintaining the desired level of shade and temperature.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Food Grade PVC Conveyor Belt Smooth Diamond Green/White/Blue

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords