Food Grade CMC Carboxymethyl Cellulose FH6

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

| Food Grade CMC Used as additive in food field, CMC has the functions of thickening, suspending, emulsifying, stabilizing, shaping, filming, bulking, anti-corrosion, retaining freshness, acid-resisting, health protecting, etc. It can replace the application of guar gum, gelatin, agar, sodium alginate, and pectin. It is widely used in modern food industry, such as frozen food, solid drink, fruit juice, jam, lactic acid drinks, condiment, biscuit, instant noodles, bakery products, meat products, etc. Our food grade CMC has good thickening property, water retention, dispersion stability, filming and chemical stability. It has high viscosity even in low concentration, and makes the food taste delicate and smooth; it can reduce the syneresis of food and extend the shelf life; it can control the crystal size in frozen food and prevent the stratification between oil and water; In acid system, our anti-acid products have good suspending stability, so it can improve the stability of milk and the impedance ability of protein; our CMC can be used together with other stabilizers and emulsifiers to complement each other, strengthen each other’s effect and reduce the cost. |

|

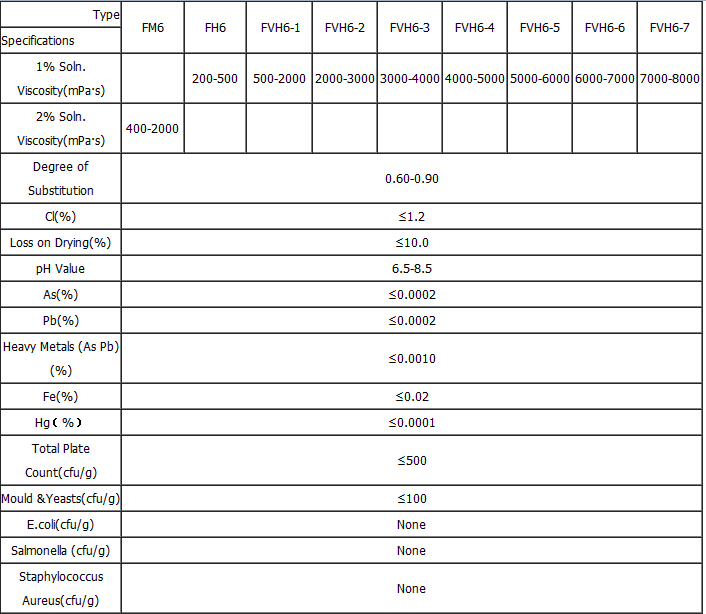

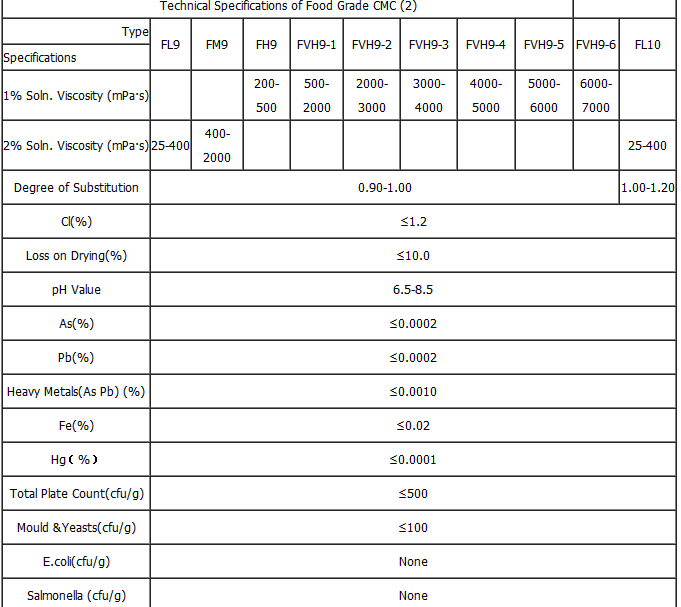

Technical Specifications of Food Grade CMC(1)

|

|

- Q:Pig feed additive formula

- Significantly improve the lean meat rate, fat-free lean meat growth rate increased by 33%, improve the pig meat carcass lean meat rate and eye muscle area, improve the slaughter rate, significantly improved pig appearance, back wide back ditch deep, abdomen flat, Muscular, leg fullness.

- Q:just dubai please.i could‘nt find the information

- land such as dirt or soil

- Q:As you can tell my piston rings are worn and I have blue smoke going everywhere. I just switched out the oil and went with a thicker weight and put in some bardahl stop leak additive but after a few start ups the car is still smoking. I was wondering if there was a specific amount of mileage that is needed in order for the additive to flow through the engine to temporarily stop the leak or if there was another brand of additive that‘s better or if additives just don‘t work. I realize that eventually ill have to rebuild the engine but I‘m just trying to buy some time here. Thanks.

- the money you will spend for additives and some trial and error repair, plus the oil to top the level, just save it for engine rebuilding. no additives can fix, weld, build up a broken/worn out piston rings and sleeves/cylinders. and no oil can restore the flexibility of valve seals, cam seals, and crankshaft seals when it starts to leak.

- Q:Have you heard this news report about McDonalds Chicken Sandwiches, allegedly made with a petroleum additive?

- There are lots of things in a lot of foods that would make people cringe. It makes you really wonder about disease and why a cure for many are never allegedly found. Think about it. It's all about the almighty buck and not the health of people. As for China, being that the U.S. government just had the big thing about lead in Chinese made toys and other products, it make sense that the Chinese would attack an American empire like McDonalds. But yet American retailers buy and sell so many products from China. Why? Because it's so much more inexpensive and also very cheap in quality. Remember it's all about the almighty buck. The so-called global economy will be the downfall of the world eventually.

- Q:I found out that beer companies have lobbied so that they don‘t have to list their ingrediants on the bottle. Do you know of any websites that lists the ingredients?

- They shouldn't have additives at all. As for recipes, there are a lot of things that can be used but the normal ones are malted barley, hops, and yeast. There have been companies that use rice (Budweiser) corn, wheat, and rye. German beers by law, if memory serves me right, can only have those three base ingredients. The links can give you an idea of the diversity of types of beer and how you can make them.

- Q:I am actually trying to dye my hair purple. I just bought Chi Purple Color Additive and Chi Dark Ash Ash Blonde dye with 10 Volume Chi Color Generator. I currently have long ombre hair, light/medium brown near the roots and blonde at the tips. I prefer not to make my hair darker, and I prefer not to bleach it. Does anyone know how it would turn out if I mixed the Dark Ash Ash Blonde and the purple additive?

- I've never heard the term Color Additive before, but I'm assuming it is just Chi's attempt at giving a toner a fancy name. A purple toner will not make your hair purple at all. It would just cancel out any brassy tones, which you shouldn't be getting anyway from a color described as ash ash. You need to buy purple dye. Manic Panic and Splat are popular brands.

- Q:The sum of additive inverses is always zero. True of False?

- the sum of any additive and its inverse is always zero: x + (-x) 0

- Q:a)0 b)2 c)5 d)-4i know its not -1 or -4 since1 * -1 equals -1 and 2 * -2 equals 4so what is it guys?also, here's a few more questions (yes i know, im stupid)1. a perfect square is the product of any integer and itself. how many perfect squares are factors of 2x4x6x8x10?a) 5 b)4 c)3 d)22. if the circumference of a circle is 4cm, its area is ___cm^2.a) 4/pi b)16/pi c)4pi d)16 pi3. if n is a whole number, which of the following could equal n^3?a) 2.7x10^27 b)2.7x10^28 c)2.7x10^29 d)2.7x10^304. a right triangle can have at most ___ of length 5.a) 3 sides b) 2 sides c) 1 side d) 0 side5. if i add the digits of my phone's extension number, i get 28. the numbers can't have __ digits.a) 3 b)4 c)5 d)7explanations would be nice. (:if you can just answer the most you can, it'd be appreciated.thank you.

- It never equals 0 because 0 has to be one of the factors and it doesn't have an additive inverse :-) 1. 4,16, and 64 are all perfect squares. I can't think of any others that would be factors of that number. 2. The formula for the area of a circle in number 2 is pi * r^2. Take the radius and square it and multiply by pi. 3. 2.7 x 10^27 is the same as 27 x 10^26. 27 has a cubed root, but 10^26 doesn't. Therefore this is not the answer. 2.7 x 10^28 is the same as 27 x 10^27. Both of these numbers have cubed roots. 2.7 x 10^29 and 2.7 x 10^30 are 27 x 10^28 and 27 x 10^29 respectively. Neither of these have all the terms which have cubed roots. 4. Number 4 you should be able to cut some straws to a length of 5 cm or 5 inches or something. Then experiment with them and see if you can get all three of them to form a triangle (keeping 2 of them at right angles) or if you need one or two or all of them to be shorter or longer. 5. Sorry, can't help you with the last one.

- Q:I was wondering if the Republic Tobacco company has any additives in it. If they do, are Top rolled cigarettes healthier than mainstream cigs like Camel or Marlboro?

- Nitrogen expands just like air when heated. The benefits of using Nitrogen is to prevent pressure loss due to leakage. In all honesty your money would be better spent on buying a good tire pressure guage and checking the pressure every time you fill up with gas or at least once a month. j

- Q:(1) 0(2) 1(3) -1(4) there is no such real number

- I think the last time I changed them was in 1979!!!!! Wow! Maybe it's time!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Food Grade CMC Carboxymethyl Cellulose FH6

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords