Floor Tiles/Standard Size Polished Glazed Cement Tile

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 Square Meters other m²

- Supply Capability:

- 5000 Square Meters per Day other m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

1-Full polished glazed cement tiles

2-W.a: E<0.1%

3-60X60 CM

4-style:marble look design

5-Manufactory derict supply

product Description

Size |

600X600mm(23"X23"inch) 800X800(34X34"inch) |

Color |

Grays/yellows,brawns,grays;Red; White etc |

Water -absorption rate |

E<0.1% |

Abrasion strength |

PEI4,5 |

Thickness: |

10mm+/-0.2 |

Quality |

Class A |

Usage |

Home,office building,hotel;projects , flooring;and indoor or outdoor wall tile |

Packing Information

| Size | PCS/CTN | KG/CTN | CTN/PLT | PLT/FCL |

600X600(23"X23"inch) | 4 | 30 | 40 | 20 |

| 800X800(34X34"inch) | 3 | 45 | 28 | 20 |

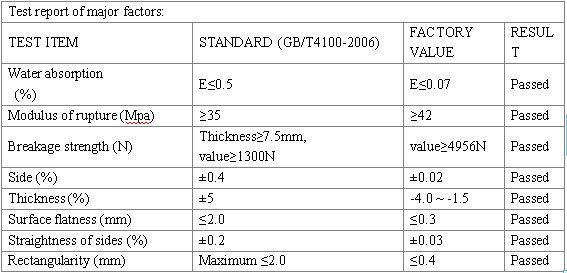

Test report

- Q:i hire a contractor to replace and removed the old siding form my house. i have seen siding install before and there is normally an woord frame or plywood that is underneat the siding. the contractor stated that is no needed. and based on that he refused to continue with the work. i then proceeded to put a stop payment on the downpayment what are my options now! can i hired someone else to do the work without bein held liable for his expenses?

- he removed the old siding and found no wall sheathing? ( plywood) and then started to install new hardiplank? so he just put back like it was before but with diff. type of material... hmmm, unless it was stated in the contract that he was to bring the exterior up to code then, ur in the wrong.....now, u can go after him by reading up on the material, hardiplank, and see if it states that there must be a solid backing or wall sheathing under the siding! if so u got him there for wrongful installation...... either way he should have told u when he found no sheathing under the old siding what was going on....how old is the house and where do u live ( state).....email me for more help.... lic. gen. contractor

- Q:Im in the middle of a renovation and the tiler has told me that Natural stone tiles 18x18 should not be installed on a cement board wall that has been primed. This application is for a shower/steam room. He has told me that i should rip down the cement board and replace with new unprimed boards. Any advice. The tile is planning on using Flextile 52. Please advice if the boards need to be replaced. The cement board has had the screws and joints covered with drywall cement and then the entire wall was painted with drywall primer sealer (latex).Thanks

- you will be fine. if you want take a steel brush and brush some of the primer if the tile guy is that persistant

- Q:Im in the middle of planning to build a deck I'm my backyard and was looking through materials and noticed that concrete and cement were listed differently and that concrete was twice as expensive as cement. I'd always thought they were the same so I was just wondering what the differences were and how they work differently.

- Cement is the grey powder that you buy in a bag. You mix this cement with sand, gravel and water to make concrete.

- Q:I need a 20 ft by 16 ft concrete pad for a pavilion. Should I use a concrete truck or quikrete? Costs are a factor.

- The third option is mixing up your own concrete from Portland Cement, gravel and sand aggregate. That will be much cheaper than Quikrete, and probably a bit cheaper than a ready-mix truck. It's really the only way to go if truck access to the site is poor, or if you don't want to tear up the adjacent grass too much.

- Q:why are cement factories important for the economics in uae?

- cement is one of many things that are necessary for oil production and all construction.

- Q:My son is nine and some kids his age are using the cement job. Not just from the neutral positon but from top to. I need some help on ways to keep him out of it and maybe counter itif at all possible.

- Every move has a different name, but judging from the description you gave me I think I know what you're talking about. To counter a cement job you have to pinch down on the arm, release it into the air, and break free. This is a hard move to counter because of the suppression on the throat, but can be done. If you are unsure what I mean by pinching the arm it's when your opponent has you in a headlock and is trying to punch through for the pin, tuck the arm he is trying to punch through with into your body. This will cause pressure, and he will be unable to run it correctly. My favorite move is the cement job =)

- Q:Hello, I have a paper stencil that I want to use to paint on a design on a block of wood that have that's painted with acrylic paints. If I glue down small portions, when I peel it off, will the paint me ruined? Would Elmer's school glue work better?

- You will want to use an oil-based paint if it is going to be outside. If it will be inside, then you can use either latex or acrylic. Acrylic will last longer, though. So, I think you are on the right track.

- Q:..........without having to make up more cement and putting that over it?I cemented an area on an outside wall and when I checked it a few days later, someone had drawn on it so now it has set and I can't get rid of it. I don't want to have to buy more cement so wondered if there's some way of getting rid of the picture without having to cement over it.

- There are a couple of things to try. The first and cheapest is to get out there with a scrub brush, soap, and water. If that doesn't work, get some rubber gloves and scrub with paint thinner. The more costly but most effective option is to have the concrete sand blasted. That's generally how they remove graffiti from wall made of brick or cement. As stated, it's very effective.

- Q:What kind of cement (and where can I get it $$$$) can I use to replace it without going back to the dentist?

- You cannot re cement it by yourself. It is even a tricky procedure for the dentist to properly do and he has several different types of materials he can decide to use. Do the job right and see a professional. It is not that costly.

- Q:Please any one says me Chemical composition of Portland cement?

- Typical constituents of and Portland cement Mass% Calcium oxide, CaO 61-67% Silicon oxide, SiO2 19-23% Aluminum oxide, Al2O3 2.5-6% Ferric oxide, Fe2O3 0-6% Sulfate 1.5-4.5%

Our main products include calicium silicate boards, mineral fiber boards and T-grids. With advanced technology, a complete quality system and good inspection methods, the quality of our product is first-class and reliable. Our products fit for the developing direction of building materials, namely: environmentally-friendly and energy saving. It is a kind of first-selected environmentally-friendly building material of the 21st century.

1. Manufacturer Overview |

|

|---|---|

| Location | Hebei,China |

| Year Established | 2006 |

| Annual Output Value | Above US$15 million |

| Main Markets | Asia, Middle East |

| Company Certifications | CE, CCC, ISO90001 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 0.3 |

| No.of Employees in Trade Department | 4 People |

| Language Spoken: | English;Chinese;Arabic |

| b)Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Floor Tiles/Standard Size Polished Glazed Cement Tile

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 Square Meters other m²

- Supply Capability:

- 5000 Square Meters per Day other m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords