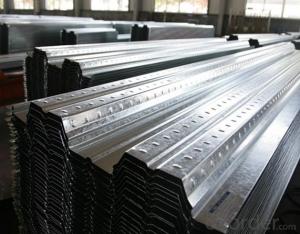

Floor Decking Steel Panel with good quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Sichuan China (Mainland) | Brand Name: | Baoye | Model Number: | BYF2 |

| Material: | Galvanized Sheet |

Packaging & Delivery

| Packaging Detail: | standard export package |

| Delivery Detail: | 20 days after downpayment |

Specifications

Floor decking steel panel is formed by floor deck forming machine, use galvanized steel at thickness 0.7-1.2mm

Floor decking steel panel is formed by floor deck forming machine, use galvanized steel at thickness 0.7-1.2mm, put the panel on the supporting H-beam, fill cement on it. It is mainly used as the floor of multiple floor buildings, it can lighten the weight and save with same loading capacity.

1.Strong friction and shear performance

The closed-type floor decking sheet uses special closed rib design and its vertical shear performance is good . Under the limitation allowance of the truss floor deck’s design loads,steel deck and concrete don’t slip off each other.

2.Perfect fire-resistant performance

Rib is completely encased in concrete,similar t reinforcing steel bars in the concrete slab which is site pouring.The closed-type composite slab can completely substitute the sagging moment reinforcing steel bars for pulling in the floor and can be up to 1.5 hours of fire-retardant coating .

3.Excellent floor decking sheet section

The closed-type composite slab has greater effective height,during the stage of use,it can provide greater resistance to sagging moment.

4.Slot-tye suspension system at the end of sheet

It is for the installation of ceiling,hung ceiling,water and electricity pipe,etc,without drilling,welding,during the stage of using,it can be moved,removed and reinstalled as needed.

5.East and fast to construct

It does not require any plug at the end ,and there is no leakage of plasma phenomena,it can shorten the construction period.

6.Flat appearance f the end of sheet

The end of slab is flat and beautiful for the building which don’t want ceiling.

7.Effectively reduce the height of the sheet

According to the requirement of fire safety and anti-tremor,the total thickness of the closed-type corrugated floor decking sheet is only 110-130mm,30-40mm less than the open-type,so it reduces the weight and cost and add the net height.

8.Low cost

The closed-type pressure plate can substitute the sagging moment reinforcing steel bars at the end of sheet,and there is no need to paint any fire-retardant coating,it reduces the steel amount and then lowers the cost.

- Q:What is the quality of the board?

- The use of environmental protection factor is higher than the national standard 18mm thickness of the MDF, and the new PVC louver with a different from the general wood sheet of polymer synthetic fiber material, after 200 degrees Celsius Of the high temperature without plastic hot veneer treatment, completely free formaldehyde release. This ensures that the production of "starting line" to reduce the formaldehyde content. The quality of formaldehyde is less than or equal to 1.5mg / L, and the formaldehyde content of E1 grade (national mandatory standard) is less than or equal to 1.5mg / L

- Q:Jumping rabbit plate quality is good

- Jumping rabbit plate good rubber is not how kind, thin, but also with a little edge skin, the overall use of the down is not how

- Q:What are the plates?

- Usually made of standard size flat rectangular building material board, as a wall, ceiling or floor components. Also refers to the forging, rolling or casting made of metal plate. Divided into thin plate, medium plate, thick plate, special thick plate, usually made of standard size flat rectangular building material board. According to the material classification can be divided into solid wood, wood-based panels two categories; according to the classification can be divided into solid plate, plywood, fiberboard, decorative panels, fire board, particleboard and so on.

- Q:I went to the optical shop to see the frame, the shopkeeper asked me to be good or the general, I said a little better when he took me a pure titanium, and asked the price surprised. I find a pick when he said, he said that the plate, the price is more than 100 I now use the plastic, the frame to buy when only 20 yuan. In the end what kind of frame should be good for it? I hope the price will not exceed 150 yuan

- Frames should be based on the face of the selection; face thin with a thin point of the frame is better. But also with the length of time wearing glasses also have to contact every day wearing a long time to choose a light point of the glasses, to avoid the nose pressure change type. In fact, the most important thing is the lens, the quality of things now vary widely, you have to choose a high light, wearable, safe, and their favorite. Also, male and female wear frames are not the same. Pure titanium, high-grade some corrosion-resistant, but also anti-magnetic. Large face of the plate do not use, round face is not appropriate. It is best to wear to see.

- Q:Bookcase with what the best plate

- It is best to use a fir fingerboard for a bookcase and a wardrobe. Environmental protection and beautiful, direct brush on the varnish, very kind of living in the pastoral fresh gas. But there is little change that is. Wardrobe doors need to use woodworking board or three-layer composite finger plate to do. And the bare part of the backplate is reinforced with white pine keel. This will avoid cracking. Another kind of cracking may refer to the board failure, moisture content is relatively high. Therefore, it is recommended that you use a good quality plate, home improvement commonly used brands are Moganshan and bunny. You can also use Jiangxi 100 source. The quality of the king coconut is not evaluated. I wish you a pleasant decoration.

- Q:Who has a natural marble sheet testing report template?

- Main Test Products Main Testing Products Granite Granite Marble Marble Quartz Stone Quartz Limestone Slate Roofing slate Complex veneer thin stone Artificial marble Artificial quartz stone Artificial quartz stone The following are the same as the " Main Testing Scope Visual dimensions and dimensions Petrographic analysis Gloss Gloss Water absorption Density Flexural strength Compressive strength Thermal shock resistance Abrasion resistance Slip resistance Coefficient of friction Coefficient of friction Frost resistance Fire to Reaction Shore hardness Mohs hardness Mohs hardness Acid resistance Radioactive radioactivity

- Q:What are the characteristics of KRD blue epoxy sheet?

- "KRD blue epoxy plate" in 1938 by the German company in Switzerland patent application in Switzerland, 1946 secretly put into operation in the high-end military plate, in 2008 Germany Kerui De company in the original epoxy board formula based on improved by adding KRD blue Water resistant weather factor, to produce high-end "KRD blue epoxy plate", put the German market, mainly used in luxury cruise ships and high-end cars and high-end interior furniture production. October 2009 European style (Hong Kong) bathroom International Development Co., Ltd. formally introduced "KRD blue epoxy plate" production line into the civilian bathroom furniture production. ????"KRD blue epoxy sheet" has a strong chemical resistance and water resistance. In the curing system of ether, benzene ring and fatty hydroxyl is not susceptible to acid and alkali erosion. Can be used for two years in seawater, petroleum, kerosene, 10% H2SO4, 10% HCl, 10% HAc, 10% NH3, 10% H3PO4 and 30% Na2CO3, and half a year at 50% H2SO4 and 10% HNO3; % NaOH (100 ° C) for a month or soaked in fresh water for 50 years, the performance remains the same. ????"KRD blue epoxy plate" molecular chain structure contains two or more epoxy groups of polymer compounds, process performance is good, strong nail holding force, product size and stability, no radiation, zero formaldehyde, is the current The forefront of the international environmental health, strong weather resistance of high-end furniture preferred plate. "KRD blue epoxy plate" Appearance features: A high density light B The appearance of the plate is light blue C strong flexibility

- Q:What brand of furniture is good?

- Of course, is the choice of imported sheet is better, the furniture environmental performance is mainly reflected in the plate, a good plate formaldehyde content is particularly low, mainly divided into three, E2 level which is in line with domestic standards, E1 level in line with European standards, E0 level is the most Environmental protection of the world's top standards. Like Amoy home now launched the import board furniture package, have reached the EO level of the standard, recently also promotions, buy environmentally friendly furniture to pay attention to the issue, the first look at the color of the plate, pick their favorite popular colors, But also carefully look at the production process, including the edge, the furniture structure is reasonable, the use of hardware mainly focus on the durability factor, the general import of hardware life is 100,000 times, equivalent to two decades.

- Q:Are man-made sheets containing formaldehyde?

- Adhesive, with formaldehyde. No aldehyde glue seems not much. How much formaldehyde, and the quality and amount of glue. So buy the floor, pure wood the most environmentally friendly.

- Q:Home improvement wardrobe what brand plate best

- Custom cabinet, then the general is solid wood particle board (high density board), melamine board, particleboard. The advantages of this plate is the factory production, workmanship, the disadvantage is not enough nail force, a nail out of the words, you can no longer fixed. On-site cabinets are more common is the lacquered board and blockboard, deformation-resistant blockboard is better than the lacquer-free board. From the environmental aspects of the paint-free board is relatively better than the blockboard, because the blockboard with rubber is relatively more, but if you choose a good brand this is not how much the problem.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Floor Decking Steel Panel with good quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords