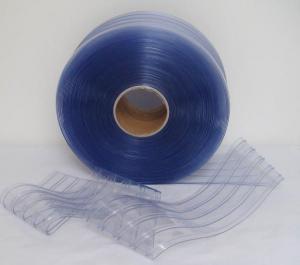

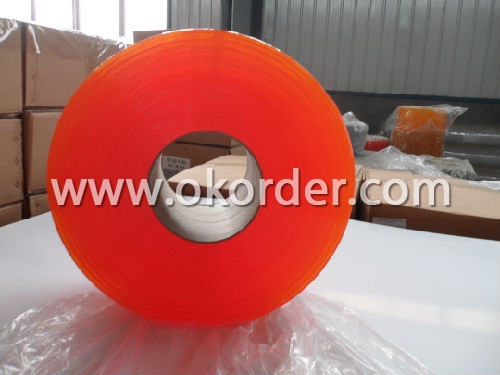

Flexible Anti Static PVC Strip Curtains

- Loading Port:

- TianJin

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 50 Rolls roll

- Supply Capability:

- 15 Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Flexible Anti-static PVC Strip Curtains

Application tempt range: -15℃to 50℃

Thickness range from 1.5mm to 6mm

Width range from 150mm to 400mm

Standard Sizes

2mmX200mmX50m; 2mmX300mmX50m;

3mmX200mmX50m; 3mmX300mmX50m;3mmX400mmX50m

4mmX300mmX50m; 4mmX400mmX50m

Applications of Flexible Anti-static PVC Strip Curtains

Widely used in electronics, food, pharmaceutical, refrigeration industry.

Can be used as barrier wall,protective portiere/curtain for sensitive area or protective cover for sensitive industry.

Package& Delivery of Flexible Anti-static PVC Strip Curtains

Wooden pallet,shirnk film according to custom requires.

Colors of Factory-sale Flexible PVC Strip Curtains

Green,Clear.

Data sheet of Flexible Anti-static PVC Strip Curtains

Performance Text | Standard Clear Formula | Cold Formula | Super Polar Curtain | Unit |

Softness A Hardness | 75+-5 | 65+-5 | 65+-5 | / |

Brittle Point | Approx -35 | Approx -45 | Approx -45 | Degress C |

Falling Ball Test | -20 No Break | -40 No Break | -50 No Break | Degress C |

Flexibility | -20 No Break | -40 Bo Break | -50 No Break | Degress C |

Water Absorption | 0.20% | 0.20% | 0.20% | % |

Tensile Stress | 340 | 420 | 420 | % |

Rupture Resistance | >5 | >2 | >2 | N/mm |

Reaction to fire | Self-Extinguishing | Self-Extinguishing | Self-Extinguishing | 0 |

Flammability | Inflammable | Inflammable | Inflammable | 0 |

Airborne Insulation | ~35dB | ~35dB | ~35dB | 0 |

Light Transmission | >80 | >80 | >80 |

- Q:How do home appliance plastics impact the overall cost of the appliance?

- Home appliance plastics can significantly impact the overall cost of the appliance. Plastics are often used in various components of home appliances due to their durability, light weight, and cost-effectiveness. By utilizing plastics, manufacturers can reduce the overall weight of the appliance, making it cheaper to transport and handle. Additionally, plastics allow for easier and more cost-efficient manufacturing processes compared to other materials like metal. However, the quality and type of plastics used can also impact the cost. High-quality, engineering-grade plastics may increase the price of the appliance, but they offer improved performance, longevity, and aesthetic appeal. In summary, the choice of home appliance plastics can play a substantial role in determining the cost of the appliance, balancing factors such as material quality, performance, and manufacturing efficiency.

- Q:Can plastic parts in home appliances be affected by exposure to extreme cold temperatures?

- Yes, plastic parts in home appliances can be affected by exposure to extreme cold temperatures. Cold temperatures can cause plastic to become brittle and more prone to cracking or breaking. Additionally, rapid changes in temperature can cause warping or distortion of plastic parts, which can impact their functionality. It is important to consider the temperature specifications and limitations provided by the manufacturer to ensure proper usage and prevent damage to plastic components in appliances.

- Q:Can plastic parts in home appliances be affected by humidity or moisture in the environment?

- Yes, plastic parts in home appliances can indeed be affected by humidity or moisture in the environment. Excessive moisture can cause plastic to absorb water, leading to swelling, warping, or deterioration of the material over time. This can impact the functionality and durability of these parts, potentially causing them to become brittle, crack, or fail. Therefore, it is important to protect home appliances from excessive humidity or moisture to maintain their performance and longevity.

- Q:How does the water resistance of plastic used in home appliances affect their performance?

- The water resistance of plastic used in home appliances is crucial as it helps to protect the internal components from damage caused by water or moisture. With good water resistance, appliances are less likely to malfunction or experience electrical failures due to water exposure. This ensures their overall performance remains reliable and efficient, extending their lifespan and providing a safe user experience.

- Q:What are the main factors considered when selecting plastic for home appliance production?

- When selecting plastic for home appliance production, the main factors considered are the material's durability, heat resistance, electrical properties, chemical resistance, and cost-effectiveness. Other factors include the plastic's ability to be molded into complex shapes, its aesthetic appeal, and its environmental impact.

- Q:Can home appliance plastics be easily cleaned and maintained?

- Yes, home appliance plastics can be easily cleaned and maintained. Most home appliances are made from plastics that are resistant to stains and easy to wipe clean. Regular cleaning with mild soap and water, or specific cleaning products recommended by the manufacturer, can help remove dirt, dust, and grime. Additionally, simple maintenance practices such as avoiding abrasive cleaners and keeping appliances away from heat sources can help prolong their lifespan and keep them looking new.

- Q:How does the tensile strength of plastic used in home appliances affect their resistance to stretching or tearing?

- The tensile strength of plastic used in home appliances directly affects their resistance to stretching or tearing. Higher tensile strength implies that the plastic can withstand greater pulling forces without stretching or tearing. This means that appliances made with plastic having higher tensile strength are less likely to deform or break under stress, enhancing their durability and longevity. Conversely, lower tensile strength plastics are more prone to stretching or tearing when subjected to external forces, which can compromise the functionality and lifespan of the appliances.

- Q:How do plastic home appliances compare in terms of energy-saving ratings?

- Plastic home appliances, like any other type of appliances, can have varying energy-saving ratings. The energy-saving ratings of plastic home appliances depend on various factors such as the design, technology used, and energy-efficient features incorporated. Therefore, it is not accurate to generalize all plastic home appliances as having similar energy-saving ratings. Consumers should always check the energy-saving ratings and labels provided by manufacturers to compare the energy efficiency of different plastic home appliances before making a purchase.

- Q:Can plastic parts in home appliances be affected by pests or insects?

- Yes, plastic parts in home appliances can be affected by pests or insects. Pests such as rodents or insects like ants and termites can chew through or damage plastic components, causing functional issues or even rendering the appliance unusable.

- Q:Are there any limitations in terms of impact resistance for plastic parts in home appliances?

- Yes, there are limitations in terms of impact resistance for plastic parts in home appliances. While plastic is a versatile material, it is not as strong or impact-resistant as metals. Excessive force or high-impact events can cause plastic parts to crack, break, or become damaged. Manufacturers often utilize engineering techniques and materials to enhance impact resistance, but it is important to handle and use home appliances with care to prevent potential damage to plastic components.

1. Manufacturer Overview |

|

|---|---|

| Location | Hebei, China |

| Year Established | 1991 |

| Annual Output Value | US$ 1 Million - US$ 2.5 Million |

| Main Markets | 40.00% Southeast Asia 15.00% Mid East 10.00% South America 5.00% Southern Europe 5.00% Northern Europe 5.00% Western Europe 5.00% Oceania 5.00% Africa 5.00% Eastern Europe 5.00% North America |

| Company Certifications | ISO 9001:2000; |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | Above 40,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Flexible Anti Static PVC Strip Curtains

- Loading Port:

- TianJin

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 50 Rolls roll

- Supply Capability:

- 15 Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords