Flat or OblateCleaning Ball Making Machine with 6wire3ball

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 50 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications for Scourer making machine

1,short delivery time

2.competitive price

3.good quality

4.manufacture

scourer and scrubber and clean ball machine clean ball making machine clean ball machine stainless steel cleaning ball spiral scourer

This auto cleaning ball knitting machine could produce the steel wire cleaning ball by the principle of squashing, knitting, complete squashing, the knitting process by one time, which is used for stainless steel wire, galvanized wire, copper-plating iron wire, etc., As the clean effect of the products are nice well, it is widely used in hotel, factory, kitchen, bathroom and so on.

We can design other scourer machines specially as customers requirements

Model: | BI-42 | BI-63 | BI-64 |

Brief Structure | 4 wires 2 balls | 6wires3balls | 6wires4balls |

Power | 2.2kW | 2.2kW | 2.2kW |

Voltage | 220V/380V | 220V/380V | 220V/380V |

Productivity | 8 kg/h | 10 kg/h | 12 kg/h |

Packing Size | 1400×800×800mm (L*W*H) | 1500×900×900mm (L*W*H) | 1500×950×950mm (L*W*H) |

Weight | 330KG | 400KG | 500KG |

Volume | 0.9 CBM | 1.3 CBM | 1.45 CBM |

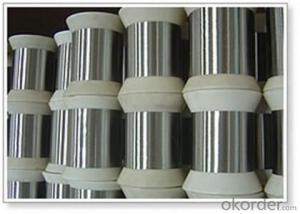

pictures of machine

- Q:How to keep the equipment clean

- It is necessary to set up and carry out the group, to conduct the thorough work, to clean up and clean up. Live things not to be willing to part with or use of production line processing, classify the items in the field use (commonly used, not commonly used to distinguish), is placed in a closet or warehouse not commonly used, commonly used in the scene management of housekeeping;

- Q:The heavy oil on the machine should use what cleaning agent to clean up?

- The downstairs brother was right. I'm the one who often USES this oil cleaner, Because it's local, it's clear that it works well. I recommend you to consult..

- Q:Characteristics of cleaning equipment of cleaning equipment

- High pressure cleaner using high pressure water jet cleaning technology, which is in the 1960 s the rise of a technology, widely used in the removal of incrustation scale proliferation, oil and other hydrocarbons residue coking, also can remove all kinds of coating stab stick coagulation soil lipid layer of gypsum, pigment, rubber, plastic, etc

- Q:Where can I buy cleaning equipment

- Taobao, ali has a lot of, but the preparation factory actually is a few, the basic of taobao is the trafficker... If you haven't done it, try not to buy it, the depth of the device, it's too easy to get into a pit, find a physical store to practice, and see what they're using to buy the best

- Q:What is the pool cleaning equipment

- TR - 300 pool cleaning machine (the queen) : by motor sediment and suspended solids in the suction machine, the water through the filter to filter inside the machine, put the clean water, so as to achieve the cleaning effect. Hd5/11c water gun: applied to the outside of the building, the outside of the building, the external gun, the garage, the floor of the workshop, the kitchen, the vehicle, the pool cleaning, etc.

- Q:What should I consider? To solve the

- Cleaning equipment at present, a lot of international medical devices by using ion exchange, reverse osmosis and ion exchange group legal and reverse osmosis and EDI combination preparation of medical apparatus and instruments clean water, the water treatment equipment manufacturers aimed at the development of medical cleaning equipment market space, are put into research and development industry. According to the process of the preparation of ultra-pure water, there must be an advantage in the development of devices.

- Q:How do you clean the household central air conditioner

- It is mainly the filtration grid that is cleaning outlet, if can ask professional person to clean the wind channel is better

- Q:The main parameters of ultrasonic cleaning equipment

- Ultrasound USES a generator with a high efficiency of 95%, the power of 10 to 100% adjustable 2, and the frequency of high-frequency ultrasonic frequencies, such as 40KHZ, 68KHZ, 132KHZ, etc. Special slow dehydration, circulating hot air drying, replacing traditional solvent dehydration. 4, there is a filter circulation system; Multi-groove ultrasonic cleaning technology;

- Q:How often do the reverse osmosis of pure water equipment wash the search?

- Generally 3 ~ 12 months clean, if every month had to be cleaned once, this explanation should improve the pretreatment system, adjust the running parameter. If you need to clean it once or three months, you will need to improve the operating level of the equipment, and it is difficult to determine if you need to improve the pretreatment system.

- Q:Clean the cleaning parameters of the equipment

- Judge a ultrasonic cleaning machine general technical indicators as to stay ageing degree and resonant, impedance and impedance matching are already debugged before they go out, the key lies in you to do. Of course, the sound of ultrasonic cleaning machine and generator is now being silenced. The bonding mode of the oscillator is usually made of special cement, and the bolt fastening effect is good, but it is not suitable for maintenance. Frequency selection is cleaned according to the workpiece to decide, general material or on the surface is not very high, with 28 KHZ, more strict for cleaning, or had better choose high precision parts. This is because, the lower the frequency of the bubbles, the greater the when ultrasonic frequency is greater than 800 KHZ, there is no cavitation bubbles, this to be the effect of cleaning the surface of the cavitation corrosion is the lowest. In addition, the ultrasonic cleaning is the effect of the high pressure produced by an empty bubble in the instantaneous blast.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Flat or OblateCleaning Ball Making Machine with 6wire3ball

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 50 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products