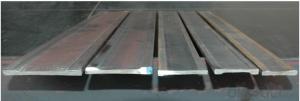

Flat Bar In I Type

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification of Spring Steel:

-Material: 70Si2CrA

-Production: Hot rolled or cold rolled

-Standard: GB/T·5218-1999

-Type: Spring Steel

-Alloy or no: Alloy

Chemical Composition:

C | Mn | Si | Cr |

0.65~0.75 | 0.40~0.60 | 1.40~1.70 | 0.20~0.40 |

S | P | Ni | |

≤0.030 | ≤0.030 | ≤0.030 |

Mechanical Properties:

-Annealing Condition:

1, Tensile Strength: σb/MPa:≤835

2, Elongation: δ/%:≥8

-Quencher condition:

1, Tensile strength: σb/MPa:785~1175

2, Elongation: -

Packaging & Delivery

-Packing Detail: The products can be packed in bundles by steel wires.

-Marks:

1, Tag marks: the tag marks will be tied up to each bundle of the products. The information is usually including supplier’s logo and name, product name, made in China, products’ specifications, the painted color and other information requested by customers.

2, Color marks: we will paint both ends of the bundles of these products to make sure that they are more evident. It’s will be more convenient for the customers to distinguish them at the destination port.

-Delivery Detail:

1, Delivery time: 30~45 working days after receive buyer’s T.T. or L/C.

2, Delivery status should be written in the contract. (Heat treatment or no)

Usage/Applications

Widely used for construction, Machinery manufacturing, Iron tower steel structure, Shipbuilding; Steel grating, Staircase, Bridge, Viaduct, Railway spare parts, Boilers making etc.

Production Flow of Steel Flat Bar

The steel flat bar is made through three processes:

1.Feeding the material: Feeding the row material (the steel plate) to Slitting Line.

2.Slitting:The steel plate would be slitted into expected width by lengthways cutter.

3. Leveled and cutting: The plat bar would be ground into level by the grinder and then cut into required length.

Packaging & Delivery of Steel Flat Bar

Packaging Details: The Steel Flat Bars are packed in bundles and loaded in 20 feet/40 feet container, or shipped by bulk cargo ,also we can do as customer's requirements.

Delivery Details:30~45 days upon the receipt of buyer payment by T.T. or L/C.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: What makes stainless steel stainless?

A3: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

- Q:Can steel flat bars be anodized?

- No, steel flat bars cannot be anodized. Anodizing is a process that is typically used on aluminum or other non-ferrous metals to create a protective oxide layer. Steel, being a ferrous metal, does not undergo the same chemical reaction as aluminum during anodizing, so it is not suitable for this process.

- Q:Can steel flat bars be used for making brackets or supports for security systems?

- Yes, steel flat bars can be used for making brackets or supports for security systems. Steel is a strong and durable material that provides stability and support, making it suitable for constructing brackets and supports to hold security systems in place.

- Q:Can steel flat bars be used in outdoor applications?

- Yes, steel flat bars can be used in outdoor applications. Steel is a highly durable and weather-resistant material, making it suitable for various outdoor environments. Steel flat bars are commonly used in construction, landscaping, and outdoor furniture manufacturing. They can withstand exposure to moisture, sunlight, and extreme temperatures, making them ideal for outdoor applications. Additionally, steel can be treated or coated to provide additional protection against corrosion, further enhancing its longevity when used outdoors.

- Q:What are the standard lengths available for steel flat bars?

- The available lengths for steel flat bars differ based on the manufacturer and customer specifications. Typically, these bars come in lengths ranging from 6 to over 20 feet, with variations based on industry standards or customer preferences. Notably, custom lengths can be obtained by cutting or shearing the steel flat bar to the desired size.

- Q:How are steel flat bars made?

- Steel flat bars are made through a process called hot rolling. The process begins with heating a large rectangular steel billet to extremely high temperatures. The heated billet is then passed through a series of rollers that gradually shape and flatten it into its desired dimensions, typically a rectangular cross-section with a flat top and bottom surface. During the hot rolling process, the billet is compressed between the rollers, which exert immense pressure and force on the steel. This pressure causes the steel to elongate and reduce its thickness, while the width remains constant. As the billet passes through each set of rollers, it is gradually shaped into the desired flat bar profile. To ensure uniformity and precision, the steel bar may undergo multiple passes through the rolling mill, with the rollers adjusted accordingly to achieve the desired thickness and dimensions. Additionally, the steel may be cooled intermittently between passes to control its temperature and improve its mechanical properties. Once the desired dimensions are achieved, the steel flat bar is cut to the required length and then undergoes further processing, such as straightening or surface finishing, if necessary. It is then ready for various applications, including construction, manufacturing, and fabrication. Overall, the hot rolling process is crucial in producing steel flat bars, as it allows for the efficient and cost-effective manufacturing of these versatile and widely used metal products.

- Q:What is the maximum width of a steel flat bar?

- The maximum width of a steel flat bar can vary depending on the specific manufacturing process and the desired application. However, in general, steel flat bars are typically available in widths ranging from 1/8 inch to 12 inches. Some specialty manufacturers may offer wider options as well. It is important to consult with a steel supplier or manufacturer to determine the exact maximum width available for a specific type of steel flat bar.

- Q:What are the different methods of finishing the edges of steel flat bars?

- There are multiple ways to finish the edges of steel flat bars, each with their own advantages and applications. 1. By cutting: One of the simplest methods involves cutting the flat bar's edges to the desired length or shape. Various cutting tools, such as shears, saws, or plasma torches, can be used depending on the steel's thickness and hardness. Cutting results in a clean and precise finish, making it suitable for most applications. 2. Through grinding: Grinding the edges of steel flat bars helps achieve a smooth and polished finish. This process entails using a grinding wheel or belt sander to eliminate any rough edges or burrs, resulting in a clean and professional appearance. Grinding is commonly employed for decorative purposes or when a smooth surface is required. 3. By deburring: Deburring involves removing burrs or sharp edges left after cutting or grinding. This can be done manually using a file or deburring tool, or by utilizing a vibratory or tumbling machine. Deburring ensures safety and enhances the overall appearance of the flat bar. 4. Beveling: Beveling refers to creating angled edges on the flat bar. This is often done to improve weldability or create a chamfered edge for aesthetic purposes. Beveling can be accomplished using specialized tools like beveling machines or by hand with a grinder. 5. Galvanizing: Galvanizing involves coating the steel flat bar with a layer of zinc to protect it from corrosion. This method is commonly used when the flat bar will be exposed to harsh environmental conditions or moisture. Galvanizing not only provides a protective coating but also gives the flat bar a shiny and attractive finish. 6. Powder coating: Powder coating is a technique where a dry powder is applied to the steel flat bar and cured under heat to form a protective and decorative layer. This method offers a wide range of colors and finishes, making it ideal for applications where aesthetics are important, such as furniture or architectural elements. 7. Anodizing: Anodizing is primarily used for aluminum, but it can also be applied to steel flat bars to provide corrosion resistance and improve the surface finish. This process involves creating an oxide layer on the steel's surface through an electrochemical reaction. Anodized steel flat bars are commonly utilized in the construction and automotive industries. In summary, the various methods for finishing the edges of steel flat bars include cutting, grinding, deburring, beveling, galvanizing, powder coating, and anodizing. Each method offers unique benefits and is chosen based on the desired functionality, appearance, and durability required for a specific application.

- Q:What is the standard thickness of a steel flat bar?

- The standard thickness of a steel flat bar can vary depending on the specific dimensions and requirements. However, common standard thicknesses for steel flat bars range from 1/8 inch to 1 inch.

- Q:How do steel flat bars compare to other types of steel profiles?

- Steel flat bars have several advantages over other types of steel profiles. Firstly, their flat shape makes them ideal for use in applications where strength and stability are important, such as in construction and manufacturing. The flat surface also allows for easy attachment and welding, making them versatile and easy to work with. Compared to other steel profiles, such as round bars or square bars, flat bars have a larger surface area, which can contribute to better load distribution. This makes them suitable for applications that require even weight distribution, such as in bridges or platforms. Additionally, steel flat bars have a uniform thickness throughout their length, unlike other profiles that may have varying thicknesses. This uniformity ensures consistent strength and structural integrity, making flat bars reliable and predictable in their performance. Furthermore, steel flat bars are often more cost-effective than other profiles due to their simpler manufacturing process. They can be produced in large quantities and require less machining, resulting in lower production costs. This affordability makes them a popular choice for various industries. However, it is important to note that the choice of steel profile depends on the specific requirements of the application. While steel flat bars offer many advantages, other profiles may be more suitable in certain situations. Factors such as load-bearing capacity, aesthetics, and ease of installation should be considered when determining the most appropriate steel profile for a particular project.

- Q:How do you protect steel flat bars from rusting?

- To protect steel flat bars from rusting, a common method is to apply a protective coating such as paint, varnish, or a rust-resistant primer. Additionally, using a corrosion inhibitor or regularly applying a rust-preventive oil can help safeguard the steel from moisture and oxidation. It's also important to keep the flat bars stored in a dry and well-ventilated area to minimize exposure to moisture.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Flat Bar In I Type

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords