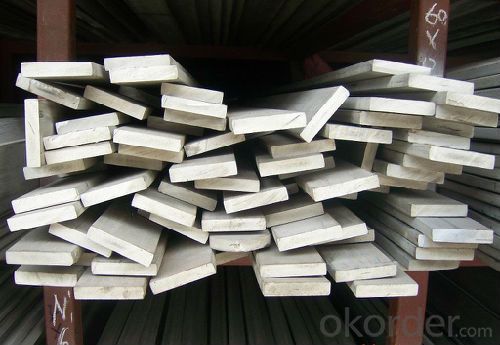

Flat Bar Hot Rolled Q235 High Quality 3MM-30MM Thickness

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering high quality Flat Bar Hot Rolled Q235 High Quality 3MM-30MM Thickness at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc

Product Advantages:

OKorder's Flat Bar Hot Rolled Q235 High Quality 3MM-30MM Thickness are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Sizes: 25mm-250mm | ||||||||||||

a*t | ||||||||||||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 | ||||||||||

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 | ||||||||||

36*3.0-5.0 | 80*5.0-10 | 150*10-20 | ||||||||||

38*2.3-6.0 | 90*7.0-10 | 160*10-16 | ||||||||||

40*3.0-5.0 | 100*6.0-12 | 175*12-15 | ||||||||||

45*4.0-6.0 | 110*8.0-10 | 180*12-18 | ||||||||||

50*4.0-6.0 | 120*6.0-15 | 200*14-25 | ||||||||||

60*4.0-8.0 | 125*8.0-14 | 250*25 | ||||||||||

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

- Q:Can steel flat bars be used for manufacturing conveyor systems or belts?

- Yes, steel flat bars can be used for manufacturing conveyor systems or belts. Steel flat bars are durable and have high tensile strength, making them suitable for heavy-duty applications in conveyor systems. The flat shape of steel bars allows for easy fabrication and attachment of various components required in conveyor systems, such as rollers, pulleys, and support frames. Additionally, steel flat bars can withstand high temperatures, abrasion, and heavy loads, making them a reliable choice for conveyor system manufacturing.

- Q:Are steel flat bars commonly used in the oil and gas industry?

- Yes, steel flat bars are commonly used in the oil and gas industry. These flat bars are widely used for various applications such as building structures, platforms, and equipment used in oil and gas exploration, production, and refining processes. The high strength and durability of steel make it an ideal choice for withstanding the harsh conditions and demanding requirements of the industry. Additionally, steel flat bars can be easily fabricated and welded, allowing for efficient customization and assembly of equipment and structures. Overall, steel flat bars are an essential component in the oil and gas industry, playing a crucial role in ensuring the safety, reliability, and efficiency of operations.

- Q:How do you determine the strength of a steel flat bar?

- The strength of a steel flat bar can be determined through several methods. One of the most common methods is through tensile testing, which involves applying a pulling force on a specimen until it fractures. During this test, the load and deformation are measured, and the stress and strain values are calculated. From these calculations, various mechanical properties such as yield strength, ultimate tensile strength, and elongation can be determined. Another method to determine the strength of a steel flat bar is through hardness testing. Hardness measures the material's resistance to indentation or scratching and is often correlated with its strength. The most commonly used hardness tests for steel include Brinell, Rockwell, and Vickers hardness tests. Additionally, one can determine the strength of a steel flat bar by considering its chemical composition. Steel is an alloy composed primarily of iron and carbon, with other elements such as manganese, chromium, and nickel added to enhance specific properties. The composition and heat treatment of the steel can significantly affect its strength. It is important to note that the bending properties, such as flexural strength, of a steel flat bar can also be analyzed through tests like the three-point bending test or the four-point bending test. These tests determine the maximum load a specimen can withstand before it breaks or yields in bending. In conclusion, the strength of a steel flat bar can be determined through tensile testing, hardness testing, considering its chemical composition, and analyzing its bending properties. These methods provide valuable information about the steel's mechanical properties, allowing engineers and manufacturers to select the appropriate steel grade for specific applications.

- Q:What are the different methods of surface embossing for steel flat bars?

- Steel flat bars can be embossed using various methods. One commonly used technique is roller embossing, where the flat bar is passed between two rollers with a patterned surface. As the bar goes through the rollers, the pattern is imprinted onto its surface, resulting in an embossed design. Another method is press embossing, where the flat bar is positioned between a patterned die and a matching counter die. By applying pressure to the dies, the pattern is pressed into the bar's surface. Laser embossing is a third option, which entails utilizing a laser beam to selectively remove material from the bar's surface in a patterned way. This method allows for the creation of diverse embossed patterns, as the laser can be controlled accordingly. Furthermore, chemical embossing is also available. This involves applying a chemical solution to the bar's surface, which reacts with the metal and forms an embossed pattern. Each method possesses its own set of advantages and disadvantages. The choice of method depends on factors such as the desired pattern, design complexity, and project constraints such as cost and time limitations.

- Q:What are the common methods of surface finishing for steel flat bars?

- The common methods of surface finishing for steel flat bars include grinding, polishing, sandblasting, electroplating, and powder coating.

- Q:Can steel flat bars be easily painted or coated?

- Yes, steel flat bars can be easily painted or coated.

- Q:Can steel flat bars be used for making staircases or ramps?

- Yes, steel flat bars can be used for making staircases or ramps. Steel flat bars are commonly used in construction due to their strength and durability. They can provide a sturdy and stable framework for staircases and ramps, ensuring safety and structural integrity.

- Q:Are steel flat bars suitable for machining operations?

- Yes, steel flat bars are suitable for machining operations. Steel flat bars are commonly used in various machining applications due to their versatility and durability. They can be easily machined using different processes such as cutting, drilling, milling, and turning. The flat surface of the bar provides a stable and consistent material for machining, allowing for precise and accurate operations. Additionally, steel flat bars offer excellent strength and toughness, making them ideal for heavy-duty machining tasks. Overall, steel flat bars are a reliable choice for machining operations in industries such as manufacturing, construction, and automotive.

- Q:Are steel flat bars suitable for architectural cladding?

- Yes, steel flat bars can be suitable for architectural cladding. Steel is a popular material choice for cladding due to its durability, strength, and versatility. Steel flat bars can be used to create sleek and modern designs for architectural cladding applications. They can be easily shaped, cut, and welded to achieve the desired look and can be finished with various surface treatments such as galvanizing, powder coating, or painting to enhance their aesthetic appeal and protect against corrosion. Steel flat bars can be used as vertical or horizontal elements in cladding systems, providing structural support and creating visually appealing facades. Additionally, steel is a sustainable material that can be recycled, making it an environmentally friendly choice for architectural cladding. However, it is important to consider the specific requirements of the project, such as the local climate conditions, maintenance requirements, and the desired design aesthetic, to determine if steel flat bars are the most suitable option for the specific architectural cladding application.

- Q:How do you determine the hardness of a steel flat bar?

- The hardness of a steel flat bar can be determined using various methods, such as the Rockwell hardness test, Brinell hardness test, or Vickers hardness test. These tests involve applying a specific amount of force to the surface of the steel and measuring the depth or size of the resulting indentation. The hardness value obtained from these tests provides an indication of the steel's resistance to indentation and can be used to evaluate its strength and durability.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Flat Bar Hot Rolled Q235 High Quality 3MM-30MM Thickness

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords