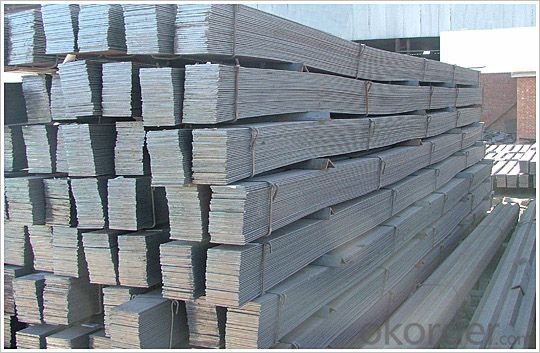

Flat Bar High Quality Steel Flat Bar,Flat Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 24000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Seaworthy export packed |

| Delivery Detail: | 20-25 days |

Specifications

High Quality steel flat bar,flat steel,flat bar

1. Q235,Q345,SS400,ASTM A36,S235JR,S275JR

2. USD 495-516/Ton

3. Free Sample

flat steel,Steel Flat Bar, Galvanized Flat Bar,SS400 flat steel,galvanized flat steel

typical size range: | 10*3 – 300*25mm 6 – 12M Long (special lengths can also be provided) |

Available specifications: | EN 10025 GB/T704-2004 JIS G3101 |

Steel grades: | S235JR, S355JR, Q235B, Q345B, SS400 |

Application of Flat Bar

Flat Bar is used for general fabrication, making structures and frames. Mild Steel Flat Bar can be easily cut and drilled, and is particularly suited to welding. Examples of its use include furniture making, machinery manufacturing, shipbuilding, railway spare parts, iron towers, steel structures, and boilers.

1. What grades and standards of steel are used for your production?

Our grades could meet most of customers demand, such as ASTM, GB, JIS, EN etc…Specific grades include commercial quality, low carbon; high carbon and high strength select low alloys.

2. What type of finishes is your product produced in?

We produce steel product in a wide variety of finishes, including hot-rolled black, hot-rolled pickled & oiled, cold-rolled, aluminized, and hot dipped galvanized. If you have a specific finish that is required, please contact us for additional information.

3. What is your order minimum?

As an experienced steel materials manufacturer, we sell in one full container and combination container. Although the total weight on an order will vary due to the type and size, a typical full container load or less container load order will be approximately 15-25 tons.

4. What could we get if we build up relationship with you company?

Frankly, you get competitive price, good quality materials and considerable payment term. Our experienced team will offer you full service from order confirmation to goods arrival your warehouse. You have nothing to worry about during the process.

- Q:Can steel flat bars be used for tool and die making?

- Yes, steel flat bars can be used for tool and die making. Steel flat bars are commonly used in tool and die making due to their high strength, durability, and versatility. They can be easily machined and shaped into various tooling components such as dies, punches, and molds, making them an ideal material choice for this application.

- Q:What are the load-bearing capacities of steel flat bars?

- The load-bearing capacities of steel flat bars vary depending on various factors such as the dimensions of the bar, the type of steel used, and the specific application. Steel flat bars are commonly used in construction, manufacturing, and structural engineering projects due to their strength and durability. To determine the load-bearing capacity of a steel flat bar, engineers and designers typically refer to industry standards and guidelines such as those provided by the American Institute of Steel Construction (AISC) or the European Committee for Standardization (EN). These standards provide design tables and equations that consider the dimensions of the bar, the steel grade, and the desired safety factors. In general, the load-bearing capacity of a steel flat bar is influenced by its width, thickness, and the distance between supports or points of load application. Wider and thicker bars tend to have higher load-bearing capacities. Additionally, the type of steel used can also affect the load-bearing capacity as different steel grades have varying levels of strength and resilience. It is important to note that load-bearing capacities are typically expressed in terms of maximum allowable loads or uniform load distribution. The specific load-bearing capacity of a steel flat bar can only be determined through proper engineering calculations that consider all relevant factors and safety standards. Therefore, it is recommended to consult with a structural engineer or refer to appropriate industry standards when determining the load-bearing capacities of steel flat bars for a specific application.

- Q:What is the maximum thickness-to-width ratio for steel flat bars?

- The maximum thickness-to-width ratio for steel flat bars can vary depending on the specific grade and type of steel being used. However, in general, the maximum thickness-to-width ratio for steel flat bars is typically around 1:10. This means that the thickness of the bar should not exceed 10 times its width. It is important to note that this ratio may vary based on the specific application and industry standards, so it is always advisable to consult relevant engineering codes and standards to determine the maximum thickness-to-width ratio for a specific steel flat bar.

- Q:What are the applications of steel flat bars in the automotive industry?

- Steel flat bars are extensively utilized in the automotive industry due to their wide range of applications and numerous benefits. Some of the primary uses of steel flat bars in the automotive sector include: 1. Chassis and Frame Components: Automobiles often incorporate steel flat bars in the construction of chassis and frame components. These bars offer the necessary strength and rigidity to support the vehicle's weight and endure various forces and vibrations. 2. Suspension Systems: Suspension systems, including leaf springs and torsion bars, are fabricated using steel flat bars. These components assist in absorbing shocks and vibrations, thereby enhancing the overall ride quality and stability of the vehicle. 3. Braking Systems: Steel flat bars are integral to the construction of various braking system components, such as brake shoes and brake rotors. They provide the essential strength and durability to withstand the high temperatures and pressures associated with braking. 4. Safety Features: Steel flat bars find application in the manufacturing of safety features like roll bars and roll cages. These components offer additional protection to the vehicle's occupants in the event of a rollover or collision, thereby improving overall safety. 5. Bumpers and Grilles: Automobile bumpers and grilles are often fabricated using steel flat bars. These bars provide impact resistance and safeguard the engine and other vital components located at the front and rear ends of the vehicle. 6. Body Panels: Steel flat bars are extensively used in the construction of body panels, such as door frames, roof rails, and window frames. Their strength and stability contribute to maintaining the structural integrity of the vehicle's body. 7. Exhaust Systems: The manufacturing of exhaust systems, including exhaust pipes and mufflers, incorporates steel flat bars. These bars offer high-temperature resistance, corrosion resistance, and durability, ensuring efficient exhaust gas flow and reducing noise levels. In conclusion, steel flat bars play a vital role in the automotive industry by providing strength, durability, and reliability to various components and systems. They significantly contribute to the overall performance, safety, and longevity of automobiles.

- Q:How do steel flat bars compare to cast iron flat bars?

- Steel flat bars and cast iron flat bars differ significantly in their composition, strength, and applications. Regarding composition, steel is primarily an alloy of iron with carbon as the main additive, alongside other elements like manganese, chromium, and nickel, depending on the desired properties. Conversely, cast iron also consists mainly of iron but contains a higher carbon content and silicon. In terms of strength, steel flat bars generally surpass cast iron flat bars in durability. The inclusion of specific alloys during the manufacturing process enhances the strength and hardness of steel. Consequently, steel flat bars can withstand higher loads, making them suitable for applications that necessitate structural support or heavy-duty use. While cast iron retains strength, it is more brittle and prone to breaking under excessive stress. Regarding applications, steel flat bars find extensive usage in construction, manufacturing, and general engineering applications. Their high strength and versatility make them ideal for fabricating machinery, supports, frames, and structures. On the other hand, cast iron flat bars are commonly employed in applications that require resistance to wear, heat, or corrosion, such as machine bases, engine blocks, cookware, and architectural elements like columns and decorative pieces. Considering machinability, steel flat bars are generally more manageable to work with compared to cast iron flat bars. Steel possesses a lower melting point, rendering it more malleable and easier to shape or weld. In contrast, cast iron has a higher melting point and proves more challenging to manipulate. Its brittleness can lead to cracking or fracturing if mishandled during machining processes. Concerning cost, steel flat bars often prove more cost-effective than cast iron flat bars. The manufacturing process for steel is more efficient and less expensive, resulting in a lower cost per unit. Conversely, cast iron necessitates a more intricate manufacturing process, encompassing casting and annealing, which increases its expense. In conclusion, steel flat bars offer superior strength, versatility, and machinability, making them more suitable for applications requiring structural support or heavy-duty use. Cast iron flat bars excel in applications demanding resistance to wear, heat, or corrosion. Ultimately, the choice between the two hinges on the specific requirements of the application, budgetary constraints, and desired properties.

- Q:Are steel flat bars available in different grades of corrosion resistance?

- Yes, steel flat bars are available in different grades of corrosion resistance. Steel is an alloy that can be modified with various elements to enhance its resistance to corrosion. The most common types of corrosion-resistant steel flat bars include stainless steel, weathering steel, and galvanized steel. Stainless steel flat bars are known for their high resistance to corrosion due to the presence of chromium. They are available in different grades such as 304 and 316, each with varying levels of corrosion resistance. These grades are often used in environments where exposure to moisture, chemicals, or high temperatures is common, such as in marine applications, food processing industries, or architectural structures. Weathering steel, also known as corten steel, is another type of corrosion-resistant steel flat bar. It forms a protective layer of rust on its surface, which acts as a barrier against further corrosion. Weathering steel is commonly used in outdoor structures and architectural applications, as it provides a rustic and aesthetically pleasing appearance while offering excellent durability and resistance to atmospheric corrosion. Galvanized steel flat bars are made by coating regular steel with a layer of zinc, which acts as a sacrificial barrier against corrosion. This type of steel is widely used in construction, fencing, and other applications where exposure to moisture and corrosive environments is a concern. In summary, steel flat bars are available in different grades of corrosion resistance, including stainless steel, weathering steel, and galvanized steel. The choice of grade depends on the specific requirements of the application and the level of corrosion resistance needed.

- Q:How do steel flat bars contribute to the overall efficiency of industrial structures?

- Steel flat bars contribute to the overall efficiency of industrial structures in several ways. First and foremost, their durability and strength make them an ideal choice for structural components. Steel flat bars are known for their high tensile strength, which means they can withstand heavy loads and provide structural stability. This strength allows for the construction of taller and more complex industrial structures that can house various equipment and machinery. Furthermore, steel flat bars are highly versatile and can be easily fabricated, cut, and welded to fit specific design requirements. This flexibility enables engineers and architects to create customized industrial structures that maximize space utilization and optimize workflow. Whether used as support beams, braces, or reinforcements, steel flat bars can be tailored to meet the specific needs of a project, reducing construction time and costs. In addition, steel flat bars are resistant to corrosion and can withstand extreme weather conditions, making them suitable for both indoor and outdoor industrial structures. This resistance ensures longevity and reduces the need for frequent maintenance, saving both time and money in the long run. Moreover, steel flat bars are readily available and cost-effective compared to other materials. Their widespread availability and standardized sizes make procurement and construction processes more efficient, resulting in shorter lead times. This accessibility also allows for easy repairs and modifications, ensuring that industrial structures can adapt to changing needs and technologies without significant disruptions. Overall, steel flat bars contribute to the efficiency of industrial structures by providing strength, versatility, durability, and cost-effectiveness. Their usage enhances the structural integrity of buildings, optimizes space utilization, reduces maintenance requirements, and allows for easy customization. As a result, steel flat bars play a crucial role in the construction of efficient and reliable industrial structures.

- Q:How do you determine the load capacity of a steel flat bar?

- To determine the load capacity of a steel flat bar, several factors need to be considered. The load capacity is primarily dependent on the material's strength and dimensions. Here are the steps to determine the load capacity: 1. Identify the steel grade: Different steel grades have varying mechanical properties, such as yield strength and ultimate tensile strength. These properties dictate the load-bearing capabilities of the material. The steel grade is usually specified by the manufacturer or can be determined through material testing. 2. Determine the dimensions: Measure the width, thickness, and length of the steel flat bar. The dimensions directly affect the load capacity. A wider and thicker bar will have a larger load-bearing capacity compared to a narrower and thinner one. 3. Calculate the cross-sectional area: Multiply the width by the thickness of the flat bar to obtain its cross-sectional area (A). This value represents the amount of material that is subjected to the load and is essential for subsequent calculations. 4. Determine the maximum allowable stress: The maximum allowable stress or working stress is a design parameter that depends on the steel grade and the application requirements. It is typically defined in engineering codes or standards. The maximum allowable stress is often expressed in units of force per unit area (e.g., N/mm² or psi). 5. Calculate the load capacity: To calculate the load capacity, multiply the cross-sectional area (A) by the maximum allowable stress (σ). The load capacity (P) can be expressed as P = A * σ. 6. Consider safety factors: In engineering design, safety factors are applied to ensure a margin of safety. The safety factor accounts for uncertainties in material properties, manufacturing processes, and loading conditions. It is common to use safety factors ranging from 1.5 to 4, depending on the level of confidence required. It is important to note that the load capacity calculation assumes that the load is uniformly distributed across the entire length of the flat bar. In real-life scenarios, the load may be concentrated on specific points or areas, in which case additional calculations or design considerations may be necessary. If in doubt, it is always recommended to consult with a structural engineer or refer to relevant design guidelines for accurate load capacity determination.

- Q:What is 40x4 galvanized flat steel, please?

- Refers to the galvanized flat steel, width 12-300mm, thickness 4-60mm, cross section is rectangular and with pure edge of galvanized steel. Galvanized flat steel can be finished steel, also can be galvanized pipe blank and galvanized belt.

- Q:Can steel flat bars be used in fire-resistant structures?

- Yes, steel flat bars can be used in fire-resistant structures. Steel is inherently a fire-resistant material due to its high melting point and low thermal conductivity. In addition to that, steel flat bars are often used in construction for their strength, durability, and versatility. They can be incorporated into fire-resistant structures such as fire-resistant walls, doors, and frames. Steel flat bars can also be used as structural supports and reinforcements in fire-resistant buildings. However, it is important to note that fire-resistant structures require careful design and construction, including the use of appropriate fire-resistant coatings or insulation materials to enhance the overall fire resistance of the building.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Flat Bar High Quality Steel Flat Bar,Flat Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 24000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords