Flame retardant PVC jacket compound for No.5 cable and soft optical cable

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 3000 Tons kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

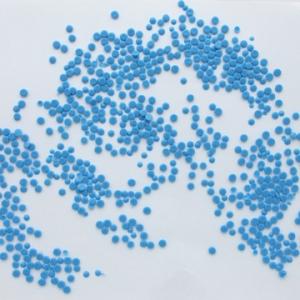

Flame retardant PVC jacket compound for 5#cable and soft optical cable

I. Typeand application

Type | Product | Application and Cable Specification |

2021N | 70℃ Flame retardant PVC jacket compound | Flame retardant PVC jacket compound special for 5# cables |

2023N | 70℃ Flame retardant PVC jacket compound | Flame retardant PVC jacket compound special for 5# cables, CM-class flame retardant |

II. Product description

Flame retardant PVC jacket compound specialfor 5# cables, based on PVC resin, is made into granula by mixing,plastification and granulation with adding plasticizer, stabilizing agent,flame retardant and etc. The products meet various special requirements, suchas different hardness, UV stable, environment friend (RoHs, REACH, PAHs,chlorinated alkanes free, phthalatefree, and etc.), sub-shine and fog surface, low temperature resistant, PS/ABStransfer proof, rodent-repellent, termite-repellent, and transparent, and etc.

III. Processing

Itis recommended that compound should be processed with common extruder having aminimum L/D ratio of 20.

Thefollowing temperature(℃) profileof extruder is recommended:

Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Head | Die |

Temperature ℃ | 145 | 155 | 165 | 175 | 175 | 170 |

IV. Storageand transport

Packaging:25kg/bag, PEmembrane inside bag and Kraft outside bag.

Storage and transport: Avoiding in directsunlight and weathering. The storage place should be in clean, cool, dry, and ventilatedconditions.

V. Properties

Table

Item | Unit | Standard Value | |

2021N | 2023N | ||

Oxygen Index | ≥ | — | 32 |

Tensile Strength | ≥ MPa | 15.0 | 15.0 |

Elongation at Break | ≥ % | 180 | 180 |

Impact Brittleness Temperature | ℃ | -15 | -15 |

Volume Resistivity, at 20℃ | ≥Ω﹒m | 1.0×108 | 1.0×108 |

Dielectric Strength | ≥ MV/m | 18 | 18 |

Thermal Stability Time at 200℃ | ≥ min | 50 | 50 |

Hot Deformation | ≤ % | 50 | 50 |

Thermal Aging |

|

|

|

Aging Temperature | ℃ | 100±2 | 100±2 |

Aging Time | h | 168 | 168 |

Tensile Strength after aging | ≥ MPa | 15.0 | 15.0 |

Variation on Tensile Strength | % | ±20 | ±20 |

Elongation at Break after aging | ≥ % | 180 | 180 |

Variation on Elongation at Break | % | ±20 | ±20 |

Loss of Mass after aging | ≤ g/m2 | 23 | 23 |

- Q:What are the distinguishing features of plastics? What is their chemical name?

- According to the different use characteristics of various plastics, plastics are usually divided into three types: general plastics, engineering plastics and special plastics.

- Q:What material is better for plastic cups?

- 5 is better than PP.The cup has high temperature resistant materials, such as PC, AS, PP.TRITAN, ECOZEN. PC is banned in bottles and some space cups in Europe and america. AS too crisp; PP cost-effective, environmental protection, transparency and feel bad. TRITAN and ECOZEN are currently in the domestic manufacturers do not have the domestic market, export orders, but also environmental protection, does not contain BPA, transparency and feel and equal to PC, the price is high, the daily use of PP can, or glass.

- Q:Do olive nets require any special maintenance during the off-season?

- Yes, olive nets do require some special maintenance during the off-season. It is important to remove and clean the nets to prevent the accumulation of debris and pests. Additionally, inspecting the nets for any damages or tears is crucial, as they should be repaired or replaced if necessary. Proper storage in a dry and protected area is also recommended to ensure their longevity and effectiveness for the next olive harvest.

- Q:How do olive nets prevent olives from being damaged by disease?

- Olive nets prevent olives from being damaged by disease by creating a physical barrier between the olives and external sources of contamination. This helps to reduce the risk of fungal or bacterial infections, as well as the spread of diseases by insects or birds. The nets prevent direct contact of olives with the soil, preventing soil-borne diseases from affecting the fruit. Additionally, the nets provide shade and reduce humidity, creating less favorable conditions for the growth and spread of pathogens.

- Q:How do olive nets prevent olives from being damaged by rodents?

- Olive nets prevent olives from being damaged by rodents by forming a physical barrier that prevents rodents from accessing the trees and reaching the olives. The nets are tightly woven and cover the entire canopy, effectively keeping rodents out and safeguarding the olives from their destructive activities.

- Q:How do olive nets help in harvesting olives?

- Olive nets help in harvesting olives by providing a convenient and efficient way to collect the fallen fruits from the trees. These nets are spread beneath the olive trees to catch the olives as they naturally detach from the branches during the harvesting process. This prevents the olives from falling onto the ground, reducing potential damage and ensuring a higher yield. Additionally, olive nets simplify the collection process, making it easier to gather the olives and transport them for further processing.

- Q:Plastic products 2 can hold hot things?

- We should be inspired, it is best not to take other people's old road, because China is a big country, the harm will be much greater than the United states. It is believed that this problem will gradually arouse people's attention.

- Q:Can olive nets be used in different soil types?

- Yes, olive nets can be used in different soil types. Olive trees can grow in various soil conditions, such as loamy, sandy, or even rocky soils. The nets are primarily used to collect fallen olives during harvest, which is independent of the soil type.

- Q:How do you understand the level of engineering plastics?

- LDPE (low density polyethylene): common plastic film, plastic film and so on. High temperature will produce harmful substances, plastic film into the microwave.

- Q:Can olive nets be used to reduce water stress?

- Yes, olive nets can be used to reduce water stress. Olive nets are commonly used in olive orchards to prevent water loss through evaporation by providing shade and reducing the exposure of the soil to direct sunlight. This helps in conserving water and reducing water stress on the olive trees. Additionally, these nets also help in reducing weed growth, which further minimizes competition for water resources.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Flame retardant PVC jacket compound for No.5 cable and soft optical cable

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 3000 Tons kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords