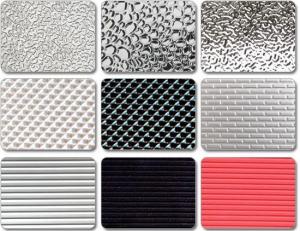

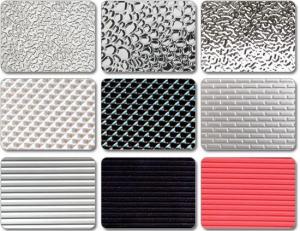

Five Bars, Two Bars, Orange Peel Checkered Aluminum Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Alloy number | 1050 1060 1070 1235 3003 5005 5052 5083 8011 |

Temper | O H14 H16 H18 H22 H24 H26 H32 H112 H114 |

Thickness | 0.2-5mm |

Width | 800-1500mm |

Quality control | ISO 9001 SGS QC |

Application | Working platform, car, cold storage, bottom of boat,workshop anti-skid,decoration material. |

Packing | Seaworthy wooden package |

Payment | 100% irrevocable L/C at sight 30% T/T in advance as deposit and 70% in balance |

Delivery time | 30days after receipt of advance deposit. |

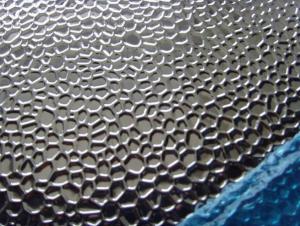

Embossed sheet is also known as checker or diamond plate. The added texture reduces the risk of slipping, making diamond plate a solution for stairs, catwalks, walkways, and ramps in industrial settings. Additional applications include truck beds and trailer floors. Its non-skid properties mean that diamond plate is frequently used on the interior of ambulances and on the footplates of firetrucks.

Utility : decoration industry,anti-slip floor in construction,vehicle, ship,etc.

· Dimensions can be produced according to your specifications

· Very good elongation, anti-corrosion

Packing:Covering with brown paper and plastic bag then packed with wooded plywood then directly loading into container for transshipment

Packaging & Delivery

| Packaging Details: | Yellow paper covering, white foam protecting, standard export package,such as wooden pallet or as required. |

| Delivery Detail: | 15~30 days after receiving your deposit or original L/C |

- Q:Uv decorative plate and aluminum plate What is the difference

- Uv decorative plate is generally in the MDF, plywood and other man-made board surface coated with a layer of UV paint. Aluminum-plastic plate is a thin aluminum plate and plastic together. Uv decorative panels are generally used for indoor products, such as furniture. Aluminum-plastic panels can be used both indoors and outdoors.

- Q:Kitchen and aluminum plate or aluminum plate? What is the difference between the integrated ceiling and the two of them? These three kinds of price?

- Kitchen and toilet are now basically used are aluminum buckle board, aluminum-plastic plate is basically no longer in use, and now most of the integrated ceiling are used aluminum plate, aluminum slab plate its performance than aluminum Plate is good, integrated ceiling than the single plate to calculate the point, the price of aluminum plate about 120 yuan per square or so, about 60 yuan in aluminum, integrated ceiling, then about 8 square to about 1500 yuan, but it contains Design of Artificial River for Electrical Panel.

- Q:How to install aluminum-plastic wall?

- Paste is: the installation of keel --- the installation of the basic board --- with the glue to the aluminum-plastic plate paste in the grass-roots board --- seams hit glass glue --- tear protective film - to complete (note the external wall To waterproof, glass glue if the weathering glue).

- Q:Curtain wall aluminum-plastic plate, Huatian and Huayuan brand how much difference? Including price.

- As well as the finished product testing indicators such as film thickness, peel strength and other production standards,

- Q:Want to buy some aluminum-plastic board, what brand is better?

- Window of the future aluminum-plastic plate,

- Q:Is the aluminum-plastic plate plastic? What is the difference between the two? What are their uses?

- Belong to the same kind of decorative materials. Its advantages are: surface smooth, uniform color, long life, simple construction and so on. Generally used for building facades, store decoration, can also be used for home interior decoration.

- Q:Want to know the building curtain wall, with aluminum veneer materials and aluminum-plastic plate material, what the pros and cons?

- Aluminum alloy veneer - 2 times or 3 times to complete the coating, the coating thickness is generally 30 ~ 40μm. Aluminum-plastic composite panels - one-time roll made, the coating thickness is generally 20μm.

- Q:Facade billboard glass how much money a square about? How much money is a square thanks

- Fifty to one hundred

- Q:Aluminum-plastic composite plate should be set where the edge of ribs

- Side ribs are close to the position of the four folding side, ribs of the material is usually aluminum or zinc square tube,

- Q:Does anyone know that the bathroom cabinet is a solid wood cabinet or a good PVC cabinet?

- Foam pvc cabinet: the basic material does not absorb water, not swollen, no deformation, is a chemical sheet, easy to open materials, products easy to move, in the same kind of bathroom cabinet in the high cost of raw materials. Disadvantage is the material partial soft, poor resilience, fear of high temperature, easy to change color.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Five Bars, Two Bars, Orange Peel Checkered Aluminum Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords