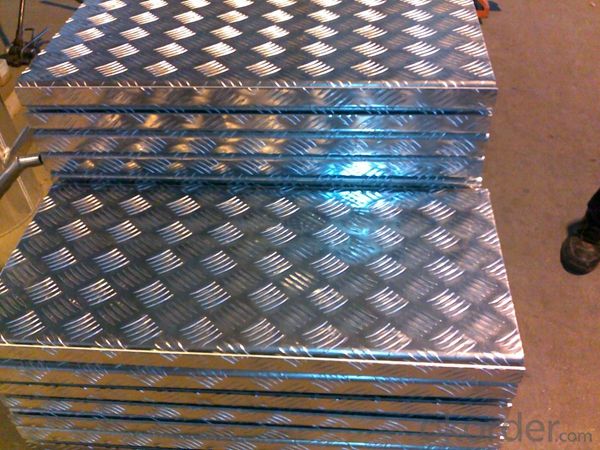

Five Bar Treadplate Aluminium Panel 3003 H14 for Tool Box

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Specification of Five Bar Treadplate Aluminium Panel 3003 H14 for Tool Box

Alloy Number | AA1XXX,AA3XXX,AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

2. Application of Five Bar Treadplate Aluminium Panel 3003 H14 for Tool Box

Transfporation, vehicle, antiskid plate,toolbox,canopy body,

3. Feature of Five Bar Treadplate Aluminium Panel 3003 H14 for Tool Box

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

5. Image of Five Bar Treadplate Aluminium Panel 3003 H14 for Tool Box

6. Package and shipping of Five Bar Treadplate Aluminium Panel 3003 H14 for Tool Box

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:Can aluminum sheets be used for electrical conductors?

- Yes, aluminum sheets can be used for electrical conductors. Aluminum is a good conductor of electricity, although it is not as efficient as copper. However, aluminum is often used in electrical applications due to its lightweight nature, cost-effectiveness, and corrosion resistance. It is commonly used in power distribution lines, wiring systems, and electrical equipment.

- Q:How do aluminum sheets perform in high-temperature environments?

- Aluminum sheets perform well in high-temperature environments due to their excellent thermal conductivity and low melting point. Aluminum has a melting point of 660.3°C (1220.5°F), which is relatively low compared to other metals, allowing it to withstand high temperatures without melting. Additionally, aluminum has a high thermal conductivity, meaning it can effectively transfer heat away from the surface, preventing overheating and maintaining structural integrity. This characteristic makes aluminum sheets suitable for applications in industries such as aerospace, automotive, and construction, where high temperatures are encountered. However, it is important to note that prolonged exposure to extremely high temperatures can cause aluminum to weaken and lose some of its mechanical properties. Therefore, in extremely high-temperature environments, it may be necessary to consider alternative materials or use additional protective measures to ensure optimal performance.

- Q:What are the advantages of using aluminum sheets in the furniture industry?

- There are several advantages of using aluminum sheets in the furniture industry. Firstly, aluminum is lightweight yet strong, making it easier to handle and transport furniture. Secondly, aluminum is resistant to corrosion, ensuring the durability and longevity of furniture products. Additionally, aluminum sheets can be easily molded and shaped into various designs, allowing for creative and unique furniture pieces. Lastly, aluminum is a sustainable material as it is 100% recyclable, making it an environmentally friendly choice for the furniture industry.

- Q:Is aluminum a metal or a non-metal?

- Aluminum is a metal.

- Q:Can aluminum sheets be embossed or textured?

- Yes, aluminum sheets can be embossed or textured using various methods such as roll embossing or mechanical texturing.

- Q:Can aluminum sheets be used for wall cladding?

- Yes, aluminum sheets can be used for wall cladding. Aluminum is a popular choice for cladding due to its lightweight nature, durability, and corrosion resistance. It can be easily shaped and installed, making it a versatile option for various architectural applications, including wall cladding.

- Q:Are aluminum sheets suitable for artistic sculptures?

- Yes, aluminum sheets are suitable for artistic sculptures. Aluminum is a versatile material that can be easily shaped, manipulated, and welded. It is lightweight, durable, and resistant to corrosion, making it ideal for creating intricate and long-lasting sculptures. Additionally, aluminum's natural silver color can add a contemporary and modern aesthetic to the artwork.

- Q:Can aluminum sheets be anodized in different finishes?

- Yes, aluminum sheets can be anodized in different finishes. Anodizing is a process that creates a protective oxide layer on the surface of aluminum, and this layer can be colored or finished in various ways to achieve different aesthetic and functional results.

- Q:How do you cut aluminum sheets?

- There are various methods available for cutting aluminum sheets, depending on their thickness and size. Here, we will discuss some commonly used techniques: 1. Hand shears prove effective for thin aluminum sheets. These handheld tools feature sharp blades that can cut through the sheet by applying manual force. 2. For thicker aluminum sheets, power shears are a better option. These tools, either electric or pneumatic, have powerful blades that can effortlessly cut through the material. They are particularly useful for straight cuts. 3. When it comes to making curved or irregular cuts, a jigsaw with a metal-cutting blade comes in handy. Ensure you use a blade specifically designed for cutting metal. 4. Another method is using a circular saw with a carbide-tipped blade. This technique works well for straight cuts; however, it is crucial to securely clamp the sheet to avoid vibrations during cutting. 5. For precise shapes and sizes, Computer Numerical Control (CNC) machines are ideal. These machines utilize computer programs to control the cutting process, making them suitable for complex or repetitive cuts. Before cutting aluminum sheets, it is essential to prioritize safety. Wear appropriate gear such as gloves and safety glasses to protect yourself from sharp edges or metal shavings. Additionally, secure the sheet firmly in place using clamps or a vise to prevent any movement during cutting.

- Q:Can the aluminum sheets be used for manufacturing chemical reaction vessels?

- Aluminum sheets are indeed capable of being utilized in the production of chemical reaction vessels. The utilization of aluminum, a versatile substance, presents numerous benefits for this particular purpose. Its lightweight nature, durability, and exceptional resistance to corrosion render it suitable for the containment and interaction of various chemicals. Furthermore, the malleability of aluminum enables it to be easily molded and shaped into the desired design for the vessel, granting flexibility in the manufacturing process. Nevertheless, it is crucial to acknowledge that aluminum may not be suitable for all chemical reactions, particularly those involving highly corrosive or reactive substances. In such instances, alternative materials capable of withstanding the specific conditions of the reaction may prove to be more appropriate.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Five Bar Treadplate Aluminium Panel 3003 H14 for Tool Box

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords