Fireproof Calcium Silicate Board for Rotary Kiln

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fireproof Calcium Silicate Board for Rotary kiln Details:

| Place of Origin: | China (Mainland) | Brand Name: | CMAX | Model Number: | |

| Type: | Non-Asbestos Fiber Cement B |

Packaging & Delivery

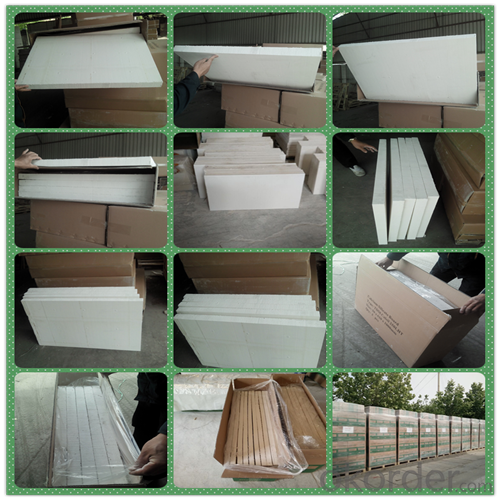

| Packaging Details: | wooden case in LCL, nake package in FCL |

| Delivery Detail: | 15 dyas after receipt of your deposit |

Product Description:

General information for Calcium silicate board:

CMAX calcium silicate products are classified under temperature between 650℃ to 1100℃, it’s an asbestos-free thermal insulation product.

Applications for Fireproof Calcium Silicate Board for Rotary kiln:

◆Reheating furnace

◆Annealing furnace

◆Transfer ladle

◆Rotary kiln

◆Glass tank

◆Shuttle kiln

◆Tunnel kiln

◆Aluminum melting and holding furnace

Main Product Features:

◆Low thermal conductivity

◆High thermal insulation value

◆High strength

◆High strength

Product Specifications:

| Size | Standard Size | 1220*2440*20/22/25mm |

| Appearance | Surface | Surface:Un-sanded |

| Edge | Square | |

| Physical Properties | Density | 1.4-1.6g/cm3 |

| Bending Strength | 16-21Mpa | |

| Moisture Movement | <0.20%< span=""> | |

| Water Absorption | < 20% | |

| Water Contain | <10%< span=""> | |

| Thermal Conductivity | 0.18-0.3 w/(m •k) | |

| Non-combustibility | GB 8624-2006 Grade A1,CE EN 12467:2012 Grade A1 | |

| Water Impermeablility | Traces of moisture appeared on the under surface of the sheet,but no formation of drops of water on the underside of the sheet after 24 hours. | |

| Freeze-thaw | Not have cracking and layering after freeze-thaw cycles 25 times. | |

| Application | 20-25mm thickness is used for Floor & Mezzanine | |

| Average Bearing Loading(Refernce) | 2000kg/m2(distance between 12# Angle Bar is 610*610mm);1200kg/m2(distance between 12# Angle Bar 610*1200mm) | |

| Products Warranty | More than 20 years |

| Raw Material | |

| Cement | Quartz |

| Natural Fiber | Suspension |

| Composition of Finished Product | |

| Crystalloid of Calcium Silicate | Quartz |

| Calcium Carbonate | Cellulose |

FAQ

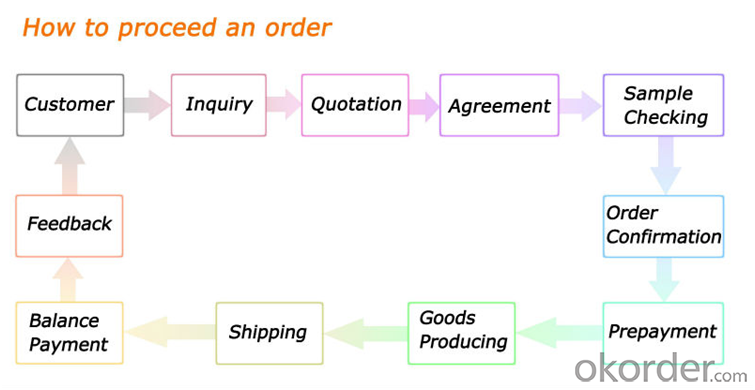

1. How to order ?

2.Can we accept OEM ?

YES! We can according your demand to produce.

3. Can we accept the detective of the third-party verification company ?

YES! We can accept the detective from any third-party verification company including the SGS, D&B and so on.

Our service:

üPrompt reply within 24 hours without delay by our specialized after-sale service sector.

üProvide high temperature solutions and professionals construction services for different fields for our customers.

üProvide the most reasonable logistics for customers to save every penny.

üProduction of goods are finished, thoughtful provide products and packaging photos for our customers.

Welcome to contact me for our Win-Win Cooperation!!!

- Q:What waterproof material moisture in the decoration?

- Gypsum board basically divided into 3 kinds: ordinary paper gypsum board, moisture gypsum board, fire gypsum board; moisture price of the burden of heavy delivery 郛 Hao shop Tong Chung profile; calcium silicate board is not environmentally friendly, there are many shortcomings, I will Inconvenient to say.

- Q:Calcium silicate board does not paint it

- Look at how specific you use, do not brush paint is also possible

- Q:Decoration

- 1220 * 2440 mother 1200 * 600 mother 603 * 603 mother 595 * 595 mother

- Q:Fiber cement pressure plate and calcium silicate board What is the difference, what is the use

- Fiber cement board pressure plate density of 1.5-2.0g / cm3, the density of calcium silicate board does not exceed 1.5g / cm fiber cement board bending strength is V level, silicon calcium board strength is IV level. The performance of the fiberboard must be better than that of the calcium silicate. The same price than silicon calcium plate price is higher

- Q:Silicon calcium board ceiling can be used in home improvement bathroom? why?

- Can not be used in the bathroom must be waterproof moisture-proof silicon calcium board not if there are more problems can click ID consultation

- Q:I do not know that this question is wrong, is a or a set. Want to know a friend told more

- According to the specifications of the price of 40-160 yuan

- Q:It is good to use calcium silicate board or fiber cement board for interior decoration wall

- General wall with calcium silicate board, wall with fiber cement board. Calcium silicate board · Green: no harmful fibers and dust flying, there is no harmful radiation, it can be widely used in a variety of buildings. 1, dimensional stability: the wet sheet and the shrinkage rate of the control in the best range. 2, non-combustible fire: non-combustible A-class material. The main components are inorganic materials, itself is incombustible, the heating temperature of 1000 ℃ or more, the heating time is greater than 1 hour, the wall will not damage, it will not produce toxic smoke. 3, waterproof and moisture: excellent moisture resistance, in the laundry and other high humidity places, can still maintain the stability of the performance, will not expand or deformation. 4, heat insulation: thermal conductivity is very low, a good thermal insulation properties. In the cavity filled with rock wool, 107mm thick wall is equivalent to 1800mm brick wall of the sound insulation, insulation and insulation effect, can greatly enhance the use of building area. 5, light and high strength: light weight, suitable for high-rise buildings and soft ground foundation of the building walls, ceiling. Has a good bending strength, screw pull out force, vertical tensile strength and impact resistance, with it to do the walls and ceiling with reliable ruggedness and durability. 6, the construction is simple: the installation for the dry mode of operation, keel and plate installation and construction of simple and quick. 7, long life: stable performance, acid and alkali, will not be corrosion, it will not be moisture or insects and other damage, and strength and hardness increases with time; can guarantee a long service life.

- Q:My family in the north of the countryside, when the original building, the guest 粻 chicken class Tuen Jiu halo Mo hall with a high 1 meter wide and 50 cm tiles close to the wall around the circle, his wife said it looked good, do not want Yes, but the original is attached to the wall with cement, not easy to get down. I would like to ask, can not use gypsum board or plywood stick to the top, how to get, thank you! More

- Can not, if it is to stick to the tile on the board can also be a lot of tile shop is so on the board, because the back is the embryo body. In front of the glaze is no adsorption force

- Q:Please specify the specific time and the problem, thank you, calcium silicate board is Han Debang, medium density, colorful paint is Pan Cai, imitation stone more

- Due to the density of calcium silicate board is relatively low absorption rate, although the water resistance is also good, even if the bubble in the water 1 month its physical properties are difficult to change, the oil horizon than the main words See is water-based acrylic or silicone C, but also divided into ordinary, shot, high bombs Manufacturers are generally committed to more than 6 years, silicon C can be more than 12 years.

- Q:Calcium silicate is afraid of high temperature

- Not afraid, high temperature materials

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fireproof Calcium Silicate Board for Rotary Kiln

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products