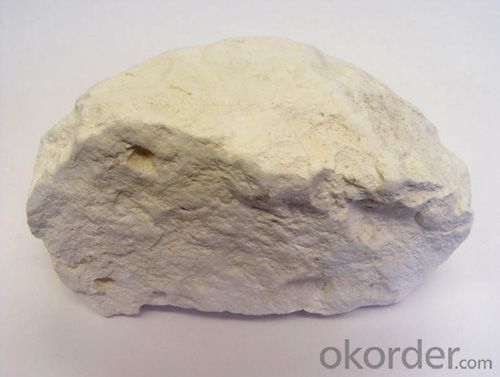

Fireclay refractory mortars

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

粘土质耐火泥浆

项目 | NN-30 | NN-38 | NN-42 | NN-45A | NN-45B | |

耐火度 ℃ 不低于 | 1630 | 1690 | 1710 | 1730 | 1730 | |

Al2O3, % 不小于 | 30 | 38 | 42 | 45 | 15 | |

冷态抗折强度,mpa不小于 C CS min | 110℃干燥后 | 1.0 | 1.0 | 1.0 | 1.0 | 2.0 |

1200℃x3h | 3.0 | 3.0 | 3.0 | 3.0 | 6.0 | |

荷重软化温度2.0% 不低于 |

|

|

|

| 1200 | |

| 1200℃x3h烧后 | 1—-3 |

| |||

1300℃x3h烧后 |

| 1—-5 | ||||

粘结时间 ,min | 1-3 | |||||

粒度 % | -1..0mm | 100 | ||||

0.5mm 不大于 | 2 | |||||

-0.074m 不小于 | 50 | |||||

Note: A is ordinary clay refractory slurry, B for phosphate combined with clay refractory mortar

- Q:Does anyone knows which company produces the better refractory materials?

- A:Building Materials Company of Guangzhou: Near the Baiyun District, Baiyun District, Guangzhou Road, North Road. B:Guangzhou Research & Development Co., ltd.: Liwan District Fengyuan road No.90 in Guangzhou City C: Huitailong decoration materials Co., Ltd.:the 30th floor of No. 111 Pacific Center, Taikang Road, Yuexiu District Guangzhou City D:Guangdong metal materials company: Near Qishan Road, Tianhe District , Guangzhou city.

- Q:How to use fire-resistant soil?

- Clay refractory soil 1, characteristics and uses: Clay refractory brick is a weak acid refractory material, its thermal stability is good, suitable for hot air furnace, all kinds of boiler lining, and flue, smoke room, etc.. 2, product specifications form: standard shape, general, special-shaped and special-shaped brick. Physical and chemical properties of fireclay bricks.

- Q:Which brand of refractory fiber hard thermal insulation board is better?

- Thermal insulation materials are divided into two types: porous material and heat reflecting material. The former uses the air void contained in the material to maintain thermal insulation itself for the heat conductivity coefficient of air or inert gas within the voids is low, such as foam material, fibers and other materials; the latter material has a high coefficient of reflection which can reflect the heat, such as gold, silver, nickel, aluminum foil or metallic coated polyester and polyimide thin films. Aerospace industry has strict requirement for the weight and volume of thermal insulation material, and it is often also required to has the properties of noise absorption, vibration attenuation, and anti-corrosion. Different aircrafts have different requirements for thermal insulation materials. Aircraft cabin and cockpit usually use foam, ultra-fine glass wool, high silica cotton to maintain thermal insulation. Earlier missile head uses phenolic foam plastic as thermal insulating material. With the application of polyurethane foam with good thermal endurance, the single insulating material has been developed to sandwich construction. A few millimeters foaming coating is coated on the skin outside the missile instrument bay, it is anti-corrosion coating at room temperature and when aerodynamic heating reach 200 ° C or more, it will generate foam evenly thus maintaining thermal insulation. Artificial earth satellite moves in an environment where the temperature varies from high to low, so it must use laminated thermal insulation material with high reflecting performance, which is usually made up of dozens of layers of aluminum film, aluminized polyester film, and aluminized polyimide film. In addition, the successful development of the surface thermal insulated tiles has solved the problem of thermal insulation of the space shuttle, it also marks a higher level of development of insulation materials.

- Q:What are included in roof thermal insulation fireproofing material?

- Aluminium foil, bubble, aluminium foil/air bubbles/fireproofing aluminium foil thermal insulation material, fireproofing bubble thermal insulation material, fire?retardant thermal insulation material, thermal insulation construction materials, aluminum foil insulation material.

- Q:What are the construction measures of refractory material in winter? Please descriptive briefly.

- The temperature is low in winter, so refractory bulk materials should be stirred evenly on time to avoid freezing.

- Q:Please answer the questions about the packing and transportation requirements of refractory materials.. Requirements for packing of refractory bricks

- First of all, customer requirements, packaging according to customer requirements. According to the packaging packaging tray packaging is divided into 40 yuan / tons, carton 70 yuan / tons, 40 yuan / ton, straw packing bags of 30 yuan / ton.

- Q:Does anyone know fire-proof material of fireproof wooden door?

- Fireproof wooden door goes through the flame treatment, so it can prevent fire. Its principle: Fire-retardant treated timber has become flame retardant material itself and its fire endurance has increased. The commonly used method of fire retardant treatment for timber including: Spraying method, soaking method, boiling method, vacuum method, vacuum-pressure method.

- Q:Refractory material, refractory brick

- Refractory materials of various varieties, different uses, it is necessary to scientifically classify refractory materials, so as to facilitate scientific research, rational selection and management. There are many classification methods for refractory materials, among which chemical properties classification method, chemical mineral classification method, production technology classification method, material form classification method and so on are included.

- Q:Why should graphitic refractory materials be used now that graphite can burn?

- In theory, any substance can burn as long as certain temperature is reached. Graphite is turned from diamond under anaerobic condition and at high temperature of 2 000 ~ 3 000 ℃. that is to say, ignition point of graphite (lamellar graphite ) under anaerobic condition will be at least above 3 000 ℃. There are many types of graphite, and their ignition points are also different. Ignition point of pyrolytic graphite is much low. Except for a few cutting-edge areas, fire endurance demand for most areas in daily life (eg. brake pad will add a certain amount of graphite) is under 1000 ℃. Therefore, graphite can be used as refractory material. That is, graphite can both burn and can be used as refractory material, which are not contradictory.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fireclay refractory mortars

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords