Fireclay Insulating Bricks for Hot Blast Stove

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fireclay Insulating Bricks for Hot Blast Stove is a kind of insulation material adopting organic matter as ignition loss substance in order to increase the porosity of refractory, which has such advantages as high porosity, small volume density, good insulation effect, high mechanical intensity, small thermal conductivity and long service life. For various industrial kilns & furnaces, it is a kind of essential refractory for energy saving and temperature preservation.

This series of Fireclay Insulating Bricks for Hot Blast Stove are made of selected high alumina bauxite, kaolin clay, hollow microsphere as the mian material.By shaping at high pressure and sintering at high temperature

Product Applications:

1. Furances of glass,coke oven,electric and so on

2.Furnaces of metallurgy industry, heat treatment furnace

3. Furnaces of chemical industry and construction industry.

4. Furnace of incineration of garbage, recirculating fluidized bed furnace

5. Standard sizing: 230 x 114 x 65 or 75 or 25 mm others up to the client

Main Product Features:

1. Low porosity,High bulk density.

2. High Cold Crushing strength.

3. High refractoriness under load.

4. High mechanical strength.

5. Good resistance to erosion.

Product Specifications:

1.With 55% Al2O3 min;

2. Refractoriness: 1750C min;

3.For steelmaking furnaces;

4.ISO 9001 Certificate;

5.Custom shape;

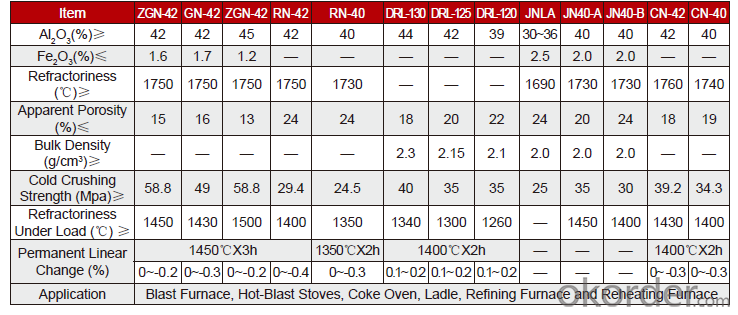

Technical data:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q:what should press on the heat preserving cotton above the suspended ceiling refractory brick ?

- you can also put Z shaped steel on the purline, put heat preserving cotton on the roof boarding, it is easy to oprate.

- Q:How to repair the boiler?

- use refractory bricks and plastic refractory

- Q:does furnace use refractory cement to make refractory bricks?

- You can use fireclay, refractory cement is commonly used to arch. fireclay has good viscidity, it is handy to use.

- Q:Why can't build refractory brick behind the skew block?

- Refractory is heat expansion and cold contraction, when it is high temperature, it will squeeze toward the center and the vault will be deformation .

- Q:Small size black brick can replace refractory bricks for wood burning fireplace?

- No, because the melting point of the black brick is only more than 700 degrees, will flow. But that of refractory brick is above 1200 degrees. It mainly depends on the peak temperature, because the fire area of rural cooking range is small.

- Q:What are required for high temperature refractory bricks?

- good thermal shock resistance:

- Q:Should kiln be warmed before the ignition of the new furnace?

- If you don't have to heat up the furnace. The new furnace must be heated up, and the temperature should be increased according to the heating-up furnace curve, so the current situation you meet is appeared

- Q:How many squares of a ton refractory bricks?

- About 2 tons , general one square clay brick is about 2 tons, from 2, one square corundum brick or magnesia bricks can reach 3 tons, it should say one square is how many tons. if it is high aluminum, then see the content of aluminum. It mainly sees what refractory bricks, because the volume and density of refractory bricks are relatively large.2 tons to 2

- Q:What are the differences and uses of non clay bricks, non clay bricks and ordinary red bricks?

- Just bricks without claySuch as foam hollow bricks, straw bricks, and some other cement bonded solid, hollow bricks and so on

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fireclay Insulating Bricks for Hot Blast Stove

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords