Fireclay Brick with Al2O3 42% for Hot Blast Furnace

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Fireclay Bricks

CMAX fireclay bricks are made from clinker clay. The alumina content ranges from 36% to 48%.

Feature of Fireclay Bricks

Low thermal conductivity

High refractoriness

High mechanical strength

Excellent thermal shock resistance

Application of Fireclay Bricks

CMAX fireclay bricks are commonly applied in blast furnace, hot blast furnace, teeming ladle, glass furnace, etc.

Image of Fireclay Bricks

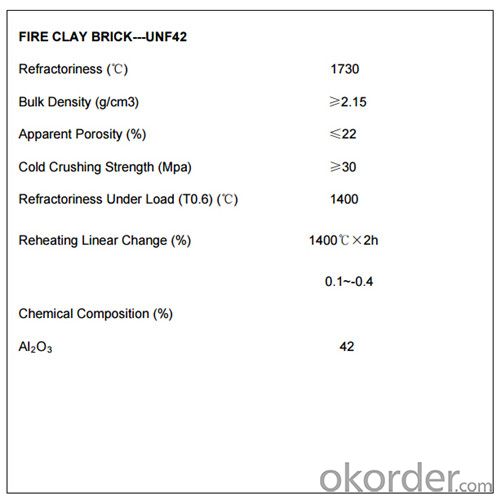

Technical Data of Fireclay Bricks

Why Choose Us

l We are a government owned company with ISO certificate.

l We are listed in Global Fortune 500 with D & B report.

l We have more than 11 refractory production facilities and bases across China. We have a wide products range, such as ceramic fiber products (ceramic fiber blanket, module, board, paper, bulk), ceramic fiber textile (ceramic fiber rope, cloth, tape, yarn) etc, refractory brick (fireclay brick, high alumina brick, silica brick, magnesia brick etc), monolithic refractory materials, insulating fire brick, calcium silicate board, mica sheet, steel fiber. You can find various products here, and we can combine the light weight ceramic fiber products with the heavy weight refractory brick in one container delivery, then save the sea freight for you.

l We have strict materials selecting system and quality control system. We have the ability to take responsibility for your orders and product quality.

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control are conducted by workers and then each piece will be sorted and examined by quality supervis

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks,10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such us U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

Q4: What is the minimum quantity?

A4: There is no minimum order quantity. Depending on the item and processing, there may be a minimum production required, however we can offer a quotation based only on the quantity you need.

Q5: Can you give me a brief introduction of the application of your products?

A5: CNBM (China National Building Material) core refractory business comprises the production, sale and installation of high-grade refractory products, the development and implementation of customized system solutions as well as rendering outstanding services for the key industries in Glass, Iron& Steel, Petrochemical, Cement, Ceramic and Nonferrous Metals.

- Q:Which thermal stability of clay bricks and high alumina bricks is good?

- High alumina brick is made of superfine alumina, fused corundum and fused mullite as main refractory materials. The product has the advantages of high temperature, little creep, strong corrosion resistance and good thermal shock resistance, and is suitable for large and medium-sized hot blast stoves.

- Q:How to make the adhesion between refractory brick and the inner wall of the boiler more firm?

- Professional furnaceman who can weld pins in the boiler steel plate is needed when have the bricklaying, mortar overflowing, connect with the refractory brick

- Q:The foundation is made of Mu10, which is new clay brick and M7.5 cement mortar. What does it mean?

- MU10 is the strength of bricks, and M7.5 is the strength of cement mortar.

- Q:What is the meaning of the new type of dry rotary kiln refractory brick 620,320?

- 20 stands for that the length of the brick is 20CM, there is only a kind of 620 brick for masonry. Simply say: 1. 620 and 320 these two specifications of bricks are needed simultaneously if it is 4 meters kiln that should be built. When the diameter of the kiln is 6M. Other specifications of kiln can be built by useing these two kinds of bricks in different proportions. 3M kiln can be built only by using 320 brick, its proportion of use is 16. 3 stands for kiln's diameter

- Q:What is the color of the refractory brick to repair the same color as the 1400

- Smash the same brick into fine powder

- Q:Is there any special requirements for the building blocks of the smoke and gas wells, how about the refractory bricks?

- There are no special requirements. Not necessarily need refractory bricks, red bricks are ok. The building size of the flue is according to the smoke exhaust rate.

- Q:What are required for high temperature refractory bricks?

- High temperature resistance, high pressure resistance

- Q:Lining of refractory bricks in rotary furnace

- The lining now is built with MgO-C brick, the specific time to change it mainly to see the quality and usage of MgO-C brick. A few years ago, the mills are desperately seeking furnace age, some can use thirty thousand furnace, by the way, furnace age of converter refers to the number of steelmaking furnace not time. So now most mills are not simply pursuit furnace age, but economic furnace age, currently furnace age of steel mills around us is mostly in about ten thousand to twenty thousand. In general, the furnace service of the converter is arranged with the overhaul of other equipment. This can realize the synchronous maintenance of various equipment. If the stove is too old but the maintenance is not timely, also is not to replace the lining brick timely, there will be leakage, then the furnace shell and even ring will be damaged, consequences are more serious . The reason is very simple for brick falling off. One is the poor quality of furnace brick,causing brick lining loose, rocking furnace will lead lining brick falling. the other one is the furnace lining brick is pressed too tight in the use procedure and the brick is too thin.

- Q:Clay brick, red brick, always fried brick how to do?

- Red brick fired, try using a bubble, if not burst, you can use.

- Q:Can porous clay bricks be made of 12 walls to bear weight?

- A porous clay brick, made of 12 walls, does not bear weight. The wall is too thin. The load-bearing wall needs 24 walls at least.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fireclay Brick with Al2O3 42% for Hot Blast Furnace

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords