Fire ResistantC-Strip Aluminum Ceiling Tile

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications:

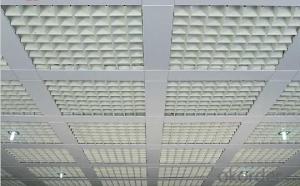

Designed and engineered to perform in multiple commercial environments under multiple stresses,Metal Ceiling systems allow cutting-edge technologies to be applied to the most modern or traditional designs. Every component is designed and fabricated to exacting specifications and the highest manufacturing standards.

Ceiling Type | Size(mm) | Height(mm) | Thickness(mm) | Edge Type |

Clip In Ceiling | 300*300 | 18/20 | 0.45~0.56 | Beveled Edge/Square Edge |

600*600 | 20/24/28 | 0.45~0.7 | Beveled Edge/Square Edge | |

800*800 | 20/24/28 | 1.0 | Beveled Edge/Square Edge | |

300*1200 | 20/24/28 | 0.75~0.9 | Beveled Edge/Square Edge | |

600*1200 | 20/24/28 | 0.75~1.1 | Beveled Edge/Square Edge | |

Lay In Ceiling | 275*275 (295*295) | 8 | 0.60~0.70 | Square Edge |

575*575 (595*595) | 8/12/18 | 0.60~0.70 | Beveled Edge/Square Edge | |

585*585 (595*595) | 10 | 0.60~0.70 | Square Edge | |

585*585(605*605) | 10 | 0.60~0.70 | Square Edge | |

595*1195*575*1175 | 8 | 0.60~0.70 | Square Edge | |

603*1210*585*1195 | 8 | 0.60~0.70 | Square Edge | |

Ceiling Type | Open size(mm) | Width & Height(mm) | Thickness(mm) | Length(mm) |

Open Cell Ceiling | 50*50 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 2000 |

75*75 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 1950 | |

100*100 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 2000 | |

125*125 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 2000 | |

150*150 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 1950 | |

200*200 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 2000 | |

Ceiling Type | Width(mm) | Length(mm) | Thickness(mm) | Edge Type |

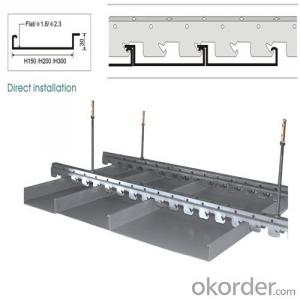

C-strip | C100/C150/C200/C300 | 1000~6000 | 0.45~0.85 | Beveled Edge/Square Edge |

S-strip | C300 | 1000~6000 | 0.45~0.85 | Beveled Edge/Square Edge |

H-strip | C150/C200/C300 | 1000~6000 | 0.45~0.85 | Beveled Edge/Square Edge |

G-strip | C100 | 1000~6000 | 0.45~0.85 | Square Edge |

Installation and Accessories

Clip-in Concealed Metal Panel Ceiling

*Clip-In Panels are constructed of recycled aluminum

*Springs and clips are constructed of high performance steel

*Clip-In Panels integrate into and conceal 15/16” face HD/ID suspension grid

*Clip-In Panels for use in interior application

*Square edge design

*Standard sizes of 24” x 24”, 24” x 48” or custom size

*Clip-In Panels available in solid or perforated designs

*Clip-in placement allows for downward accessibility without special tools

*Easily incorporates air, fire, audio and other services

*Panels contain no organic compounds that support mold or microbial growth

*Factory applied, no-VOC powder coated paints and laminated finishes

The Lay in (I) system is easy to match grid system. The panels are right angle by 8mm chamfer. It's 100% upward accessible and installed on either silhouette grids or other 9/16" (15mm) exposed tee grids, forming unique overall effect. The silhouette grids also can offset manufacturing tolerance and installation tolerance. Also, it can be combined with mineral fiber panels to present a various installation effect.

- Q:I do the aluminum slab plate integrated ceiling, drying rack above the flower drum top should be what glue

- It is best to punch as some durable, with a long time is not very good glue ????? Integrated ceiling is a combination of metal square board and electrical appliances, sub-lighting module, heating module, ventilation module. With the installation is simple, easy maintenance, flexible layout, a bathroom, kitchen ceiling of the mainstream. In order to change the monotonous lack of ceiling color, integrated art ceilings are becoming the market trendy.

- Q:The designer advised us to use the gypsum board on the toilet, said nice, the atmosphere. Because we are in the top floor, does not affect the leakage, we first decoration, good tangled, such as gypsum board, then the cost will be much higher? Please experts to give advice.

- I was decorating, the bathroom ceiling never used gypsum board, the bathroom water vapor weight, gypsum board will suffer after damp

- Q:Under the beam to install aluminum hanging plate ceiling, at least need to stay a few centimeters? (That is, the distance between the aluminum plate and the beam)

- Stay 6 cm on it. Because the aluminum slab board construction from the keel hanging down, there are 6 cm space to buckle down.

- Q:My bathroom in the bathroom on the ceiling of the pipes are leaking, want to remove the aluminum ceiling to see, but how can not open. Will this aluminum bar plate into the ceiling how to disassemble? Thank you!

- The first to use the first toilet to remove the other hand can buckle down

- Q:My home ventilation fans and Yuba buy late, did not catch in front of the ceiling to buy, and now the ceiling master are gone, and some to open the hole, do not know how to do? Asked the ceiling master hole thing, he said very simple, With the United States knife can open their own, so easy to do ?? how can I do !! it is not on their own !! This hole in the end is difficult? Everyone to support the trick! Useful also extra points!

- Scissors will be able to get, the best scissors with scissors

- Q:Kitchen bathroom with aluminum slab plate can do shaped ceiling?

- Strange, kitchen, bathroom area to do the degree of heterosexual ceiling directly to do waterproof gypsum board it, why use aluminum slab plate this material?

- Q:Such as the problem, the wet bathroom will be selected because of the aluminum buckle material and the formation of a layer of water droplets, Is not it should choose the sauna board and other wood materials please answer the other experts and the kitchen and before and after the balcony if you choose the aluminum plate should choose what form, Foil

- Will not drip ah. Not so much water vapor, the balcony can be used gypsum board hanging ah

- Q:What is the difference between a grid ceiling and an aluminum slab plate ceiling? Please all of you

- The main difference, the grille ceiling can see the original roof, and the aluminum buckle plate can not see

- Q:Are there any differences between the ceiling and the Laminates? Is the price the same?

- Aluminum plate is refers to the material, the film is refers to the technical means, two concepts. Aluminum plate, refers to the material is aluminum plate. There are many kinds of technology in the form of aluminum slabs, such as laminating plate, roller coating plate, etching plate and so on.

- Q:Will the bathroom ceiling plate installed on the ceiling (top grade) is not bright, how to change the light bulb? Kouban can be removed, the light can not get down.

- If not, check that the base is not fixed with screws.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fire ResistantC-Strip Aluminum Ceiling Tile

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords