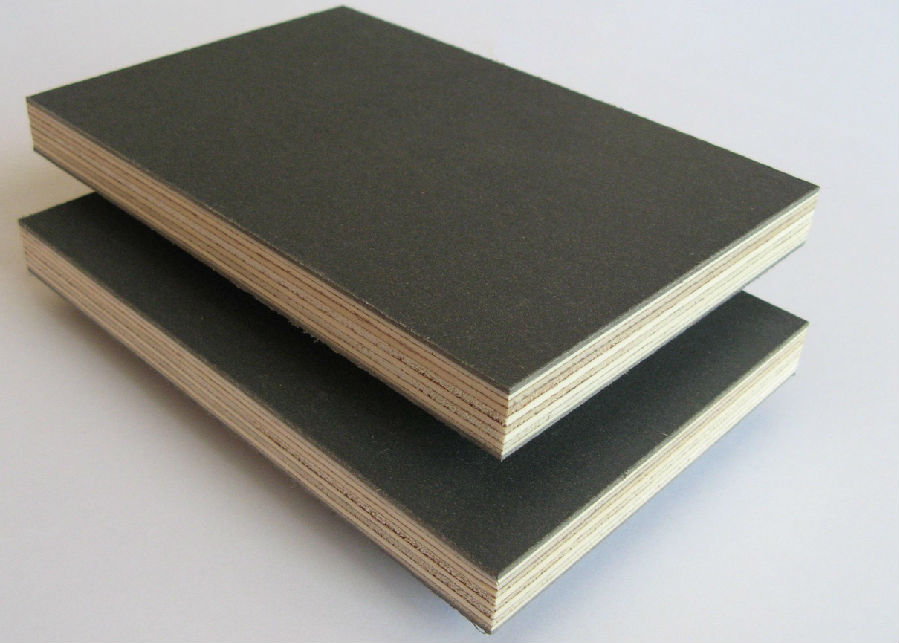

Film Faced Plywood with Top Quality 15MM 18 MM

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 20000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Specification:

Item:film faced plywood

Size:1220x2440mm

Thickness:9mm,12mm,15mm,18mm,20mm,25mm,customer's thickness is available

Color:Brown,Black,Red

Description:

| Product Name | Film Faced Plywood | ||||||||

| Size | 1220x2440mm(4'x8'), 1250x2500mm, 915x1830(3'x6') or as per your requirement | ||||||||

| Thickness | 8-24mm | ||||||||

| Thickness Tolerance | +/-1mm-+/-0.5mm | ||||||||

| Number of Plies | From 5 to 15 depending on thickness | ||||||||

| Face/Back | Black Film, Brown Film, Red Film (Film can be printed with requested logo) | ||||||||

| Finish | Glossy, Matt, Anti-slip | ||||||||

| Core | Poplar, Hardwood, Birch, Combined | ||||||||

| Glue | WBP, Melamine, MR | ||||||||

| Loading Quantity | 50cbm - 58cbm per 40'hq, 45cbm per 40'ft, 22.5cbm per 20'ft | ||||||||

| MOQ | 1X20'ft Container | ||||||||

| Lead Time | 15 days after receiving your prepayment or L/C | ||||||||

| Productivity | 8000cbm per month | ||||||||

| Packing | Inner with waterproof plastic bag, outside with plywood or carton, then fastened with 3'x6' sheet iron and packed with pallets | ||||||||

| Payment terms | TT or L/C at sight | ||||||||

| Production Advantages: | |||||||||

| 1Transference to concrete is set up very easily, so good for construction work. | |||||||||

| 2)Waterproof, Wear-resistant, anti-cracking. | |||||||||

| 3 After installation of concrete, the surface looks like a mirror. (The cement does not stick.) | |||||||||

| 4 It can be used to make camber and it also can be cut into small pieces according the special requirements. | |||||||||

| 5. Environmentally friendly. | |||||||||

| 6 It can be used for a long time, and for the initial price paid for the material, you will feel its worth over time | |||||||||

Features:

1. In boiling water, it can keep glue-sticking and non-deformed for 60 hours at least.

2. Physical mood is better than iron moulds and can satisfy the requirements of

constructing mould ,while the iron ones are easy to be deformed and can hardly

recover its smoothness even after repairing .

3. If used abide by the illustrations strictly. It can be reused more than 50 times.

thus reducing the cost greatly and avoiding the disadvantages from

rusty and erosive of iron mould.

4. Solves the problems of leaking and rough surface during constructing process

5. Particularly suitable for watering concrete project because it can make

the concrete surface smooth and flat

6. Realizing a higher economic profits

FAQ:

1.Can I be your agent?

Yes, welcome to deep cooperation. We have big promotion in the market now. For the details please contact with our overseas manager.

2.Is OEM available?

Yes, OEM is available. We have professional designer to help your brand promotion.

3.Is the sample available?

Yes, samples are available for you to test the quality.

4.Are the products tested before shipping?

Yes, all was qualified before shipping. We test every batch every day.

5.What's your quality guarantee?

We have 100% quality guarantee to customers. We will be responsible for any quality problem.

6.What's benefit will you bring?

Your client satisfied on the quality.

Your client continued orders.

Your can get good reputation from your market and obtain more orders.

- Q:What are the shortcomings of plywood

- the plywood is not as smooth as the density of the board, with the plywood to do the grassroots, the surface and then bonding fire board, aluminum panels and other decorative panels, as the density board to do solid base

- Q:Plywood is a common material for furniture?

- The usual length and width specifications are: 1220 × 2440mm, while the thickness specifications are generally: 3,5,9,12,15,18 mm and so on. The main tree species are: camphor, willow, poplar, eucalyptus and so on.

- Q:Decorative veneer veneer plywood features

- As the product surface of the decorative veneer is made of high quality wood by slicing or peeling processing method, so the plywood has a better decorative performance

- Q:The usual length and width specifications are:

- 1220 × 2440mm, while the thickness specifications are generally: 3,5,9,12,15,18 mm and so on.

- Q:Ordinary plywood is divided into four categories

- According to different density, divided into 80, 70, 60 three categories. Quality level for the premium, one, two three

- Q:What is medium density fiberboard

- Its thickness specifications are 2.7,3,3.5,4,5,5.5,6,7,8 mm, commonly used specifications are 3,3.5,4 mm.

- Q:The basic principle of plywood

- First, symmetry; Second, adjacent layers of single-board fiber perpendicular to each other

- Q:Commonly used plywood, pallets and so on

- Is the destruction of the physical properties of the wood itself, which played a leading role in the composition of the plastic

- Q:How do I determine if plywood contains formaldehyde?

- Those who claim real real wood furniture, which often possession of plywood.

- Q:Why plywood is cheaper than solid wood

- and then made of adhesive glue from the three or more layers of plate-like material, usually with odd-level veneer, and the adjacent layer of veneer Of the fibers are perpendicular to each other

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Film Faced Plywood with Top Quality 15MM 18 MM

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 20000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords