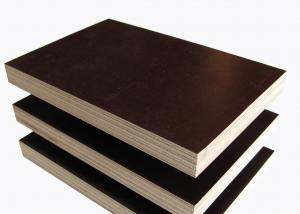

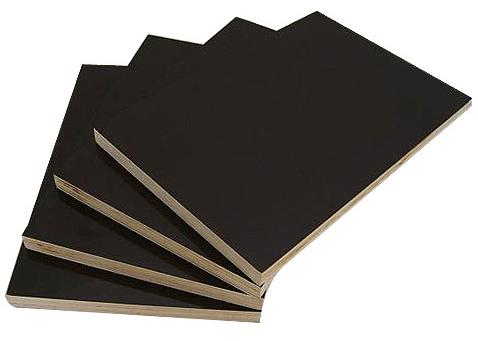

Film faced plywood/Shuttering plywood/Construction plywood/FFP

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Type: | Place of Origin: | ||||

| Model Number: | Usage: | Grade: | |||

| Main Material: | Formaldehyde Emission Standards: | Plywood Type: | |||

| Product name:: | Size:: | thickness:: | |||

| Core: | Glue:: | Face/Back:: | |||

| Application field:: | Boiling time:: | Reuse time:: | |||

| Sample:: |

Packaging & Delivery

| Packaging Detail: | standard export package on pallet |

| Delivery Detail: | Within 15 days after order confirmed |

Specifications

Phenolic bp Brown Film Faced Plywood

2)Dynea glue film hardwood plywood

3)boiled for 20 hours

4)12/15/18m

China Film Faced Plywood Factory /Brown film faced Plywood/phenolic bp film faced plywood

Two times hot press film faced plywood

------------------------------------------

- Q:defects are divided into four grades

- It is generally judged by visualizing the allowable defects on the plywood. The grade depends on the permissible material defects, machining defects, and the requirements for splicing

- Q:How to use building plywood?

- in the decoration works mainly used in ceilings, wall skirts, floor linings and so on.

- Q:Plywood is a common material for furniture?

- The number of layers is generally odd, and few are even. Vertical and horizontal direction of the physical and mechanical properties of small differences.

- Q:What are the types of veneer veneer veneer?

- according to water resistance can be divided into class I decorative veneer veneer plywood, Veneer plywood and class III decorative veneer veneer plywood

- Q:What is medium density fiberboard

- Its thickness specifications are 2.7,3,3.5,4,5,5.5,6,7,8 mm, commonly used specifications are 3,3.5,4 mm.

- Q:The basic principle of plywood

- In order to improve the characteristics of natural wood anisotropy, so that the characteristics of plywood consistent, stable shape, the general plywood in the structure must meet two basic principles

- Q:What are the defects of the plywood?

- unsound section unsound knots The decaying part of a section of a child does not exceed 1/3 of the knot.

- Q:Solid wood and plywood which is better?

- in addition, also need to consider its ground load capacity and use In the geothermal thermal conductivity; and the general splint or plywood in this consideration is not much.

- Q:according to the use of plywood can be divided into needle plywood and broadleaf plywood.

- Ⅲ, Ⅳ plywood moisture content of not more than 15%). ③ quality. Finished products should have rectangular straight edges and obvious edges and corners;

- Q:Now the market prospects for plywood

- so China's plywood enterprises and industry organizations must strengthen communication with importers, strengthen corporate self-discipline

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Film faced plywood/Shuttering plywood/Construction plywood/FFP

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords