FILM FACED PLYWOOD GOOD FOR SALE

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 30000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

FILM FACED PLYWOOD

FILM FACED PLYWOOD

Product Description

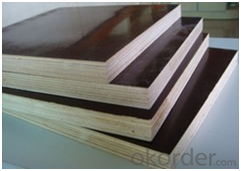

FILM FACED PLYWOOD

(it is a concrete slab use shutteriong plywood, with a smooth or anti-slip, double-sided phenolic overlay film and sealed edges)

Film: Black, Brown, Red

Size: 1220x2440mm(4'x8'), 1250x2500(4.1'x8.2'), 610mmx2440mm(2'x8')

Thickness: 9-21mm

Thickness: Within +-0.3mm-+-0.5mm, can as client's request

Number of Plies: From 9 to 13 depending on thickness and client's request.

Core: Poplar, Hardwood, Birch, Combined

Glue: WBP, Melamine, MR

Surface: Smooth and Anti-slip

| 1220x2440mm,1250x2500mm,610x2440mm | |

Thickness | 9-21mm | |

Tolerance | Length/width :+/-0.2mm; Thickness: +/-0.5mm | |

Core | Poplar,birch,combic,hardwood | |

Min order quantity | 1 set of 40HQ Container | |

Delivery time | 15_20 days upon the receipt of 30% tt deposit or l/c at sight | |

Packaging | Inner plastic bags,outer three-ply or paper-box,wrapped with steel tapes by 4x 6 lines for reinforce | |

quantity | 20GP Container: 8pallets/21M3 | |

40GP Container: 16pallets/42M3 | ||

40HQ Container: 18pallets/53M3 | ||

Usage | making construction formwork plywood, concrete formwork plywood,marine plywood etc | |

Payment | TT or irrevocable L/C at sight | |

Delivery Time | Within 20 days receiving deposit or original L/C at sight |

PHYSICAL TECHNICAL CHARACTERISTICS

1.Moisture content: 6-12

2. Glue shear strength in dry condition: Individual Min 1100Newton, Average Min. 1350 Newton

3. Glue shear strength after wet condition: Individual Min 800Newton, Average Min. 1000 Newton

4. Glue sheear strength in mycological test: Individual Min 800Newton, Average Min. 1000 Newton

5. Tensile Strenght:

A. Parallel to grain direction: Min 325kgf. /cm2

B. Right angle to grain direction: Min 225kgf/cm2

C. Sum of both direction: Min 600 kgf /cm2

6. Modules of Elasticity:

1) Parallel to Grain Direction: Min 8000Neton/mm2

2)Perpendicular to Grain Direction Min 4500 Neton /mm2

PRODUCTS ADVANTAGE

1. Transference to concrete is set up very easily, so good for construction work

2. Waterproof, wear-resistant, anti-cracking

3. After installation of concrete, the surface looks like a mirror. (The cement does not stick)

4. It can be used to make camber and it also can be cut into small pieces according the special requirements.

5. Environmentally friendly

6. It can be used for a long time, and for the initial price paid for the material, you will feel its worth over time

OTHER THINGS YOU MAY CONCERN

1. What 's your MOQ?

Our MOQ is 1*40'HQ or 2*20GP

2. What your your payment term?

By T/T or Irrevocable L/C at sight

3. What's your delivery time?

Usually within 15 days after the down payment, If you need urgent, we can arrange for you first.

4. How about your packing?

We use 0.2mm plastic film inner, all six sides use plywood, then use steel to bundle

5. What's your main products?

Film faced plywood, Commercial Plywood

6. Where is your port?

Qingdao or Lianyungang

WHY YOU CHOOSE US TO BE YOUR SUPPLIER?

1) Quality Products, Excellent Service, Competitive Prices and Prompt Delivery

2) To cooperate with we factory directly instead of pure trade intermediaries can save

Your much more time and cost.

3) We have established a set of strict quality control system, from raw material purchase and the whole manufacturing processes to packing and loading. And nonconforming finished products will be resolutely be replaced.

4) Almost 400 M³ Per day production volume is the most powerful evidence of our strong supply ability. In common, shipment date is within 15 days after receiving down payment.

5) We promise: It is our persistent goal to supply you with sincere and sound services; All orders entrusted to us are given our most careful and prompt attention.

PHYSICAL TECHNICAL CHARACTERISTICS

1.Moisture content: 6-12

2. Glue shear strength in dry condition: Individual Min 1100Newton, Average Min. 1350 Newton

3. Glue shear strength after wet condition: Individual Min 800Newton, Average Min. 1000 Newton

4. Glue sheear strength in mycological test: Individual Min 800Newton, Average Min. 1000 Newton

5. Tensile Strenght:

A. Parallel to grain direction: Min 325kgf. /cm2

B. Right angle to grain direction: Min 225kgf/cm2

C. Sum of both direction: Min 600 kgf /cm2

6. Modules of Elasticity:

1) Parallel to Grain Direction: Min 8000Neton/mm2

2)Perpendicular to Grain Direction Min 4500 Neton /mm2

PRODUCTS ADVANTAGE

1. Transference to concrete is set up very easily, so good for construction work

2. Waterproof, wear-resistant, anti-cracking

3. After installation of concrete, the surface looks like a mirror. (The cement does not stick)

4. It can be used to make camber and it also can be cut into small pieces according the special requirements.

5. Environmentally friendly

6. It can be used for a long time, and for the initial price paid for the material, you will feel its worth over time

OTHER THINGS YOU MAY CONCERN

1. What 's your MOQ?

Our MOQ is 1*40'HQ or 2*20GP

2. What your your payment term?

By T/T or Irrevocable L/C at sight

3. What's your delivery time?

Usually within 15 days after the down payment, If you need urgent, we can arrange for you first.

4. How about your packing?

We use 0.2mm plastic film inner, all six sides use plywood, then use steel to bundle

5. What's your main products?

Film faced plywood, Commercial Plywood

6. Where is your port?

Qingdao or Lianyungang

WHY YOU CHOOSE US TO BE YOUR SUPPLIER?

1) Quality Products, Excellent Service, Competitive Prices and Prompt Delivery

2) To cooperate with we factory directly instead of pure trade intermediaries can save

Your much more time and cost.

3) We have established a set of strict quality control system, from raw material purchase and the whole manufacturing processes to packing and loading. And nonconforming finished products will be resolutely be replaced.

4) Almost 400 M³ Per day production volume is the most powerful evidence of our strong supply ability. In common, shipment date is within 15 days after receiving down payment.

5) We promise: It is our persistent goal to supply you with sincere and sound services; All orders entrusted to us are given our most careful and prompt attention.

- Q:Millennium mill plate is good or the new millennium plate is good

- The new millennium ah ~ Millennium boat operator line brand, the brand with the price on the expensive ah But the new millennium count the second line of the brand, although the fame of thousands of years, but the quality is still very good drops, but also e0 level of eco-eco-board, compared to the price also offers! So for me this ordinary people still feel better than the new millennium!

- Q:Which industries use stainless steel plates

- Building decoration, advertising, medical equipment. General hotel, home decoration, kitchen, plant are used more

- Q:On the difference between Q235 and Q345 plate and use

- Q235 steel is an ordinary carbon structural steel, that the old A3 steel its yield point is 235MPa, tensile strength of 375-500MPa. General use more. Q345 steel is a low-alloy high-strength structural steel, including 16Mn, 12MnV, 14MnNb, 18Nb, 16MnRe, including a class of steel, the yield point of 345MPa, tensile strength of 470-630MPa. Ordinary quality of low alloy steel.

- Q:Is there a sheet with a flame retardant function?

- The market should still have a lot of, after all, now everyone's security awareness are put up. Before the concern of the wood industry's fire-retardant board seems to be doing this, you can see.

- Q:What kind of auxiliary materials / details of the woodworking board shop?

- Main material: 18%: wood core board (woodworking board), paint-free board (ecological board), finger board. Multi-layer board, these are used more often, such as particleboard (melamine board), MDF, etc. 9% of the multi-layer board with more, there are other, such as MDF, Mianqi board with 18% with the direct move 15% direct, multi-layer, MDF, three PCT board is the main panel, there are 5 PCT board

- Q:What kind of domestic brand plate frame good?

- Eyes are their own, love the eyes is very necessary, especially after myopia, do not just say where to see where the glasses discount quickly ran with glasses, but the quality of the glasses off the eye damage is very large , The importance of the frame can not be ignored. So when the glasses with the choice of good glasses glasses is the most critical. Now the glasses are better brands are the island, Daming, the United States pupil - Johnson & Johnson, Hai Chang, snow and so on, these are the brand network MAIGOO 2017 top ten glasses brand, you can go to see the above details. Or that sentence, the eyes are their own, not for a moment of cheap on the casual with the pair of glasses, be sure to choose a good brand.

- Q:The production of melamine sheet

- Melamine decorative board performance: Can be imitation of a variety of patterns, bright color, for a variety of wood-based panels and wood veneer, hardness, wear resistance, good heat resistance. Chemical resistance, and can resist the general acid, alkali, grease and alcohol and other solvent wear. Smooth and smooth surface, easy to maintain cleaning. Because it has a natural wood can not both the excellent performance, it is often used for indoor construction and a variety of furniture, cabinets on the decoration. Melamine board is a wall decoration material. It is not appropriate to use a melamine board counterfeit flooring for floor decoration. Common specifications: 2135mm × 915mm, 2440mm × 915mm, 2440mm × 1220mm, thickness 0.6-1.2mm. In the interior decoration, often used, do light furniture, long life, rapid processing of environmentally friendly! The advantages of this plate is: the surface is flat, because the plate double-sided expansion coefficient of the same and not easy to deformation, bright colors, the surface more wear-resistant, corrosion-resistant, affordable. Domestic production of melamine trim door panels to Lushui River as the representative of the indicators are also reached the international standards. Disadvantages: margin easy to collapse edge, glue traces of the more obvious, less color, can not gong flowers only straight edge.

- Q:Malacca plate true and false how to identify

- On the true and false plate is actually a good identification. For example, the king coconut Malacca E0 class plate, bought a little doubt after his true and false, then you can see his board on the security label, the king coconut plate in the board are anti-counterfeit labels, as long as the scraping Open and can be in the king coconut official website query. In terms of security, the king coconut plate to do is quite good

- Q:How to use a simple method to detect whether it is 316 stainless steel sheet

- You can also use the spectrometer, where you usually buy the goods

- Q:What is cold rolled plate ah? Cold rolled plate is a plate of no

- Cold rolled coil is hot rolled coil as raw material, at room temperature in the recrystallization temperature of the following rolling, including the board and volume, many domestic steel mills such as Baosteel, China Iron and Steel, Anshan Iron and Steel can produce.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

FILM FACED PLYWOOD GOOD FOR SALE

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 30000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords