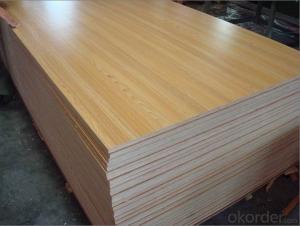

Film Faced Plywood Brown / China & Dubai / Brand: CNBM / COMBI Core / Phenolic / 4'x8'x18mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 57.87

- Supply Capability:

- 6000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Film Faced Plywood is a kind of plywood which inside plywood assembled of veneers and cross band glue impregnated veneers, and outside face veneer on either side topped with glue impregnated film. The glue is used differently like WBP, Phenolic Resin, etc. The veneer made of timber & wood such as Hard Wood, COMBI, Poplar, Birch, etc. Pack in encase in plates and laminated under very high pressure and heat. For the quality two times hot pressure is better than one time hot pressure.

Packaging & Delivery

(1).Packaging Detail: pallets package as standard shipment request.

(2).Delivery Detail: There are two options for customer.

(A).Stock from Jebel Ali Free Zone warehouse in Dubai, delivery available in one day after payment received.

(B).Booking from factories, delivery in 40 days after PI confirmed.

Specifications of Film Faced Plywood (Brand name: CNBM)

(1)Size: 1220 mm×2440 mm, 610 mm×2440mm, other special sizes.

(2)Thickness: 18mm

(3)Core: COMBI, Hard Wood.

(4)Glue: Phenolic

(5)Film: Brown

(6)Pressure: Two time hot press.

(7)Moisture: 6%-9%.

(8)Thickness tolerance: +/-0.2mm.

(9)Duration time: can be 8/9 times used

(10)Usage: For projects requested high quality and specific strength.

(11)Payment term: T/T or L/C at sight.

(12)Manufacture in China and Stock in Dubai,UAE

Advantage of Film Faced Plywood:

(1).Can be used not only one time, profitable as a property.

(2).High strength as wood product.

(3).Stability.

(4).Resilience.

(5).Superior Resistance.

(6).Smooth film faced as mirror.

(7).Flexible. Can be cut from one sheet to smaller specific size pieces.

- Q:How to avoid wood deformation

- At present, many families are in the decoration in the extensive use of wood products, such as curtains, heating hood, fixed furniture, wood lines and doors and windows sets and so on. But once the room temperature and humidity changes, and some wood products will be cracking, warping and deformation and other issues. In fact, many of the quality of home decoration problems are out of the moisture content of wood products. Waterfront blueemption home preferred years Huacheng

- Q:Taobao sell wood products with what packaging is better, what courier is better

- It is not easy to be extruded wood products packaging or iron packaging, things best with foam bags and wrapped film wrapped around. What courier can be. Anyway, have to be thrown to throw.

- Q:Water content is too high or too low, will cause the quality of wood in the home improvement

- multi-application of man-made sheet. Compared with the solid wood materials, a variety of man-made sheet of textured performance to be much more stable

- Q:What is the classification of wood products?

- You in the end is to ask what side, because the use of wood products a lot, so down to the words, to the world chaos,

- Q:Will the small wood products of the dipping (paint) should be how the production process?

- Followed by the primer is closed. After the primer can be dry after the paint.

- Q:American wood products formaldehyde emission standards

- In a letter to EPA, the Sierra Club said that the United States has not yet issued a federal defense to protect the public from the risk of exposure to formaldehyde in furniture, except that the US housing and urban development ministry (HUD) Regulations, it is necessary to develop national standards.

- Q:What are the wood products?

- the most important three points is whether the toxic to the environment, is conducive to recycling. Whether the transition consumes resources.

- Q:How to process woodwork

- Ordinary carpentry lathes can be processed, CNC woodworking lathes can do. Ordinary carpentry can not be processed, CNC woodworking lathe can not do. CNC lathe is only an additional part of the automation, improve the manufacturing accuracy, reduce labor intensity, improve production efficiency. The basic functions are the same: processing a variety of roundabout.

- Q:Who knows the art of wood on the brush is what oil?

- 2, on the role of varnish analysis: Varnish is pigment-free transparent or with a light yellow paint, good gloss, film fast, wide use. The main ingredients are resins and solvents or resins, oils and solvents. [Apply to the surface of the object, the formation of a protective, decorative and special properties of the coating, dry after the formation of smooth film, showing the original pattern of the surface. To Varnish as home decoration in the scene of the construction of the most important lacquer is a unique reason. Polyester paint for the construction environment and construction process requirements are high, and varnish is not. In the process of brushing the flow often occurs in the sagging (tears), for example, polyester paint in the process of forming the sagging process is difficult to re-dissolve solidification, and varnish smoothness is good, there is sagging also It does not matter, then brush it again, sagging can be re-dissolved.

- Q:Processed products (wood products) have to pay any taxes

- Pay the following taxes: 1, VAT 2, urban construction tax 3, education surcharge 4, corporate income tax 5, stamp duty 6, if the processed product is solid wood flooring or a chopsticks have to pay the consumption tax.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Film Faced Plywood Brown / China & Dubai / Brand: CNBM / COMBI Core / Phenolic / 4'x8'x18mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 57.87

- Supply Capability:

- 6000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords