Filament Woven Geotextile in Dykes and Dams

- Loading Port:

- Wenzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 20000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Filament Woven Geotextile in Dykes and Dams

Desciriptions:

PP Woven Geotextile Professioal Waterproof Geotextiles. A woven geotextiles is an economical solution for any civil engineering applications. It separates, stabilizes, and reinforces soils and allos allows for filtration. Woven geotextiles are manufactured by extruding polypropylene film and then slitting the film into individual yarns which are then woven to form the geotextiles.

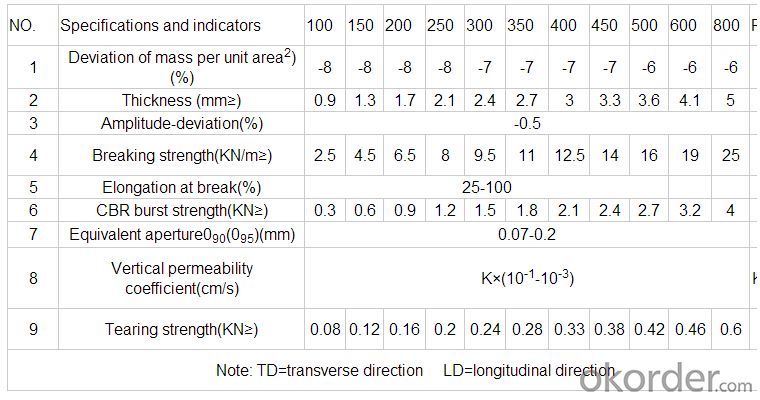

Specifications and Technical datas:

| Weight / Mass | 100gsm - 800gsm |

| width | Within 8 m |

| longth | 50-100m/roll (at request) |

| Material | PP / PET |

| Color | Black , white , grey |

| Certification | CE/ISO9001 |

| Manufacturing method | nonwoven / woven |

Characteristics:

Easy process and high output rates

Excellent distribution of carbon black

Consistent quality and low failure rate

Excellent resistance and good waterproof ability

Good welding

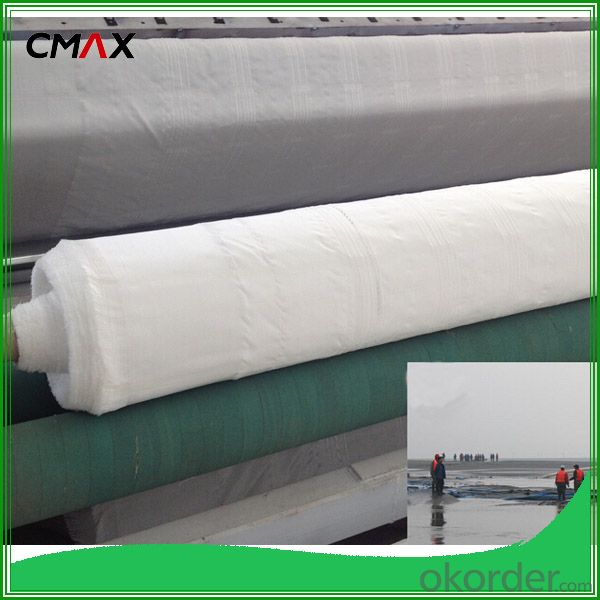

Details of our products:

Produce process:

Applications:

1) Filtration :

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

2) Separation :

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

3) Adding muscle :

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earth body stability.

4) Protection :

It prevents the bank from being washed out, protects the bank and the bottom, prevents the water and soil from being washed away.

Packing and shipping:

1. The outer package: black or white woven geotextile.or we can make the package as your requst.

2. Different tgram/ roll size for different qty in the same containers.

3. Roll size: 3.95m*200 for container

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

HDPE Geomembrane Price

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q:Are geotextiles commonly used in canal lining applications?

- Yes, geotextiles are commonly used in canal lining applications. Geotextiles provide excellent erosion control and filtration properties, making them an effective solution for preventing soil erosion and maintaining the integrity of canal linings.

- Q:How do geotextiles help with load transfer in foundation systems?

- Geotextiles help with load transfer in foundation systems by providing a stable and uniform platform for distributing the load from the structure to the underlying soil. They act as a separator, preventing the mixing of different soil layers and reducing the risk of differential settlement. The geotextiles also enhance the soil's strength and stability, thereby improving the overall load-bearing capacity of the foundation system.

- Q:Geotextile standard is broken how low?

- You can not do it

- Q:How are geotextiles tested for quality assurance?

- Geotextiles are tested for quality assurance through a series of standardized tests that evaluate their physical, mechanical, and hydraulic properties. These tests may include assessing tensile strength, elongation, puncture resistance, water permeability, and filtration efficiency, among others. By conducting these tests, manufacturers can ensure that geotextiles meet the required performance specifications and provide consistent quality for various civil engineering applications.

- Q:What are the key properties to consider when evaluating geotextiles?

- When evaluating geotextiles, some key properties to consider include the strength and durability of the material, its filtration and drainage capabilities, its resistance to UV degradation and chemical exposure, as well as its permeability and compatibility with the intended application. Additionally, factors like cost-effectiveness, ease of installation and maintenance, and environmental sustainability should also be taken into account.

- Q:Manufacture of geotextile machinery

- Non-woven needle machine, I am specializing in the production of geotextiles

- Q:Geotextile universal testing machine with 20kn enough?

- Conventional geotextile mechanics test using 20KN test machine on it, individual users need to do some large range of mechanical tests, our company also has some customers choose 50KN universal testing machine. The specific choice of 20KN or 50KN to see if you are on the equipment requirements upwards compatible.

- Q:What are the different installation methods for geotextiles?

- There are several installation methods for geotextiles depending on the specific application and project requirements. Some common methods include loose-laid, anchored, and mechanically stabilized installation. In the loose-laid method, the geotextile is simply placed on the ground surface without any additional fixation. Anchored installation involves securing the geotextile to the ground using stakes, pins, or other fasteners. Mechanically stabilized installation utilizes heavy machinery or equipment to mechanically compact the geotextile into the ground. The choice of installation method depends on factors such as soil conditions, project specifications, and desired performance outcomes.

- Q:What are the different geotextile installation techniques in erosion control?

- There are several geotextile installation techniques used in erosion control, including trench installation, slope installation, and blanket installation. Trench installation involves placing geotextile fabric in a trench along the slope to prevent soil erosion. Slope installation involves placing geotextile fabric on the surface of a slope to stabilize the soil and prevent erosion. Blanket installation involves placing geotextile fabric over a large area, such as a construction site or a riverbank, to provide erosion control and sediment filtration. Each technique has its own advantages and is chosen based on the specific erosion control needs of the site.

- Q:What are the key factors affecting the permeability of geotextiles?

- The key factors affecting the permeability of geotextiles include the type and thickness of the geotextile, the size and distribution of the pores, the type of soil or material being filtered, the compaction of the soil, and the hydraulic gradient or pressure difference across the geotextile.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Filament Woven Geotextile in Dykes and Dams

- Loading Port:

- Wenzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 roll

- Supply Capability:

- 20000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords