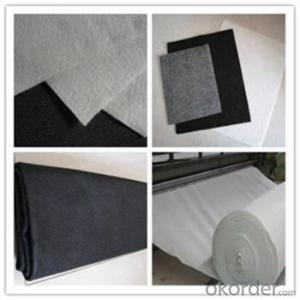

Filament Spunbond Nonwoven Geotextiles Building Material Geotextile Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q:Can geotextiles be used in the construction of sports fields?

- Yes, geotextiles can be used in the construction of sports fields. Geotextiles are commonly used as a base material to provide stability, drainage, and erosion control in various construction projects, including sports fields. They help to prevent soil movement, promote proper drainage, and enhance the longevity and performance of the field.

- Q:Are geotextiles effective in preventing weed growth?

- Yes, geotextiles are effective in preventing weed growth. They act as a physical barrier that inhibits weed growth by blocking sunlight and preventing weed seeds from germinating. Additionally, geotextiles allow for water and air permeability, ensuring proper drainage while still suppressing weed growth.

- Q:How do geotextiles help with moisture management in construction projects?

- Geotextiles aid in moisture management in construction projects by acting as a barrier against water infiltration and promoting drainage. They are permeable fabrics that allow water to flow through, preventing water buildup and potential damage to structures. Geotextiles also help to stabilize soil, control erosion, and separate different soil layers, further enhancing moisture management in construction projects.

- Q:Consult geotextile and geomembrane is not the same thing?

- Geomembrane completely soiled geotextile is to keep the wet state of water will evaporate

- Q:What are the applications of geotextiles in road construction?

- Geotextiles have numerous applications in road construction, primarily in the areas of soil stabilization, drainage, and erosion control. They are used as a separation layer between the subgrade and the base course to prevent the mixing of different soil layers, thereby enhancing the stability and longevity of the road. Geotextiles also aid in improving the drainage system by allowing water to flow through the fabric while preventing soil particles from clogging the drainage system. Furthermore, they are employed to control erosion by preventing soil erosion from embankments and slopes, thereby maintaining the integrity of the road structure. Overall, geotextiles play a crucial role in enhancing the performance and durability of roads.

- Q:Road geotextile about how much money

- Geotextiles are generally in the width of 1 to 8 meters, between the weight of 100g ~ 1000g. There is the standard of the national standard Prices are based on specifications.

- Q:Where to find the right geotextile

- Geotextile types are many, according to the manufacturing process of spinning, woven, woven, according to the material is divided into filaments, short wire and so on, if the most suitable geotextile should be the project requirements are not very strict , Generally like building coverage, road maintenance, etc., like this price is generally around 0.5 angle

- Q:Where is the geotextile in the municipal works?

- Conservation, consideration, there is more green and more Chinese geotextile material manufacturers

- Q:The outside of the blind tube is not to be with the geotextile 1 effect will be better?

- Plastic blind ditch is a new geosynthetics, is composed of plastic core wrapped outside the filter composition. At present the plastic core has several different cross-sectional shape rectangular, hollow rectangular, circular and hollow circular species structure of the plastic blind ditch products. Pass the water to see the original tie & gt; & gt;

- Q:Geotextile with the welding tool where to buy

- I am the manufacturer

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Filament Spunbond Nonwoven Geotextiles Building Material Geotextile Fabric

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords