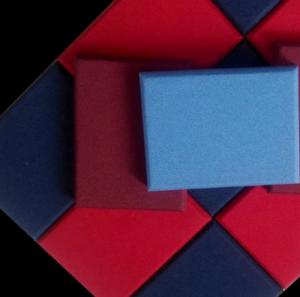

Fiberglass Wall Panel with Fabric HC-382

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications:

Main Material: Fiberglass wool

Density: Standard 100kgs/m3

Thickness: 25mm, 40mm, 75mm and etc.

Size: Standard 1200*600mm, max 2700*1200mm and etc.

Surface: Decorative or Fiberglass Fabrics in different colors

Edge: Square, Bevel

Quick Detail:

Non-combustible;

No sagging, warpping or delaminating;

Green building material;

Excellent sound absorption;

With different pattern available;

Applications:

Halls, Classrooms, Offices, Shopping centers, etc.

Competitive Advantages:

Fire-resistant;

Thermal-insulation;

Humidity-resistant;

Cleanability;

Environmental;

Elegant;

Safety and Convenience;

- Q:The difference between GRC lightweight partition board and ceramic plate

- A plate made of ceramsite concrete, usually a non - load - bearing wallboard.

- Q:What is GRC and can I paint it?

- GRC popular understanding of it, refers to the FRP to do the components of profiles. Can be made into any shape, such as sculpture, murals, decorative lines, etc., generally have a good finished product for you to choose. The advantage is high hardness and light weight and the price is not expensive. Is now a large number of decorative materials used. Can be based on your request, do oily or metallic paint, using the basic are spraying process. Another: custom need to open a separate mold costs, so if a small amount of custom, it is more expensive friends.

- Q:Inorganic fiberglass contrast color steel composite board which is good? Requirements insulation good! preservative! Thank you

- Fiberglass is a glass fiber reinforced plastic commonly known as it is a glass fiber reinforced material, synthetic resin as the base material of the composite products. FRP has a good anti-corrosion properties. Especially the water and dilute the concentration of acid Liquid, and can show its superiority, and FRP lightweight high strength specific gravity of 1.7-1.8 is a quarter of steel.For the insulation: you can use polyurethane foam. With light weight. High strength. Low thermal conductivity. Non-absorbent and other characteristics. Has been widely used in travel. Building. Cold storage. Refrigerator. Petrochemical. Indoor air conditioning.

- Q:Is the interior wall made of fiberglass mesh good or wire mesh?

- If only the local cracks, you can also use ordinary straps paste.

- Q:Glass fiber mesh quality soft and hard for the wall, which is better?

- The general wall of the grid with a fast money about 1 square meters on the good. Tengda grid cloth 8 hair can also be used. Selling is also good,

- Q:What are the lightweight wallboard materials?

- Light wall material as a new type of product, technology is still in the process of the evening, this period inevitably there are some quality problems, affecting its promotion. In the long run, due to the wall material has embarked on a thin body, light, functional diversification (insulation, sound insulation) of the road of innovation, light wall panels will be developed as the country, as a wall material leading.

- Q:What is the difference between GRC reinforced concrete slabs and lightweight aggregate concrete partitions?

- GRC reinforced concrete slabs and lightweight aggregate concrete partitions are lightweight wall panels that can be used to make walls. Should be selected materials and processing methods are not the same

- Q:FRP can be used to make walls

- If the use of fiberglass do wall to see and what it is connected to the medium, or very easy to stratify, if it is in the cement surface to do the wall, I suggest you use epoxy resin, resin and sub-reinforced resin and food Grade resin, with food grade resin to do, no harm to the body, that is not food-grade, after curing the harm to the human body than other decorative materials damage small

- Q:Wall material that kind of environmental protection?

- Now environmentally friendly materials are relatively more latex paint and wall cloth are good, but the use of life is limited, weak base of diatom mud to do not only environmental protection can also be used for more than 20 years, is now popular new materials.

- Q:What is the quality of the light barrier now?

- 1. Thermal insulation performance: insulation than the thickness of 570mm brick wall, can greatly reduce the cooling and heating and other electricity, burning costs, can be described as the best choice for energy conservation. 2. Construction speed: easy to install, more than 8 times faster than the concrete pouring method; wall panels can be sawed, can be nailed, drillable, can be arbitrarily cut, free manufacturing structure. 3. Soundproof and waterproof fire performance: sound insulation up to 45dB, the plate has a self-waterproof function, fire resistance of 2.5 hours or more. Anti-freeze-thaw cycle more than 25 times, moisture-proof performance testing projects have reached the national standard.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass Wall Panel with Fabric HC-382

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords