Fiberglass Unidirectional fabric 227gsm 1000mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Process

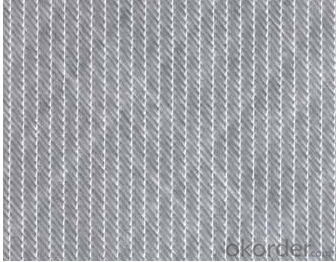

Fiberglass unidirectional fabric is the product combining the roving in certain angel of 0 ℃ or 90 ℃ with polyester yarn.

Properties

• Fiber straight arranged, fiber strength be ultimately used.

• No powder or emulsion, sink quickly, easy to operate.

• Easy to design, high strength in one direction.

Applications

Mainly be used as reinforced materials in the composite material industry.

• Matrix: unsaturated polyester resin, vinyl ester resin, epoxy resin and phenolic resin etc.

• Craft: winding, pultrusion, hand lay up, etc.

• Ultimate products: storage tank, tube, pultruded profiles, FRP body of boat, etc.

Specifications

specifications

Fibre type

0°Roving

90°Roving

Overall weight

Width

(g/㎡)

(g/㎡)

(g/㎡)

(mm)

EDW227

E-Glass

—

227

227

1524

EDW350

E-Glass

—

350

350

1524

EDW450

E-Glass

—

450

450

1524

EDJ600

E-Glass

480

120

600

1524

EDJ800

E-Glass

600

200

800

1524

EDJ1000

E-Glass

600

400

1000

1524

Packaging: Wrapped in PVC and placed within a cardboard carton.

FAQ of Woven roving combo mat:

Mainly be used as reinforced materials in the composite material industry.

• Matrix: unsaturated polyester resin, vinyl ester resin, epoxy resin and phenolic resin etc.

• Craft: pultrusion, RTM, hand lay up, etc.

• Ultimate products: pultruded profiles, FRP body of boat, insulation board, automobile body.

Delivery Detail: 15-21days

Other spec. can be custom made as per customer's request.

- Q:Can fiberglass mat tissue be used for making surfboards?

- Surfboards can indeed be made using fiberglass mat tissue. This material, known for its lightweight yet robust properties, is commonly utilized in constructing surfboards. Typically, it is combined with epoxy resin to form a sturdy and durable surface. By incorporating fiberglass mat tissue, surfboards gain the strength and flexibility necessary to endure the demanding conditions encountered while riding waves. Moreover, the smooth and sleek texture of the material enhances the surfboard's performance and speed. In summary, fiberglass mat tissue is a favored option for constructing high-performance surfboards due to its exceptional strength-to-weight ratio.

- Q:What is the impact resistance of fiberglass mat tissue?

- The impact resistance of fiberglass mat tissue is quite high due to its inherent properties and construction. Fiberglass mat tissue is composed of fine glass fibers that are randomly arranged and bonded together with a binder material. This arrangement creates a strong and flexible mat that can withstand impacts and external forces. The random orientation of the glass fibers allows for the distribution of stress and energy across the entire mat tissue. When an impact is applied, the fibers absorb and disperse the force, preventing it from being concentrated in one area. This property helps to minimize the risk of cracks, fractures, or failures in the material. Additionally, the binder material used in fiberglass mat tissue provides further reinforcement and cohesion to the structure. It acts as a bonding agent, keeping the glass fibers in place and enhancing their overall strength. This bonding ensures that the mat tissue remains intact and resilient even under high impact loads. Due to its excellent impact resistance, fiberglass mat tissue is commonly used in various applications where durability and strength are essential. It is often utilized in the manufacturing of composite materials, such as fiberglass-reinforced plastics (FRP), to enhance their impact resistance and structural integrity. It is also frequently employed in the construction industry for applications like roofing, wall insulation, and soundproofing, where it provides protection against impacts and external forces. Overall, the impact resistance of fiberglass mat tissue is a key characteristic that contributes to its widespread use in numerous industries. Its ability to withstand impacts and distribute forces makes it a reliable material for applications that require strength, durability, and protection against external forces.

- Q:Can fiberglass mat tissue be used as a reinforcement in concrete?

- Indeed, fiberglass mat tissue is a feasible option for reinforcing concrete. Composed of fine, lightweight material woven from fiberglass strands, this material is widely used in construction and industrial settings due to its exceptional strength and durability. By incorporating fiberglass mat tissue as reinforcement in concrete, the tensile strength and resistance to cracks can be significantly improved. Typically, it is applied in the form of a mesh or fabric, which is embedded within the concrete during its pouring phase. The presence of fiberglass strands in the mat tissue adds extra strength and reinforcement to the concrete, thereby reducing the likelihood of cracks and enhancing the overall structural integrity. This feature proves especially advantageous in areas where the concrete is subjected to heavy loads, such as bridges, concrete slabs, or precast concrete elements. Furthermore, fiberglass mat tissue possesses corrosion-resistant properties, which renders it a suitable choice in scenarios where the concrete comes into contact with moisture or chemicals. Unlike traditional steel reinforcement, it does not rust or deteriorate over time, thereby extending the lifespan of the concrete structure. To summarize, fiberglass mat tissue serves as a practical and efficient solution for reinforcing concrete. It offers improved strength, crack resistance, and corrosion resistance, making it a favored choice in various construction projects.

- Q:What is the specific gravity of fiberglass mat tissue?

- The specific gravity of fiberglass mat tissue can vary depending on the specific composition and manufacturing process. However, generally speaking, fiberglass mat tissue typically has a specific gravity ranging from 1.8 to 2.2. Specific gravity is a measurement that compares the density of a substance to the density of a reference substance, usually water. A specific gravity of 1.0 indicates that the substance has the same density as water, while a value greater than 1.0 indicates a higher density. Therefore, the specific gravity of fiberglass mat tissue suggests that it is denser than water.

- Q:Is fiberglass mat tissue compatible with different resin systems?

- Fiberglass mat tissue is indeed compatible with different resin systems. This versatile material can be utilized with a variety of resin systems, such as polyester, epoxy, and vinyl ester resins. Its exceptional wet-out properties enable the resin to be absorbed and distributed evenly throughout the mat. Consequently, this compatibility facilitates the fabrication of robust and long-lasting composite structures for numerous industries, including automotive, marine, construction, and aerospace. Nevertheless, it is crucial to carefully assess the unique properties and characteristics of the resin system employed to guarantee optimal performance and compatibility with the fiberglass mat tissue.

- Q:What is the chemical resistance of fiberglass mat tissue?

- Fiberglass mat tissue exhibits excellent chemical resistance due to the inherent properties of the fiberglass material. The mat tissue is typically composed of glass fibers that are woven or bound together, providing a barrier against a wide range of chemicals. The glass fibers themselves are highly resistant to corrosion, making fiberglass mat tissue suitable for use in environments where exposure to chemicals is a concern. The chemical resistance of fiberglass mat tissue can vary depending on the specific resin or binder used in the manufacturing process. Different types of resins may provide enhanced resistance to certain chemicals, while others may be more susceptible to degradation. It is important to consider the specific chemicals that will come into contact with the fiberglass mat tissue and select a resin or binder that is compatible with those substances. In general, fiberglass mat tissue is known for its resistance to acids, alkalis, solvents, and many other chemicals commonly found in industrial and commercial settings. It can withstand exposure to a wide range of corrosive substances, making it a versatile and durable material for various applications. However, it is worth noting that prolonged exposure to highly concentrated or aggressive chemicals may eventually cause some degradation or deterioration of the fiberglass mat tissue. Therefore, it is essential to consult the manufacturer's specifications and guidelines to ensure proper chemical compatibility and performance in specific environments.

- Q:How does fiberglass mat tissue compare to other types of reinforcement materials?

- Fiberglass mat tissue is a type of reinforcement material that is commonly used in various industries such as construction, automotive, and marine. When comparing fiberglass mat tissue to other types of reinforcement materials, several factors come into play. Firstly, fiberglass mat tissue offers excellent strength and durability. It has high tensile strength, meaning it can withstand considerable pulling or stretching forces without deforming or breaking. This strength is comparable, if not superior, to other reinforcement materials like carbon fiber or aramid fibers. Additionally, fiberglass mat tissue has good resistance to chemical, moisture, and UV degradation, making it suitable for long-term use in various environments. Another advantage of fiberglass mat tissue is its cost-effectiveness. Compared to other reinforcement materials, fiberglass is relatively inexpensive, making it a popular choice for manufacturers and builders who require a cost-efficient solution without compromising on quality. Its affordability makes it accessible to a wider range of applications and industries. Furthermore, fiberglass mat tissue is known for its versatility. It can be molded into various shapes and sizes, allowing for customization and flexibility in design. This adaptability makes fiberglass mat tissue suitable for a wide range of applications, from simple repairs to complex structural reinforcements. However, it is worth noting that fiberglass mat tissue may have some limitations compared to other reinforcement materials. For instance, it may not have the same level of stiffness or strength as carbon fiber, which is often preferred in high-performance applications. Additionally, fiberglass mat tissue may have lower resistance to impact or fatigue compared to materials like aramid fibers. In conclusion, fiberglass mat tissue offers a combination of strength, durability, cost-effectiveness, and versatility that makes it a favorable choice for many applications. While it may have some limitations compared to other reinforcement materials, its overall performance and affordability make it a widely used and reliable option in various industries.

- Q:How does fiberglass mat tissue compare to fiberglass insulation batts?

- Fiberglass mat tissue and fiberglass insulation batts differ in their composition, purpose, and usage. Fiberglass mat tissue, also known as fiberglass veil or fiberglass veil mat, is a thin, non-woven fabric made from fine glass fibers. It is primarily used as a reinforcement material in composites, such as roofing materials, laminates, and automotive parts. The main purpose of fiberglass mat tissue is to add strength, durability, and resistance to cracking or tearing to the final product. It is commonly used in applications where high tensile strength and dimensional stability are required. On the other hand, fiberglass insulation batts are thick, flexible panels made from compressed fiberglass fibers. They are designed specifically for thermal insulation purposes, typically used in residential and commercial buildings. The primary function of fiberglass insulation batts is to create a thermal barrier, reducing heat transfer and improving energy efficiency. They are commonly installed in walls, attics, or crawl spaces to minimize heat loss or gain, providing better temperature control and reducing energy costs. When comparing fiberglass mat tissue to fiberglass insulation batts, it is important to note their distinct purposes and applications. Fiberglass mat tissue is not designed for thermal insulation and should not be used as a substitute for insulation batts. Conversely, fiberglass insulation batts are not suitable as a reinforcement material in composites. In terms of construction and installation, fiberglass mat tissue is typically used in conjunction with other materials, such as resins or adhesives, to form a composite structure. It can be easily cut, shaped, and molded to fit various shapes and sizes. On the other hand, fiberglass insulation batts are available in pre-cut sizes and are relatively easy to install by fitting them between framing studs or joists. Both fiberglass mat tissue and fiberglass insulation batts have their respective advantages and disadvantages, depending on the specific requirements of the project. While fiberglass mat tissue offers superior strength and dimensional stability for composites, fiberglass insulation batts excel in providing thermal insulation for buildings. Ultimately, the choice between the two will depend on the intended application and desired outcome.

- Q:Can fiberglass mat tissue be used for making insulation jackets?

- Yes, fiberglass mat tissue can be used for making insulation jackets. Fiberglass mat tissue is a versatile material that is commonly used in various insulation applications due to its excellent thermal insulation properties. It is lightweight, flexible, and provides effective insulation against heat transfer. When used in insulation jackets, fiberglass mat tissue can help to retain heat and prevent heat loss, making it an ideal choice for applications where thermal insulation is required. Additionally, fiberglass mat tissue is also fire-resistant, which further enhances its suitability for insulation jackets.

- Q:Is fiberglass mat tissue suitable for insulation in laboratories?

- Yes, fiberglass mat tissue is suitable for insulation in laboratories. It offers excellent thermal insulation properties, is resistant to high temperatures, and provides effective sound insulation. Additionally, it is non-combustible and chemically inert, making it ideal for laboratory environments where safety and performance are crucial.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass Unidirectional fabric 227gsm 1000mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords