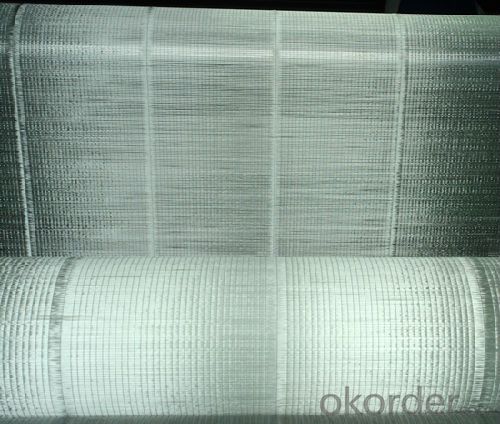

Fiberglass Stitched Mat Triaxial For FRP Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Introductions

E-glass stitched combo mat consists of two or more layers of fiberglass roving which are stitch-bonded.One layer of rovings and different layers of roving can be oriented differently and have different liner density.The roving specification,number of roving layers,mat width and roll diameter can be customized as per requirement.

Multi-axial series: At most 4 layers of roving can be stitched;however a layer of chopped strands(0g/㎡-500g/㎡)or composite materials can be added.The maximal width can be too inched.This product is used in blades of wind power turbines,boat manufacturing and sports devices.

Product Features

Product Specifications

Product no. | Overall Density | 0°Roving Density | .+45°Roving Density | .-45°Roving Density | Chop Density | Polyester Yarn Density |

(g/m2) | (g/m2) | (g/m2) | (g/m2) | (g/m2) | (g/m2) | |

E-TLX600 | 614.9 | 3.6 | 300.65 | 300.65 | - | 10 |

E-TLX750 | 742.67 | 236.22 | 250.55 | 250.55 | - | 5.35 |

E-TLX1180 | 1172.42 | 661.42 | 250.5 | 250.5 | - | 10 |

E-TLX1850 | 1856.86 | 944.88 | 450.99 | 450.99 | - | 10 |

E-TLXM1260/100 | 1367.03 | 59.06 | 601.31 | 601.31 | 100.00 | 5.35 |

E-TXLM1800/225 | 2039.04 | 574.8 | 614.12 | 614.12 | 225 | 11 |

Special specification can be produce according to customer requirements.

FAQ

Packaging:

Each roll is wound onto a paper tube which has an inside diameter of 76mm and the roll has a diameter of 275mm. The roll is wrapped up with plastic film,and then packed in a cardboard box or wrapped up with kraft paper. The rolls can be horizontally placed. For transportation, the rolls can be loaded into a cantainer directly or on pallets.

Storage:

Unless otherwise specified, It should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

- Q:What is the expected lifespan of fiberglass mat tissue in sports facility applications?

- The expected lifespan of fiberglass mat tissue in sports facility applications varies depending on various factors such as maintenance, usage, and environmental conditions. However, with proper care and regular maintenance, fiberglass mat tissue can last for several decades in sports facility applications.

- Q:How is fiberglass mat tissue used in the aerospace industry?

- Fiberglass mat tissue is used in the aerospace industry primarily for its lightweight and high strength properties. It is commonly used as a reinforcement material in the manufacturing of aircraft components such as wings, fuselage, and tail structures. The fiberglass mat tissue provides structural integrity and enhances the overall durability of these components, while also offering excellent resistance to corrosion and high temperatures.

- Q:Is fiberglass mat tissue suitable for agricultural applications?

- Yes, fiberglass mat tissue can be suitable for agricultural applications. It is commonly used in the agricultural industry for various purposes such as reinforcement for greenhouse structures, insulation for livestock housing, and even as a material for composting systems. Its durability, strength, and resistance to weathering make it a viable option for agricultural use.

- Q:How does fiberglass mat tissue perform in high temperatures?

- Due to its inherent heat resistance properties, fiberglass mat tissue is highly effective in high temperatures. The mat is crafted from woven glass fibers, creating a durable and sturdy material. These glass fibers possess a high melting point, enabling the fiberglass mat tissue to endure elevated temperatures without distorting or compromising its structural integrity. Unlike other materials, fiberglass mat tissue does not shrink, warp, or become brittle when exposed to high temperatures. It maintains its dimensional stability and mechanical strength, making it suitable for a wide range of applications in industries such as automotive, aerospace, construction, and insulation. Furthermore, fiberglass mat tissue acts as a thermal insulator, providing protection against heat transfer. It effectively resists heat conduction and radiation, assisting in maintaining the desired temperature in a given environment or preventing heat damage to nearby components. Moreover, fiberglass mat tissue is non-combustible, meaning it does not burn or release toxic gases when subjected to fire. This characteristic makes it a dependable choice for applications that necessitate fire resistance, such as fireproofing insulation or protective barriers. In conclusion, fiberglass mat tissue excels in high temperatures. Its heat resistance, dimensional stability, mechanical strength, thermal insulation properties, and non-combustible nature establish it as an outstanding material for demanding environments where elevated temperatures are present.

- Q:Is fiberglass mat tissue suitable for marine repairs?

- Yes, fiberglass mat tissue is suitable for marine repairs. It is a versatile material that provides excellent strength and durability, making it ideal for fixing and reinforcing various marine structures and components. Fiberglass mat tissue is known for its resistance to water, chemicals, and corrosion, which is essential in a marine environment. It can be used to repair hulls, decks, bulkheads, and other parts of boats and ships, ensuring structural integrity and preventing further damage. Additionally, fiberglass mat tissue is easy to work with and can be applied using various methods, such as wet lay-up or vacuum bagging, making it a popular choice for marine repairs.

- Q:How does fiberglass mat tissue perform in terms of thermal conductivity?

- Fiberglass mat tissue has low thermal conductivity, meaning it is a poor conductor of heat.

- Q:Can fiberglass mat tissue be used in corrosive environments?

- No, fiberglass mat tissue is not suitable for use in corrosive environments as it is not resistant to corrosion.

- Q:Can fiberglass mat tissue be used for architectural facades?

- Yes, fiberglass mat tissue can be used for architectural facades. Fiberglass mat tissue is a lightweight and flexible material that is commonly used in various construction applications, including architectural facades. It offers several advantages such as high strength, durability, weather resistance, and fire resistance. Additionally, fiberglass mat tissue can be easily molded into different shapes and sizes, making it suitable for architectural designs that require unique and intricate facades. Its versatility and aesthetic appeal make it a popular choice among architects and designers for creating visually appealing and functional facades.

- Q:Can fiberglass mat tissue be used for making boat hulls?

- Yes, fiberglass mat tissue can be used for making boat hulls. It is commonly used in boat manufacturing due to its strength, durability, and ability to provide structural reinforcement.

- Q:What are the different finishing options available for fiberglass mat tissue?

- Fiberglass mat tissue offers a variety of finishing options to meet specific needs. One popular choice is applying a resin coating, which protects and strengthens the fibers while giving the material a smooth and glossy look. Another option is a fire-retardant treatment, which involves applying a special chemical to reduce flammability. This is crucial for industries where fire safety is a concern, like construction. Color customization is also possible by adding dye or pigment during manufacturing. This allows for a wide range of visually appealing options. For a more tactile and aesthetically pleasing product, a textured finish can be applied to the surface. This is useful in applications requiring grip or slip resistance. Lastly, a laminated backing can be used to bond the fiberglass mat tissue to materials like foam or fabric, adding strength and flexibility. In summary, fiberglass mat tissue offers various finishing options to enhance its performance and appearance in different industries. The ability to customize strength, fire resistance, color, texture, and backing makes it a versatile choice.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass Stitched Mat Triaxial For FRP Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords