Fiberglass Stitched Combo Mat

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 12000 kg

- Supply Capability:

- 200000Kg Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

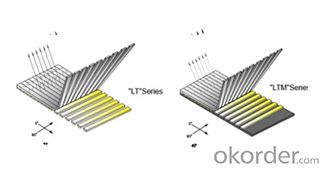

(0°/90°) series mat:

Two layers of roving(550g/㎡-1250g/㎡) are aligned at 0°/90° with or without a layer of chopped strands(0g/㎡-500g/㎡)。The product has a maximum width of 100 inches.This product can be used for manufacturing boats,cases and shell of car.

2.Product Structure

3.Product Specifications

Product No. | Overall Density | .0° Roving Density | .90° Roving Density | Chop Density | Polyester Yarn Density |

(g/m2) | (g/m2) | (g/m2) | (g/m2) | (g/m2) | |

E-LTMC1603 | 671.74 | 303.8 | 247.96 | 101.62 | 18.36 |

E-LTMC1608 | 844.76 | 303.8 | 247.96 | 274.64 | 18.36 |

E-LTMC1808 | 903.8 | 303.8 | 307 | 274.64 | 18.36 |

E-LTMC1810 | 934.31 | 303.8 | 307 | 305.15 | 18.36 |

E-LTMC1815 | 1086.89 | 303.8 | 307 | 457.73 | 18.36 |

E-LTMC2408 | 1101.04 | 405.66 | 401.46 | 274.64 | 19.28 |

E-LTMC2415 | 1284.13 | 405.66 | 401.46 | 457.73 | 19.28 |

E-LTMC3205 | 1272.69 | 607.6 | 491.86 | 152.58 | 20.65 |

E-LTMC3205-HS | 1388.43 | 607.6 | 607.6 | 152.58 | 20.65 |

E-LTMC3208 | 1394.75 | 607.6 | 491.86 | 274.64 | 20.65 |

E-LTMC3610 | 1541 | 607.6 | 607.6 | 305.15 | 20.65 |

E-LTMC3615 | 1693.58 | 607.6 | 607.6 | 457.73 | 20.65 |

E-LTC1800 | 629.16 | 303.8 | 307 | - | 18.36 |

E-LTC2400 | 826.4 | 405.66 | 401.46 | - | 19.28 |

E-LTC3600 | 1235.85 | 607.6 | 607.6 | - | 20.65 |

E-UDL450 | 479.14 | 405.66 | 55.12 | - | 18.36 |

E-UDL500 | 490.85 | 405.66 | 66.83 | - | 18.36 |

E-UDL600 | 608.9 | 566.92 | 23.62 | - | 18.36 |

E-UDL1200 | 1207.34 | 1133.86 | 55.12 | - | 18.36 |

E-UDLM1250 | 1258.98 | 1133.86 | 55.12 | 50.00 | 20 |

E-UDLM1300 | 1338.68 | 1215.2 | 55.12 | 50.00 | 18.36 |

Special specification can be produce according to customer requirements.

4.FAQ

Packaging:

Each roll is wound onto a paper tube which has an inside diameter of 76mm and the roll has a diameter of 275mm. The roll is wrapped up with plastic film,and then packed in a cardboard box or wrapped up with kraft paper. The rolls can be horizontally placed. For transportation, the rolls can be loaded into a cantainer directly or on pallets.

Storage:

Unless otherwise specified, It should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

- Q:What is the average thickness of fiberglass fabric?

- The average thickness of fiberglass fabric typically ranges between 0.2 to 0.5 millimeters.

- Q:How does fiberglass fabric handle abrasion in mining operations?

- Due to its outstanding durability and resistance to wear and tear, fiberglass fabric is a superior option for managing abrasion in mining operations. In the harsh conditions commonly found in mining, where abrasive materials like rocks, stones, and minerals are frequently encountered, fiberglass fabric withstands the test. The high tensile strength of fiberglass fabric is one of its key properties, allowing it to endure constant rubbing and scraping against abrasive surfaces. The tightly woven structure of the fabric acts as a protective shield, preventing abrasive particles from penetrating and causing damage. Furthermore, fiberglass fabric exhibits remarkable resistance to chemical corrosion, a common occurrence in mining environments. It can endure exposure to acids, alkalis, and other corrosive substances commonly found in mining operations. This resistance guarantees that the fabric remains intact and functional even in the presence of harsh chemicals, thus enhancing its durability against abrasion. Moreover, fiberglass fabric possesses excellent heat resistance, making it suitable for mining operations involving high temperatures. It can withstand extreme heat conditions without compromising its structural integrity or performance. This characteristic is particularly essential in operations such as smelting, which involve intense heat. Additionally, fiberglass fabric is lightweight and flexible, making it easy to handle and install in mining equipment. Its flexibility allows it to conform to irregular shapes and surfaces, ensuring a secure fit and maximum protection against abrasion. To summarize, fiberglass fabric is an ideal choice for handling abrasion in mining operations due to its exceptional durability, resistance to wear and tear, chemical corrosion resistance, and heat resistance. Its high tensile strength, flexibility, and lightweight nature make it a reliable and practical solution for safeguarding mining equipment and machinery from the abrasive forces encountered in these operations.

- Q:Is fiberglass fabric resistant to chemicals used in oil and gas industry?

- Yes, fiberglass fabric is generally resistant to the chemicals used in the oil and gas industry. Fiberglass is known for its excellent chemical resistance, making it suitable for various industrial applications, including oil and gas. It can withstand exposure to a wide range of chemicals, including acids, alkalis, solvents, and hydrocarbons commonly found in the oil and gas industry. This resistance is due to the inert nature of the fiberglass material, which does not react or degrade when exposed to these chemicals. Additionally, the fabric's non-porous structure prevents the absorption of chemicals, further enhancing its resistance. Overall, fiberglass fabric is an ideal choice for applications requiring chemical resistance in the oil and gas industry. However, it is always recommended to consult with manufacturers or suppliers to ensure the specific type of fiberglass fabric being used is suitable for the intended chemical environment.

- Q:Are there any specific certifications or standards for fiberglass fabrics?

- Yes, there are specific certifications and standards for fiberglass fabrics. One of the most widely recognized certifications for fiberglass fabrics is the ISO 9001:2015 certification, which signifies that the manufacturer has implemented a quality management system and meets the international standards for product quality. In addition, there are specific standards developed by organizations like ASTM International (formerly known as the American Society for Testing and Materials) that outline the testing methods and performance requirements for fiberglass fabrics. For example, ASTM D579-67(2013) provides standard specifications for glass fiber fabrics, while ASTM D3774-16a covers the testing of woven fabrics. Furthermore, there are industry-specific certifications that fiberglass fabric manufacturers may seek, such as the NORSOK M-710 certification for offshore applications or the MIL-STD-810 certification for military-grade fabrics. These certifications and standards help ensure that fiberglass fabrics meet certain quality, safety, and performance criteria. They provide customers with confidence in the product's reliability and help manufacturers demonstrate their commitment to producing high-quality fiberglass fabrics.

- Q:How to distinguish the good and bad of aluminum foil glass fiber cloth? What is the plain glass fiber cloth, glass fiber cloth and twill satin glass cloth?

- Satin glass cloth. Is referred to as a variety of satin glass fiber cloth organization. Including all kinds of glass fiber cloth satin and sateen change organization, different specifications of different styles of fabric.

- Q:How strong is fiberglass fabric?

- Fiberglass fabric is known for its exceptional strength and durability. It is composed of glass fibers that are woven together to form a strong and flexible material. The strength of fiberglass fabric can vary depending on factors such as the density of the weave and the specific type of glass used. In general, fiberglass fabric is considered to be stronger than many other traditional fabrics, such as cotton or polyester. It has high tensile strength, meaning it can withstand significant pulling or stretching forces without breaking or tearing. Fiberglass fabric is also highly resistant to heat, chemicals, and UV radiation, making it suitable for a wide range of applications. Overall, fiberglass fabric is renowned for its strength, making it a preferred choice in industries such as construction, automotive, aerospace, and marine.

- Q:What are the different weight options for fiberglass fabric?

- Fiberglass fabric comes in various weight options, which determine its thickness and density. Manufacturers and intended applications can influence the weight options available. Fiberglass fabric weight is typically measured in ounces per square yard (oz/yd²) or grams per square meter (g/m²). Different weight options for fiberglass fabric exist, depending on the manufacturer and intended use. Common weight options include 1.5 oz/yd², 3 oz/yd², 6 oz/yd², 9 oz/yd², and 18 oz/yd². These weights indicate the number of fiberglass strands per unit area, with higher weights indicating a denser fabric. Lighter weight fiberglass fabrics, like 1.5 oz/yd², find application in projects requiring flexibility and a smooth finish, such as surfboards, model airplanes, and lightweight structures. The automotive industry also commonly utilizes them for interior parts or as reinforcement in composite materials. Medium weight fiberglass fabrics, ranging from 3 oz/yd² to 9 oz/yd², serve general-purpose applications, including boat building, mold making, and repairing or reinforcing structures. These weight options strike a balance between flexibility and strength, making them suitable for a wide range of projects. Heavier weight fiberglass fabrics, such as 18 oz/yd², come into play when maximum strength and durability are necessary. They find common use in industrial applications like tank and pipe wrapping, as well as in the construction industry for reinforcing concrete or other structural elements. It is important to consider that the weight of fiberglass fabric is just one factor to contemplate when choosing the appropriate fabric for a specific application. Other factors, like weave pattern, resin compatibility, and intended use, should also be taken into account to ensure the desired performance and outcome.

- Q:Can fiberglass fabric be used for reinforcement in marine applications?

- Yes, fiberglass fabric can be used for reinforcement in marine applications. It is commonly used in boat manufacturing and repairs due to its high strength, durability, and resistance to water and corrosion.

- Q:What are the different weights available in fiberglass fabric rolls?

- Fiberglass fabric rolls are available in a variety of weights to suit different applications and requirements. The weights of fiberglass fabric rolls typically range from 3 ounces per square yard (oz/yd²) to 50 oz/yd² or even higher. The weight of a fiberglass fabric roll refers to the amount of glass fibers contained in a square yard of the fabric. Generally, the higher the weight, the thicker and stronger the fabric will be. Lightweight fiberglass fabric rolls, such as those weighing 3-8 oz/yd², are often used for applications that require flexibility, such as boat building, surfboard laminations, or repairs on small objects. These lightweight fabrics are easy to handle and conform well to curved surfaces. Medium weight fiberglass fabric rolls, ranging from 10-20 oz/yd², are commonly used for general-purpose applications, such as reinforcing or repairing fiberglass structures, making molds, or creating composite parts. These fabrics provide a good balance between strength and flexibility. Heavyweight fiberglass fabric rolls, with weights ranging from 20-50 oz/yd² or more, offer exceptional strength and are often used for demanding applications that require high structural integrity, such as aerospace, automotive, or marine industries. These fabrics are suitable for building strong, rigid structures or providing reinforcement in high-stress areas. It is important to select the appropriate weight of fiberglass fabric roll based on the specific needs of your project. Factors to consider include the desired strength, flexibility, and durability required, as well as the complexity of the shape or structure being reinforced. Consulting with a fiberglass fabric expert or supplier can help ensure that you choose the right weight for your specific application.

- Q:Can fiberglass fabric be used in low-temperature applications?

- Yes, fiberglass fabric can be used in low-temperature applications. It is known for its excellent thermal insulation properties, making it suitable for use in environments with low temperatures. Additionally, fiberglass fabric retains its strength and flexibility even in extreme cold, making it a reliable choice for various low-temperature applications such as insulation, cryogenic storage, and cold weather clothing.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass Stitched Combo Mat

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 12000 kg

- Supply Capability:

- 200000Kg Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords