Fiberglass Roofing Panels(Sheets) for Constructin Using

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Roofing Panels(Sheets) for Constructin Using

Description

In general, our company specializes in FRP grating, FRP decking, FRP platform and other products of FRP. We have a varity of FRP products sold over the country because we have our own teams of design, manufacturing and sales with hundreds of staffs.

At the same time, we are devoted to creating a production and marketing for FRP products, which has certain influence in China by proceeding with professional teams, rigorous quality management system and advanced production facility.

Today, we’re planning to win more market shares in the world and let more customers know us.

Photos

Product Traits

1. The intensity and stiffness is quite prominent,.

2. Lightweight, high strength pultrusion process molding FRP profiles have high glass fiber content (60%). In this situation, the density of glass fiber reinforced plastic is only about a quarter of the steel.

3. Corrosion resistance no rust, no maintenance, long service life.

4. Anti-fatigue high anti- fatigue strength, allowing repeated bending without permanent deformation.

5. Anti-aging select highquality FRP pultrusion profiles, the service life of the product can be more than 20 years.

6. Anti-UV agent are added into all pultrusion FRP profiles get the best anti-uv effect.

Product Advantage

Coated with prevent aging layer

Excellent insulating performance

- High strength.

Easy to maintain.

Long service life.

Easy to install.

Good light transmittance.

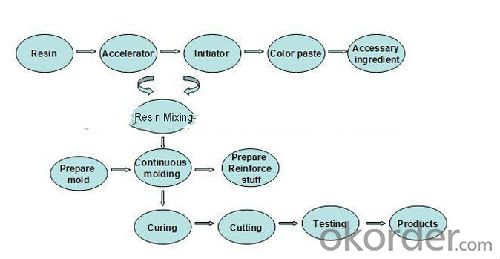

Production Process

Specification&Technical Parameters

Mechanical properties: high rigidity lighting panels

Plate matches: match with general prepainted galvanized sheet, galvanized steel

Resin composites: Improved anti-aging SMR198 resin

Fiber reinforcement: E-glass fiber untwisted without glue

Surface treatment: affixing MELINEX301 film

Stiffener line: surface with longitudinal uniform distribution of anti-LAC gluten

Glass fiber: not less than 28%

Unit Weight: 1800g / ㎡, 2400g / ㎡, 3050g / ㎡

Nominal thickness: 1.2 mm, 1.5mm, 2.0mm (tolerance ≤ 10%)

Temperature limits: -60 ℃ ~ +130 ℃

Transmittance (1.5mm): 72% ± 2% (fog white, sky blue, water green), 52% ± 2% (white porcelain)

UV-rate: 99%

Tensile strength: 90Mpa

Flexural strength: 160 Mpa

Elongation: 1.9%

Pap hardness: ≥ 50

Thermal expansion coefficient: 1.5 ~ 3.2 * 10-5 / K

Thermal conductivity: K = 0.23W / m * K

Guarantee: 15 years

NOTE: In special cases, the surface film varieties vary according to needs, such as Melinex389, PT055 and so on.

FAQ

1.Which country do you mainly export to?

A: Our products are very popular in Mid East, India, South East Asia, Latin America, Africa.

2.Q: Would you like to let us get your sampels?

A: Yes, of course. We will send you samples for your confirmation before you place firm orders.

- Q:Can fiberglass fabrics be used for protection against electromagnetic interference?

- Yes, fiberglass fabrics can be used for protection against electromagnetic interference. Their low electrical conductivity and excellent dielectric properties make them effective as shielding materials, blocking or reducing the penetration of electromagnetic waves.

- Q:What is the typical tensile strength of fiberglass fabrics?

- The typical tensile strength of fiberglass fabrics can vary, but it is generally around 300-600 MPa (megapascals).

- Q:Can fiberglass fabric be used for reinforcement in plastic parts?

- Indeed, reinforcement of plastic parts can be achieved through the utilization of fiberglass fabric. Renowned for its exceptional strength and durability, fiberglass fabric serves as an optimal selection for bolstering plastic components. By incorporating the fabric within the plastic material, it imparts enhanced resilience, rigidity, and resistance against deformation. This reinforcement proves particularly advantageous in situations requiring plastic parts to endure substantial loads, impacts, or extreme temperatures. Moreover, fiberglass fabric aids in improving the dimensional stability of plastic parts, consequently mitigating the likelihood of warping or distortion. Consequently, fiberglass fabric finds extensive application across various industries, effectively augmenting the mechanical properties and overall performance of plastic parts.

- Q:What is the advantage of coating waterproof layer with matrix reinforcing material?

- Waterproof layer construction, often in a waterproof coating is added in the glass fiber cloth or polyester fiber cloth as matrix reinforced material, its main purpose is: with the carcass reinforcing material deformability of gutter, eaves gutter, eaves, the water node location details, because the temperature deformation of roof structure is not synchronized, easy to deform and crack therefore, caused by leakage, in roof waterproof weak parts must be in the construction of large area coating waterproof layer, easy to leak in these lines or at least additional outward widening 200mm layer is coated with a cloth, enhance the anti deformation ability of waterproof film.

- Q:Are there any specific installation instructions for fiberglass fabrics?

- Yes, there are specific installation instructions for fiberglass fabrics. When installing fiberglass fabrics, it is important to follow certain steps to ensure proper installation and maximize their effectiveness. Here are some general guidelines to consider: 1. Surface Preparation: Before installing fiberglass fabrics, it is crucial to prepare the surface properly. Ensure that the surface is clean, dry, and free from any debris, dust, or contaminants that might hinder the adhesion of the fabric. 2. Adhesive Selection: Choose an appropriate adhesive that is compatible with fiberglass fabrics and the surface you are working on. Consult the manufacturer's guidelines to select the most suitable adhesive for the specific application. 3. Cutting and Sizing: Measure and cut the fiberglass fabric according to the desired dimensions, ensuring that it provides ample coverage for the intended area. Use sharp scissors or a utility knife to achieve clean and precise cuts. 4. Application of Adhesive: Apply a thin and even layer of the chosen adhesive onto the prepared surface using a brush, roller, or a trowel. Make sure to follow the manufacturer's instructions regarding the adhesive application and drying times. 5. Placement of Fiberglass Fabric: Carefully place the cut fiberglass fabric onto the adhesive-coated surface. Avoid stretching or wrinkling the fabric during installation. Gently smooth out any air bubbles or creases using a roller or a squeegee, ensuring proper adhesion. 6. Additional Layers: If necessary, apply additional layers of fiberglass fabric, overlapping the edges by a few inches to ensure a seamless and durable installation. Follow the same procedure for each layer, applying adhesive and smoothing out any imperfections. 7. Curing Time: Allow sufficient time for the adhesive to cure and the fiberglass fabric to bond securely to the surface. The curing time may vary depending on the type of adhesive used and environmental conditions. Refer to the manufacturer's instructions for the recommended curing time. 8. Finishing Touches: Once the adhesive has fully cured, trim any excess fiberglass fabric using a sharp utility knife. Sand down any rough edges or uneven surfaces for a smooth finish. Remember to always consult the manufacturer's instructions specific to the fiberglass fabric and adhesive you are using, as different products may have unique installation requirements. Additionally, if you are unsure or uncomfortable with the installation process, it is recommended to seek professional assistance to ensure a successful and safe installation.

- Q:Are there any health risks associated with exposure to fiberglass fabrics?

- Yes, there can be health risks associated with exposure to fiberglass fabrics. Fiberglass is made of tiny fibers that are sharp and can easily become airborne when the fabric is disturbed or damaged. When these fibers are inhaled or come into contact with the skin, they can cause irritation, itching, and redness. Prolonged exposure to fiberglass fibers can also lead to more serious health issues such as respiratory problems, lung damage, and even cancer. In addition to direct contact, fiberglass fabrics can also release small particles into the air, making them a potential respiratory hazard. Breathing in these particles can cause coughing, wheezing, and shortness of breath. People with pre-existing respiratory conditions such as asthma or chronic obstructive pulmonary disease (COPD) may be particularly susceptible to these effects. To minimize the health risks associated with fiberglass fabrics, it is important to take precautions when working with or around them. This includes wearing appropriate personal protective equipment such as gloves, goggles, and a respiratory mask to prevent direct contact and inhalation of the fibers. It is also important to handle fiberglass fabrics carefully to avoid damaging them and releasing fibers into the air. If you suspect that you have been exposed to fiberglass fibers and are experiencing any symptoms such as skin irritation or respiratory issues, it is advisable to seek medical attention. A healthcare professional can assess your condition and provide appropriate treatment if necessary.

- Q:Are fiberglass fabrics resistant to rot or decay?

- Yes, fiberglass fabrics are inherently resistant to rot or decay due to their non-organic composition and durable properties.

- Q:How is fiberglass fabric used in the production of automotive body parts?

- Fiberglass fabric is commonly used in the production of automotive body parts due to its numerous advantageous properties. It is a lightweight and strong material, making it ideal for creating durable and efficient automotive components. One of the primary uses of fiberglass fabric in the production of automotive body parts is in the manufacturing of car hoods. Fiberglass hoods are popular among car enthusiasts because they are significantly lighter than traditional metal hoods, thereby reducing the overall weight of the vehicle. This decrease in weight can result in improved fuel efficiency and enhanced performance. Additionally, fiberglass fabric is used in the production of fenders, spoilers, and other exterior body panels. These components need to be lightweight, yet robust enough to withstand road debris, impacts, and weather conditions. Fiberglass fabric provides the necessary strength and durability while also allowing for intricate design shapes and contours. Moreover, fiberglass fabric is used in the fabrication of interior automotive parts. It is commonly employed in the production of door panels, dashboard covers, and trim pieces. These components require a material that is both flexible and durable, and fiberglass fabric fits this criterion perfectly. It can be easily molded into various shapes and sizes, allowing for customization and achieving a sleek, modern aesthetic. In the manufacturing process, fiberglass fabric is typically combined with a resin matrix, such as polyester or epoxy, to create a composite material. The fabric is first impregnated with the resin, and then it is molded or pressed into the desired shape using heat and pressure. This process ensures that the fiberglass fabric adheres well to the resin, resulting in a strong and rigid final product. In conclusion, fiberglass fabric plays a vital role in the production of automotive body parts. Its lightweight nature, strength, durability, and versatility make it an excellent choice for creating various exterior and interior components. By utilizing fiberglass fabric, automakers can achieve both performance enhancements and aesthetic appeal in their vehicles.

- Q:Can fiberglass fabric be used for making speaker cones?

- Speaker cones can indeed be made using fiberglass fabric. This material is known for being lightweight, rigid, and long-lasting, making it a popular choice in constructing speaker cones. Its high strength-to-weight ratio is essential for preserving the cone's structure and responsiveness. Moreover, fiberglass fabric can be shaped into different sizes and forms, enabling manufacturers to create speaker cones with diverse designs and performance features. The material also possesses favorable acoustic properties, contributing to the overall sound quality produced by the speaker. Nevertheless, it is important to note that the specific characteristics and performance of a speaker cone depend on multiple factors, such as design, materials, and manufacturing processes. Consequently, while fiberglass fabric is a viable option for making speaker cones, it is just one of several alternatives accessible to manufacturers.

- Q:Is fiberglass fabric resistant to fire in public buildings?

- Yes, fiberglass fabric is indeed resistant to fire and is commonly used in public buildings for its fire-retardant properties. Fiberglass fabric is made from woven glass fibers that are highly heat resistant and do not easily catch fire. It has a high melting point, which means it will not ignite or support combustion easily. Moreover, fiberglass fabric is often treated with fire-resistant coatings or chemicals to further enhance its fire resistance. These properties make it an ideal material for use in public buildings, where safety and fire protection are of utmost importance.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass Roofing Panels(Sheets) for Constructin Using

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords