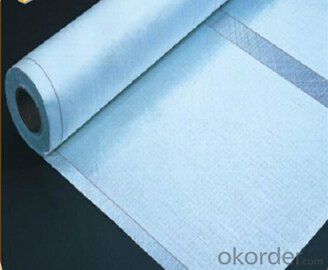

Fiberglass Multiaxial Fabric-UD,950gsm, 0°:750g chopping:200g

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

◎ This fabric is made of fiberglass roving which are aligned at 0° or 90° into one layer of roving by stitching together with or without one layer of chopped strand. It is mainly applied in the hand lay up, RTM and other close molding processes.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Application | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Mainly be used as reinforced materials in the composite material industry: engine room casing, wind deflector, boat, auto frame and pultrusion profiles,etc.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

◎ Small gap between fibers, Increased strength, reduced product weight and better surface finish. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Each roll is wrapped by PE film and then packed into carton. Stacking in bulk or palletized is available; the pallet shall be no higher than 2 layers.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

FAQ

A:Are you a manufacturer or trading company?

Q:Low price can be offered to you because we are not only a trade company but a manufacturer.We have our factory.

A: How Long have you been in this line for fiberglass?

Q: 10 years working experiences specializing in the production and sale of Fiberglass and other related products.

- Q:Can fiberglass mat tissue be used for flooring applications?

- No, fiberglass mat tissue is not typically used for flooring applications. It is commonly used in industries such as automotive, construction, and marine for insulation, reinforcement, and insulation purposes. Flooring applications usually require different materials such as tiles, hardwood, laminate, or vinyl.

- Q:Is fiberglass mat tissue suitable for outdoor applications?

- Yes, fiberglass mat tissue is suitable for outdoor applications. It is highly durable, weather-resistant, and can withstand exposure to harsh environmental conditions such as sunlight, rain, and extreme temperatures. Additionally, it provides excellent strength and insulation properties, making it a reliable choice for various outdoor applications, including construction, roofing, and insulation.

- Q:How is fiberglass mat tissue used in the production of water tanks?

- Fiberglass mat tissue, which is made from glass fibers and falls under the category of non-woven fabric, is widely utilized in the manufacturing of water tanks due to its exceptional strength, durability, and resistance to corrosion. Typically, water tanks are constructed using fiberglass reinforced plastic (FRP), a composite material comprising a polymer matrix with fiberglass reinforcement. In this process, the fiberglass mat tissue plays a vital role as the material for reinforcement. To begin, the fiberglass mat tissue is cut into the desired shape and size to fit the mold of the water tank. It is then applied in layers onto the mold, with the number of layers determined by the required strength and thickness of the tank. Once in place, a resin matrix is used to impregnate and bind the fibers of the fiberglass mat tissue together. The specific resin employed, whether polyester, vinyl ester, or epoxy, depends on the particular requirements of the water tank. Typically, the resin is applied by either spraying or using a roller, ensuring complete saturation of the fiberglass mat tissue. This process is often repeated multiple times to achieve the desired thickness and strength of the tank. After the resin has cured, the fiberglass mat tissue and resin composite become rigid, forming the structure of the water tank. The resulting FRP tank is lightweight yet remarkably strong and durable, making it an excellent choice for water storage and transportation. The use of fiberglass mat tissue in water tank production offers several advantages. Firstly, it enhances the structural integrity of the tank, enabling it to withstand external forces such as pressure and impact. Secondly, fiberglass exhibits a high resistance to corrosion, ensuring that the tank remains in optimal condition even when exposed to harsh environmental conditions or corrosive substances present in the water. In conclusion, fiberglass mat tissue is an essential element in the production of water tanks, providing strength, durability, and corrosion resistance. This makes it a reliable option for various industrial, commercial, and residential applications.

- Q:Can fiberglass mat tissue be used for repairing damaged fiberglass structures?

- Yes, fiberglass mat tissue can be used for repairing damaged fiberglass structures. The mat tissue is designed to provide strength and reinforcement to the damaged area, making it an effective solution for repairing fiberglass structures.

- Q:Can fiberglass mat tissue be used for repairing fiberglass canoes?

- Yes, fiberglass mat tissue can be used for repairing fiberglass canoes. It is commonly used to reinforce and strengthen the damaged areas of the canoe by providing additional structural support.

- Q:Is fiberglass mat tissue resistant to fading?

- Yes, fiberglass mat tissue is resistant to fading.

- Q:Can fiberglass mat tissue be used for reinforcing concrete?

- Yes, fiberglass mat tissue can be used for reinforcing concrete. It is often used as a reinforcement material in construction for its high tensile strength and durability. The fiberglass mat tissue helps to increase the overall strength and structural integrity of the concrete, making it suitable for various applications such as building foundations, road pavements, and precast concrete products.

- Q:Is fiberglass mat tissue biodegradable?

- No, fiberglass mat tissue is not biodegradable. Fiberglass is a synthetic material made from fine fibers of glass, which are woven together to create a strong and durable material. These fibers do not break down naturally over time, making fiberglass mat tissue non-biodegradable.

- Q:Can fiberglass mat tissue be used for waterproofing?

- Yes, fiberglass mat tissue can be used for waterproofing. Fiberglass mat tissue is a thin, non-woven material that is made from fiberglass fibers. It is commonly used in construction and building applications to provide reinforcement and waterproofing properties. When applied with a waterproofing agent or resin, the fiberglass mat tissue can create a waterproof barrier that helps to prevent the passage of water or moisture. This makes it an effective choice for applications such as roofing, basement waterproofing, and bathroom or shower installations. The strength and durability of fiberglass mat tissue also make it resistant to cracking or tearing, ensuring long-lasting waterproofing protection.

- Q:What are the common sizes available for fiberglass mat tissue?

- The common sizes available for fiberglass mat tissue vary, but typically range from 1.27 meters (50 inches) to 2.54 meters (100 inches) in width, and can be customized to desired lengths by manufacturers.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass Multiaxial Fabric-UD,950gsm, 0°:750g chopping:200g

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords