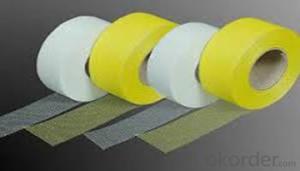

Fiberglass Mesh Gummed Adhesive Tape Double Side Waterproof

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 roll

- Supply Capability:

- 500000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. product show

2.Product specification

| 1.Base Material: | BOPP Film(Biaxillary Oriented Poly Propylene Film) |

| 2.Adhesive Coating: | Emulsion Pressure Sensitive Water Base Butyl Acrylic |

| 3.Printability: | Up to 3 colors as per specifications by Rotogravure Printing. |

| 4.Peeling Strength With 180#730: | 4.5~7N/2.5CM |

| 5.180 Peel Adhesion: | 2N/CM |

3.Our advangtages

1.BOPP tape, superb tack and adhesion to surface. Strong grip that is ensured because of an excellent adhesive backing.

Quality processing equipment that guarantees consistent quality.

2.Peak performance even under extereme conditions of pressure and temperature. Sticks on all types of surfaces.(paper, plastic, wood,glass,fiber,metal,etc)

3.Consistent quality; 4.On time delivery; 5.Effective and timely communication; 6.Competitive price.

4.Company information

CNBM International Cooperation is a subsidiary company of CNBM Group, which is one of the biggest state-owned company and Fortune 500 companies in the world.

All of our products are very affordable as a result of being produced in special economic development regions of China and we are more than happy to help you with the import/exportprocess too!

5.Our service

(1)24 hours prompt reply by email or telephone or messenger.

(2)Standard size have stock, immediately delivery once your purchase

(3)10 days delivery containers for out of stock

(4)Can combine containers with multiple insulation products for your different demand

(5)No quantity limit, from 1 rolls to full container, at your choose and demand!

6.FAQ

(1) Payment: 50% T/T DEPOSIT PAYMENT IN ADVANCE, BALANCE AGAINST COPY OF B/L, WESTERN UNION, L/C.

(2) Production Lead Time: 10 - 20 DAYS AFTER DEPOSIT PAYMENT.

(3) Shipping Methods: OCEAN FREIGHT.

(4) FOB Shipping port: Tianjin, MAINLAND CHINA.

(5) If you want to deal with EXW/CIF/CNF term instead of FOB, please specify. Otherwise, FOB price will be quoted under inquiry.

- Q:For the moment the yellow rubber stamp [] how to use paper and pen, pen parts packaging tape?

- Circle, circle, lap, wrap the tail and cut off the excess!

- Q:Can packaging tape be used for sealing packages with electronic components?

- Yes, packaging tape can be used for sealing packages with electronic components. Packaging tape is designed to provide a secure and durable seal for packages, protecting the contents from external elements such as moisture, dust, and physical damage. When sealing packages with electronic components, it is important to ensure that the tape is strong enough to hold the package together and provide adequate protection. It is also recommended to use anti-static packaging tape specifically designed for electronic components, as it helps dissipate static electricity and prevent any potential damage to sensitive electronics.

- Q:How do I cut packaging tape without scissors?

- If you don't have scissors, there are several alternative methods you can use to cut packaging tape. One option is to use a sharp knife or a utility knife, making sure to exercise caution and keep your fingers away from the blade. Another method is to use a box cutter or a pocket knife, again being careful to handle it safely. If you don't have any cutting tools available, you can try tearing the tape by firmly gripping it with both hands and pulling it apart swiftly. However, this method may not always result in a clean cut. Additionally, you can try using your teeth to tear the tape, but this is not recommended as it could potentially damage your teeth or cause injury. Remember to always prioritize safety and exercise caution when using any sharp objects to cut packaging tape.

- Q:What are the considerations for using packaging tape on wooden surfaces?

- There are several factors to consider when using packaging tape on wooden surfaces. Firstly, it is crucial to select the appropriate type of tape for the wood. Choose a tape specifically designed for wood or one with a gentle adhesive to prevent damage or residue. Avoid strong adhesive or duct tapes that may leave sticky residue or peel off the wood's finish. Secondly, take into account the condition of the wood. If it is old, fragile, or has cracks, extra precautions are necessary. Applying tape directly to damaged or delicate wood can cause further harm, such as stripping the varnish or causing splintering. In such cases, alternative methods should be used to secure or protect the wood. Consider the duration for which the tape will be applied. If it is temporary, most types of packaging tape are generally safe to use. However, if the tape will be left on the wood for an extended period, choose a tape that is less likely to damage or leave residue when removed. Additionally, be mindful of the climate or environment in which the wood will be situated. Extreme temperatures or humidity can affect the adhesive properties of the tape, potentially causing it to lose stickiness or damage the wood. In such cases, alternative methods may be required to secure or protect the wood. Lastly, always test a small, inconspicuous area of the wood with the tape before applying it extensively. This allows for assessment of any potential damage or residue and helps make an informed decision about using the tape on the entire wood surface. By considering these factors, one can ensure the safe use of packaging tape on wooden surfaces without causing unnecessary damage or issues.

- Q:Does packaging tape come in different colors?

- Yes, packaging tape does come in different colors. While the most common color for packaging tape is clear, there are also a variety of colors available to meet different needs and preferences. Some examples of colored packaging tape include red, blue, green, yellow, and black. These colored tapes can be used for various purposes such as color-coding different packages, indicating priority shipments, or simply adding a pop of color to your packaging. Additionally, colored packaging tape can also be used for decorative or artistic purposes, making it a versatile option for both practical and creative applications.

- Q:Can packaging tape be used for sealing plastic wrap?

- Yes, packaging tape can be used for sealing plastic wrap. It provides a strong adhesive bond that helps secure the plastic wrap in place, keeping the contents protected and sealed.

- Q:Can packaging tape be used for sealing foam?

- Yes, packaging tape can be used for sealing foam. It provides a secure and reliable way to hold foam pieces together or close gaps in foam packaging. However, it's important to note that there are specific types of tape designed for foam sealing, such as foam tape or adhesive-backed foam strips, which may offer better results and durability.

- Q:Does packaging tape come in different dispenser options for ease of use?

- Yes, packaging tape does come in different dispenser options for ease of use. There are various types of dispensers available, including handheld tape guns, tabletop dispensers, and automatic tape dispensers, each designed to provide convenience and efficiency while using packaging tape.

- Q:What are the benefits of using UV-resistant packaging tape?

- There are several benefits of using UV-resistant packaging tape. First and foremost, UV-resistant packaging tape is designed to withstand prolonged exposure to sunlight and prevents the tape from deteriorating or degrading over time. This is especially important when shipping or storing items outdoors or in areas with direct sunlight. UV-resistant tape can maintain its adhesive properties and structural integrity for longer periods, ensuring that packages remain securely sealed. Additionally, UV-resistant packaging tape helps protect the contents of packages from damage caused by UV rays. Sunlight can cause fading, discoloration, or degradation of certain materials, such as paper, fabrics, or plastics. By using UV-resistant tape, these items are shielded from the harmful effects of UV rays, preserving their quality and appearance. Another advantage of UV-resistant packaging tape is its long-lasting adhesion. Unlike regular packaging tape, which may lose its stickiness over time when exposed to sunlight, UV-resistant tape is specifically formulated to bond tightly and securely to various surfaces. This reliable adhesion minimizes the risk of packages coming open or items getting damaged during transit. Moreover, UV-resistant packaging tape provides added peace of mind for both the sender and the recipient. By using tape that is resistant to UV rays, businesses and individuals can ensure that their packages arrive in the same condition they were sent, maintaining the professional image and customer satisfaction. This is particularly crucial when shipping valuable or delicate items that require extra protection. In conclusion, the benefits of using UV-resistant packaging tape include enhanced durability, protection against UV damage, long-lasting adhesion, and increased confidence in package integrity. By choosing UV-resistant tape, individuals and businesses can safeguard their packages and the contents within, even when exposed to prolonged sunlight.

- Q:Can packaging tape be used for sealing electronics or appliances?

- Packaging tape is not recommended for sealing electronics or appliances. While packaging tape is designed to securely seal cardboard boxes and packages, it is not suitable for sealing electronics or appliances due to various reasons. Firstly, packaging tape does not provide adequate protection against moisture or dust, which can be harmful to electronic components. Electronics and appliances require airtight sealing to prevent any damage or corrosion caused by moisture or dust particles. Secondly, packaging tape is not designed to withstand high temperatures or extreme conditions that electronics or appliances may be subject to during storage or transportation. The adhesive used in packaging tape may not be able to withstand heat or cold, which could lead to the tape peeling off and leaving the item unprotected. Thirdly, electronics and appliances often have delicate surfaces that can be easily scratched or damaged by the adhesive on packaging tape. The sticky residue left behind by the tape can also be difficult to remove from sensitive surfaces. Therefore, it is advisable to use appropriate sealing methods and materials specifically designed for electronics or appliances. These may include specialized tapes, foam gaskets, or custom-fitted protective covers. It is always recommended to consult the manufacturer's guidelines or seek professional advice when sealing electronics or appliances to ensure proper protection and functionality.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass Mesh Gummed Adhesive Tape Double Side Waterproof

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 roll

- Supply Capability:

- 500000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products