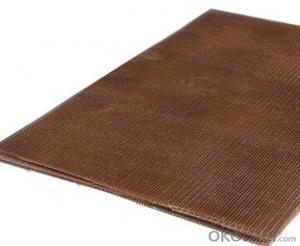

Fiberglass mesh filter

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Fiberglass mesh filter for molten aluminum filtration are designed and woven for the diffusion and filtration of molten aluminum.The molten aluminum is very easy to be oxidated when touch with air.With the use of NX-EFG,the pure molten aluminum is more easy to get during primary melting, foundry casting and scrap recycling.The main type can be the one without coating or Acrylic coating(white color) or with resin coating(yellow color) and non-smoke treatment(black color).

Main Features:

-No contaminate to the molten aluminum

-Cost effective & easy installation

-Reduce turbulence & improve distribution and flow

-Remove oxides and inclusions.

-Excellent stiffness and toughness,good impact resistance

-Well organized grid to ensure fine filtration

Application:

-As the first filtration for primary smelting

-Sand casting,gravity or low pressure die casting

Specification:

Yarn type:Alkali free E-glass

SiO2 contents:58%

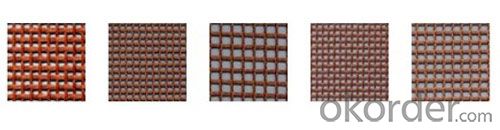

Weave pattern:Leno or plain

Weight:50-400g/m2

Width:Max.2.10m

Length per roll:50/100/150/200/300m or as per request

Mesh size:0.5-2.5mm

Open area:25-65%

Thickness:0.18-35mm

Working temperature:700-850 Degree C

*Mesh size:1.0x1.0mm,1.2x1.2mm,1.5x1.5mm,2.0x2.0mm,2.5x2.5mm.

*Different cut pieces sizes and shapes like cap,tubular,funnel etc. are available upon request.

- Q:What is the filtration accuracy of 50nm ceramic membrane?

- 50nm refers to the nominal pore size, but it does not mean that the holes in the ceramic membrane are 50nm, but the approximate number of holes. The size of the pores may be between 40~60 and 45 to 55nm. Generally introduced, annotated range, you can also own to detect.

- Q:What are the causes of the powder moisture in the ceramic filter?

- Generally, the ceramic filter is used to filter iron powder, and the water content of the filter cake is about 10%.

- Q:The vacuum of ceramic filter is not enough

- The vacuum degree of ceramic filter is about -0.08MPa, if the ceramic filter is less than 0.06MPa, the vacuum is not enough. If the vacuum of ceramic filter is not enough, it will influence the suction effect of ceramic filter (mainly the thickness of filter cake and water content of filter cake).

- Q:Can the ceramic plate filter the hot air?

- Ceramic filter is a new and efficient dehydration equipment. If users find the ceramic filter board surface suction effect is poor, or even do not suck slurry, we should promptly investigate the causes, so as not to affect production efficiency. I hope the following analysis will help you. First, the reasons for the ceramic filter.

- Q:Common troubles of ceramic filter

- Ultrasonic cleaning, ceramic filter plate cleaning is not clean. The main reason is that the power box is faulty, the power supply is burned out, the line is aging, the energy head is burned out, the ultrasonic box is broken down, and the water level in the pulp tank is too low;

- Q:What are the poor filtration effects of vacuum disc filters?

- Under normal circumstances, high vacuum, vacuum suction, high production capacity, filter cake moisture control is good. At present, some ceramic filters are equipped with two or multi-stage vacuum system to obtain almost absolute vacuum, and can reach 0.09 ~ 0.098MPa.

- Q:How many degrees does the ceramic filter melt?

- Spinel is basically over 1600-1700. It's not too acid proof.There are other materials such as silicon nitride. Ceramics can be more than 1300 degrees in temperature. So the material you are using now is unlikely to melt and melt, and you can change it into one of the top materials. Baidu, this stuff is all over the street.

- Q:The use of water glass as beneficiation agent, copper concentrate in the ceramic filter can not filter, how to do?

- As everyone knows, ceramic filter medium is a ceramic filter plate, microporous ceramic filter plate with a lot of distribution from the outside to the inside capillary effect, its mechanism is based on the capillary effect of microporous ceramic filter, filtration, the filtrate (generally refers to water) through these pores under the action of the vacuum suction pump, filter cake is trapped on the surface of the ceramic filter plate.

- Q:Why does not the iron filter of the ceramic filter work?

- You should make it clear that the filter cake has always been dry or suddenly dry, and now how much moisture? Generally, the ceramic filter is used to filter iron powder, and the water content of the filter cake is about 10%.

- Q:What are the reasons for the program alarm of ceramic filter?

- If you say "lean" is the ceramic filter suction when the ceramic filter plate into a cake of thin, high water content, is the ceramic filter for their own reasons, can from the following aspects: the investigation considering this phenomenon is always so recently or just happened, if you have been so, probably because your selection is not suitable for pulp the ceramic filter (such as mud content, fine grain size, ceramic filter plate selection such as inconsistent or unqualified ceramic filter). If this anomaly has occurred recently, it is possible to change the ore condition, and the operation parameters of ceramic filters or the cleaning are not up to standard. You can check the vacuum system (vacuum generally ranges from -0.09 to -0.075MPa), backwashing system (generally refers to the filtered water recoil 0.07 ~ 0.12MPa), acid (HNO3 system standards), ultrasonic system is normal.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass mesh filter

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords