Fiberglass Mesh Fabric Plain Woven Reinforcement

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Fiberglass Mesh Fabric Plain Woven Reinforcement

Fiberglass Mesh Fabric Plain Woven Reinforcement is mainly alkali-resistant fiberglass fabric, use the C /E-glass fiber yarn (main ingredient is a silicate, good chemical stability) through a special weaving technique, then by the anti-alkali and reinforcing agent etc high temperature heat finishing treatments. It's an ideal engineering material in construction and decoration industry.

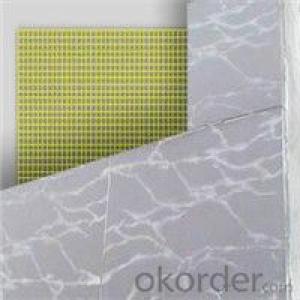

Image of Fiberglass Mesh Fabric Plain Woven Reinforcement

Quick Detail of Fiberglass Mesh Fabric Plain Woven Reinforcement

FOB Price of Fiberglass Mesh Fabric Plain Woven Reinforcement: US $0.21 – 0.32 / Square Meter

MOQ of Fiberglass Mesh Fabric Plain Woven Reinforcement: 5000 Square Meters

Supply Ability of Fiberglass Mesh Fabric Plain Woven Reinforcement: 2000000 Square Meters per Month

Loading Port of Fiberglass Mesh Fabric Plain Woven Reinforcement: CHINA MAIN PORT

Payment Terms of Fiberglass Mesh Fabric Plain Woven Reinforcement: L/C, T/T

Specifications of Fiberglass Mesh Fabric Plain Woven Reinforcement

Fiberglass Mesh Fabric Plain Woven Reinforcement Place of Origin: China (Mainland)

Fiberglass Mesh Fabric Plain Woven Reinforcement Brand Name: CMAX

Fiberglass Mesh Fabric Plain Woven Reinforcement Application: Wall Material, Marble Slab Reinforcement

Fiberglass Mesh Fabric Plain Woven Reinforcement Width: 1M-2M

Fiberglass Mesh Fabric Plain Woven Reinforcement Size: 5*5/ INCH, 4*4/ INCH, 4*5/ INCH

Fiberglass Mesh Fabric Plain Woven Reinforcement Weight: 40gsm to 200gsm

Fiberglass Mesh Fabric Plain Woven Reinforcement Length/ roll: 50m-100m, Special spec can be customized

Fiberglass Mesh Fabric Plain Woven Reinforcement Weave Type: Leno, Plain Woven

Fiberglass Mesh Fabric Plain Woven Reinforcement Yarn Type: C-Glass, E-Glass

Fiberglass Mesh Fabric Plain Woven Reinforcement Alkali Content: Medium Alkali

Fiberglass Mesh Fabric Plain Woven Reinforcement Standing Temperature: 500℃

Packing and Delivery of Fiberglass Mesh Fabric Plain Woven Reinforcement

Package: Fiberglass Mesh Fabric Plain Woven Reinforcement roll wrapped in a shrink bag, then put into containers

Packing Volumes: : 45000-50000m2/ 20FCL, 110000m2/ 40HQ, etc..

Delivery: About 15 days after confirming the order of Fiberglass Mesh Fabric Plain Woven Reinforcement

Application/Usage of Fiberglass Mesh Fabric Plain Woven Reinforcement

A. Wall reinforced material:

Fiberglass wall mesh, GRC wall panels,

EPS insulation with the wall board,

Gypsum board, Bitumen etc

B. Reinforced cement products.

C. Used for Granite, mosaic, marble back mesh etc.

D. Fabric waterproof membrane, asphalt roofing.

E. Framework material for reinforced plastics, rubber products,.

F. Fire board.

G. Grinding wheel base fabric.

H. Road surface geogrid.

I. Construction caulking tape etc.

FAQ of Fiberglass Mesh Fabric Plain Woven Reinforcement

Q: What is Fiberglass Mesh?

Coated Alkali-resistant Fiberglass Mesh cloth is based on C-glass or E-glass woven cloth and treated by alkali-resistance copolymer resin on the surface. The woven cloth is made of fiberglass yarn or roving by means of leno or plain weave. The diameter of elementary fiberglass varies between 9 and 15 micron.

Q: What is the main application of Fiberglass Mesh Fabric Plain Woven Reinforcement?

External thermo insulating composite System (ETICS) & External insulating finish system (EIFS)

External and internal plaster reinforcement

Electrical heating mats

Marble slab reinforcement / Mosaic carrier

Asphalt reinforcement (roof water-proof)

Reinforced lightweight construction boards

Q: What is the storage of Fiberglass Mesh Fabric Plain Woven Reinforcement?

Store rolls in a cool, dry location

Store away from the direct contact with ground or concrete

Store out of direct sunlight

Protect rolls from weather and other damage

Q: What is the guarantee period of Fiberglass Mesh Fabric Plain Woven Reinforcement?

Four years under normal weather conditions and use

Q: What is the Advantage of Fiberglass Mesh Fabric Plain Woven Reinforcement?

A. Good chemical stability: Alkali-resistant, acid-resistant, waterproof, cement erosion-resistant, and other chemicals' corrosion resistant; and strong resin bonding, soluble in styrene.

B. Outstanding craftsmanship include coating enough alkali-resist glue, our coating glue is produced by Germany BASF which can keep 60-80% strength after test in Naoh 28days later, so that guarantee high strength, high tensility, light weight.

C. Our fiberglass yarn is supplied by Jushi Group which is the largest producer of fiberglass yarn in the world like Saint Gobain, it's 20% extra strong strength and beauty surface than normal fiberglass yarn.

D. Strength retention rate> 90%, elongation<1%, the durability of more than 50 years.

E. Good dimensional stability, stiffness, smoothness an difficult to shrink and deformation, good positioning property.

F. Good impact resistance and not easy to be teared

- Q:The difference between alkali resistant mesh fabric emulsion and urine glue 7.5

- The mesh fabric is soft and positioned, and also folded, both of which are the common products of the exterior wall insulation.For positioning glass fiber mesh cloth glue, we do not know is not the use of adhesive to fix, in fact, glass fiber mesh cloth itself with a certain amount of binder, binder general alkali resistant glass fiber mesh is used in milkLiquid coating stereotypes, and no alkaline, usually use urine gum for coating treatment, stereotypes are almost the same effect,The effect of the coating is only too hard, so it is brittle, and sometimes it breaks easily.

- Q:Glass fiber mesh cloth, pure gold pot with what glue out, finished products can be detected, as well as the proportion of glue is how much?

- 1, first of all, from the material, imitation gold pot mesh cloth, its warp is Kim Nabesa, weft is Tonabe Sa, this is called "imitation gold pot" mesh cloth one aspect.2, and then, imitation gold pan mesh cloth looks like the appearance of the gold pan mesh cloth is exactly the same, so it has become imitation gold pot.3, and finally, the quality of imitation gold pan mesh cloth can never be better than the quality of the gold pan mesh cloth, which is also called "imitation gold pot" one of the reasons.

- Q:What is the use of alkali resistant fiberglass mesh cloth on the exterior wall?

- The use of composite plaster mortar of alkali resistant glass fiber cloth, on the one hand, can effectively increase the tensile strength of the protective layer, on the other hand, can effectively disperse stress, can be originally may have wider cracks spread into many smaller cracks, thus forming the crack in. The surface coating material and the amount of coating have important significance to the alkali resistance of glass fiber mesh cloth, and the glass fiber variety has a decisive significance for long-term alkali resistance. In the process of using glass fiber mesh: mesh between lap width not less than 50mm, the negative corner mesh to pressure stubble lap, its width is larger than 50mm, yang angle is greater than or equal to 200mm. In the construction, mesh paving should be smooth, no wrinkles, mortar plumpness reached 100%, at the same time to find and maintain smooth, straight corner square and the verticality of yin and yang.

- Q:What is the difference between alkali resistant fiberglass mesh cloth and high alkali glass fiber mesh cloth?

- Alkali resistance refers to the performance of special glass fiber, while high alkali refers to the composition of glass fiber.Are two completely different concepts.

- Q:How is fiberglass mesh used?

- Brushing the wall latex Putie mesh cloth, mesh cloth to Putie formation, Jiecha overlap should be at least 50MM, to be completely dry after the wall, and then carry out the procedure.

- Q:Slotted walls, seams, seams, tape, or anti mesh cloth?

- Don't spend so much money to buy what tape and mesh cloth, is decorated well, to buy the cheapest dacron, remember to not want that kind of chemical fiber, cotton, cotton for a long time to decay.

- Q:Where is fiberglass mesh better?

- Quality and import gap is not large, but prices are significantly lower. If you do not take the price into consideration, it must be the best of the imports.

- Q:What's the use of fiberglass mesh?

- Main performance and characteristics:1 、 good chemical stability. Alkali resistance, acid resistance, water resistance, cement corrosion resistance, and resistance to other chemical corrosion; and resin adhesion, soluble in styrene and so on.2, high strength, high modulus, light weight.3, good dimensional stability, stiffness and smooth, not easy to deformation, shrinkage of.4 、 good shock resistance. (because of high mesh strength and good toughness)5, mildew change, pest control.6. Fire protection, heat preservation, sound insulation and insulation.

- Q:What is the function of the wall cloth mesh?

- The product has the advantages of stable structure, high strength, good alkali resistance, corrosion resistance, crack resistance, etc., and the enhancement effect is the best, and the construction is simple and easy to do. Mainly used for cement, gypsum, wall, building and other structures to enhance the internal and external surface, crack prevention, is a new type of building materials insulation project.

- Q:What harm does fiberglass mesh have to people?

- Glass fiber can irritate the skin, cause skin irritation, itching, and may cause deeper damage.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass Mesh Fabric Plain Woven Reinforcement

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords