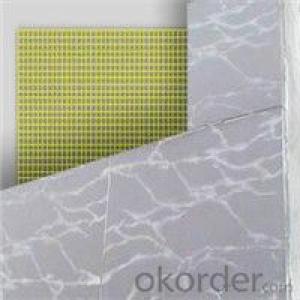

fiberglass mesh cloth with high strength 65g 5*5

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

9

Specifications

reinforcing fiberglass mesh 160g/m2 75g/m2

1. ISO management

2. OEM service

3. Good price

4. Export standard

reinforcing fiberglass mesh 160g/m2 75g/m2

Product Description

Item name: fiberglass mesh fabric for interior wall reinforcement

Usage:partition board reinforcement,wall coating anti-crack,interior decoration angle repair, Dedicated anti-crack, etc.

Building exterior wall thermal insulation material is widely used.

Quality guarrantee:In strict accordance with the export standards,on-time delivery,Welcome to inspection before shipping.

Item Number | Mesh Size (mm) | Finished weight (g/m2) | Tensile StrengthX500px | Content of resin %(≥) | |||

Warp | Weft | Warp | Weft | ||||

CNP10X10-60 | 10 | 10 | 60 | 500 | 650 | 17 | |

CNP4X5-75 | 4 | 5 | 75 | 600 | 650 | 18 | |

CNP5X5-80 | 5 | 5 | 80 | 700 | 850 | 18 | |

CNP5X5-90 | 5 | 5 | 90 | 700 | 1050 | 18 | |

CNP4X4-100 | 4 | 4 | 100 | 750 | 1000 | 18 | |

CNP10X10-100 | 10 | 10 | 100 | 1000 | 1250 | 20 | |

CNP4X5-120 | 4 | 5 | 120 | 1000 | 1300 | 18 | |

CNP5X5-125 | 5 | 5 | 125 | 1200 | 1300 | 18 | |

CNP10X10-125 | 10 | 10 | 125 | 1250 | 1450 | 20 | |

CNP5X5-135 | 5 | 5 | 135 | 1300 | 1400 | 18 | |

CNP4X4-135 | 4 | 4 | 135 | 1000 | 1300 | 18 | |

CNP4X5-140 | 4 | 5 | 140 | 1300 | 1350 | 18 | |

CNP10X10-145 | 10 | 10 | 145 | 1250 | 1700 | 20 | |

CNP5X5-145 | 5 | 5 | 145 | 1400 | 1500 | 18 | |

CNP4X5-150 | 4 | 5 | 150 | 1300 | 1300 | 18 | |

CNP5X5-160 | 5 | 5 | 160 | 1450 | 1600 | 18 | |

CNP4X4-160 | 4 | 4 | 160 | 1550 | 1650 | 18 | |

CNP4X5-165 | 4 | 5 | 165 | 1300 | 1300 | 18 | |

CNP4X4-170 | 4 | 4 | 170 | 1450 | 1700 | 18 | |

CNP4X5-200 | 4 | 5 | 200 | 1500 | 2200 | 18 | |

- Q:The difference between alkali resistant mesh fabric emulsion and urine glue 7.5

- The mesh fabric is soft and positioned, and also folded, both of which are the common products of the exterior wall insulation.For positioning glass fiber mesh cloth glue, we do not know is not the use of adhesive to fix, in fact, glass fiber mesh cloth itself with a certain amount of binder, binder general alkali resistant glass fiber mesh is used in milkLiquid coating stereotypes, and no alkaline, usually use urine gum for coating treatment, stereotypes are almost the same effect,The effect of the coating is only too hard, so it is brittle, and sometimes it breaks easily.

- Q:What is the use of alkali resistant fiberglass mesh cloth on the exterior wall?

- The use of composite plaster mortar of alkali resistant glass fiber cloth, on the one hand, can effectively increase the tensile strength of the protective layer, on the other hand, can effectively disperse stress, can be originally may have wider cracks spread into many smaller cracks, thus forming the crack in. The surface coating material and the amount of coating have important significance to the alkali resistance of glass fiber mesh cloth, and the glass fiber variety has a decisive significance for long-term alkali resistance. In the process of using glass fiber mesh: mesh between lap width not less than 50mm, the negative corner mesh to pressure stubble lap, its width is larger than 50mm, yang angle is greater than or equal to 200mm. In the construction, mesh paving should be smooth, no wrinkles, mortar plumpness reached 100%, at the same time to find and maintain smooth, straight corner square and the verticality of yin and yang.

- Q:Do external insulation with alkali resistant fiberglass mesh cloth, why should the first layer be double or thickened?

- The two layer and the above position can not be reached by human activities, so it is OK to adopt single layer mesh cloth.

- Q:Where is fiberglass mesh better?

- Indeed, fiberglass mesh imports are good. Most of the domestic and imported goods still have a certain gap.

- Q:What is the difference between alkali resistant fiberglass mesh and glass fiber mesh fabric?

- Alkali resistant glass fiber mesh cloth on the alkali or alkali glass fiber woven fabrics based coating formed by the alkali, the product of high strength, good bonding, docile, excellent positioning, widely used in the reinforcement of walls, wall insulation, roofing and other aspects

- Q:What's the use of fiberglass mesh?

- Main performance and characteristics:1 、 good chemical stability. Alkali resistance, acid resistance, water resistance, cement corrosion resistance, and resistance to other chemical corrosion; and resin adhesion, soluble in styrene and so on.2, high strength, high modulus, light weight.3, good dimensional stability, stiffness and smooth, not easy to deformation, shrinkage of.4 、 good shock resistance. (because of high mesh strength and good toughness)5, mildew change, pest control.6. Fire protection, heat preservation, sound insulation and insulation.

- Q:The building is how to choose the external wall thermal insulation material of glass fiber mesh cloth?

- When the heat of the interior passes through the wall mesh, the insulation will be cut off and retained, and when the room temperature falls. The wall of the heat will be released, by adjusting the indoor temperature; in the summer, glass fiber mesh insulation would block the sun's radiation and external heat into the room, so that the indoor situation of "cool", and the ten seasons and pleasant residential Polygonatum and physical skills improved significantly

- Q:What harm does fiberglass mesh have to people?

- Glass fiber can irritate the skin, cause skin irritation, itching, and may cause deeper damage.

- Q:What kind of wall fabric is covered with fiberglass mesh? Do you apply the powder or the powder? Thank you

- The interior powder is usually used at the joint of the wall (there is a mesh fabric specially used for joint, called adhesive tape or joint tape)

- Q:Can indoor glass fiber mesh cloth be stuck with wall tiles?

- Yes, glass fiber mesh is used for roofing, waterproofing and gypsum, marble, mosaic and other wall or plate reinforcement.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

fiberglass mesh cloth with high strength 65g 5*5

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords