Fiberglass Hollow Rod FRP Pultrusion Tube

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 80000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

PRODUCT DESCRIPTION

FRP Fitting, a wide range of fittings as elbows, reducers, tees, caps, flanges etc. is available.

Fittings are manufactured by the hand lay-up, contact molding and spray-up process. In hand lay-up and contact

molding processes veil and alternate layers of mat and woven roving saturated with resin are applied on the mold. In spray-up process continuous strand roving is fed through a chopper gun, combined with catalyzed resin, and sprayed onto the mould surface.

FEATURES

1. High anti-corrosion capability, long designed service time of 20 years;

2. Good hydraulic property, smooth inner surface with absolute roughness of 0.01mm, which is far less than that of carbon steel pipe or cast iron pipe;

3. Lightweight and facility to install and transport;

4. High specific intensity and reliable mechanical performance;

5. Low thermo-conductivity and small thermo-stress, which are allowed to be used in various conditions: exposed buried or suspended, in ocean or in deserts, freezing or humid;

6. Less joints and rapid assembly design: According to concrete engineering conditions, there are a several ways of connection designed for clients to choose, which include Adhesive-bonded Plug Joint, Adhesive-bonded End-to-end Joint, Flange Joint, Plug Joint with O-ring Gasket(with key-lock) and Thread Joint etc.

7. Good electrical insulation

8. Not rust, rot or corrode, not permeate, and without consequent pollution;

9. Anti-furring and vermiculate resistance;

TECHNICAL DATA

Stiffness | SN3750 | SN5000 | SN10000 | ||||||

Pressure | 0.25 | 0.6 | 1.0 | 0.25 | 0.6 | 1.0 | 0.25 | 0.6 | 1.0 |

400 | 6.1 | 6.1 | 5.9 | 6.7 | 6.7 | 6.4 | 8.1 | 8.1 | 7.87 |

500 | 7.2 | 7.2 | 7.1 | 8 | 8 | 7.7 | 11.4 | 9.6 | 9.4 |

600 | 8.7 | 8.3 | 8.3 | 9.6 | 9.6 | 9.2 | 12.1 | 11.7 | 11 |

700 | 9.7 | 9.7 | 9.4 | 11.2 | 11.2 | 10.4 | 13.8 | 13.2 | 12.5 |

800 | 11.6 | 11.3 | 10.6 | 12.8 | 12.5 | 11.7 | 15.5 | 15 | 14.2 |

900 | 13.4 | 12.5 | 11.7 | 14.8 | 13.8 | 12.9 | 19.3 | 16.4 | 15.8 |

1000 | 14.6 | 13.7 | 13 | 16.2 | 15.1 | 14.4 | 20.7 | 18 | 17.3 |

1100 | 16.1 | 14.9 | 14.2 | 17.9 | 16.5 | 15.6 | 23 | 19.8 | 18.9 |

1200 | 17.2 | 16.1 | 15.4 | 19.6 | 17.9 | 16.9 | 24.7 | 21.5 | 20.6 |

1400 | 20.4 | 18.4 | 17.7 | 22.7 | 20.5 | 19.5 | 29.2 | 24.8 | 23.8 |

1500 | 22 | 19.9 | 18.7 | 24.4 | 22.1 | 20.7 | 31.4 | 26.3 | 25.3 |

1600 | 23.6 | 21.2 | 20 | 26.2 | 23.4 | 22 | 33.7 | 28.2 | 26.9 |

1800 | 26.3 | 23.5 | 22.4 | 29.2 | 26.1 | 24.7 | 36.4 | 31.6 | 30.3 |

2000 | 27.4 | 25.4 | 23.4 | 35 | 32.4 | 29.6 | 44.7 | 37.3 | 36.1 |

2200 | 29.7 | 27.6 | 25.3 | 37.8 | 35.3 | 32.6 | 48.7 | 41.5 | 40.4 |

2400 | 32.6 | 30.3 | 28.4 | 41.8 | 38.8 | 34.6 | 53.4 | 44.6 | 42.8 |

2600 | 36.3 | 33.5 | 31.5 | 45.2 | 40.5 | 35.4 | 55.8 | 47.2 | 45.6 |

2800 | 39.6 | 36.0 | 34 | 49.4 | 45.1 | 42 | 62 | 53 | 51 |

3000 | 41.0 | 38.1 | 36.2 | 52 | 47 | 45.3 | 67 | 58.2 | 54 |

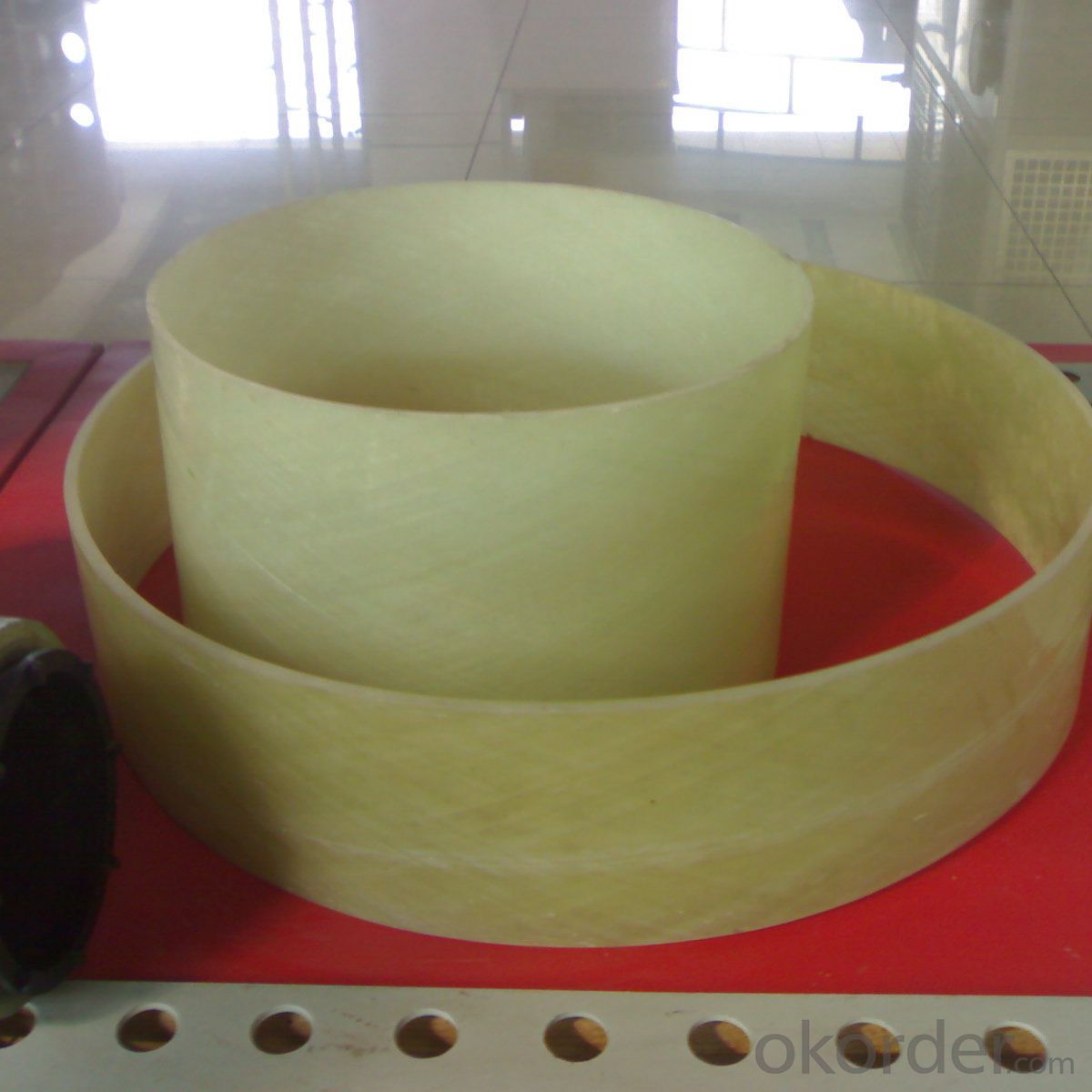

PICTURES

- Q:What is the compressive strength of all kinds of FRP materials?

- Good corrosion resistance, no impact on water quality: FRP pipe can resist acid, alkali, salt, sea water, untreated sewage, corrosive soil or groundwater and many chemical fluids erosion. The service life of the pipe is longer than that of the traditional pipe, and the designed service life is more than 50 years. Of fiberglassreinforcedplastic pipe, is more used in municipal, city pipeline network, due to its non-toxic, tasteless, no rust, no two pollution on water quality, no corrosion, greatly prolong the service life, convenient installation and other advantages, therefore, by the water supply and drainage industry welcome.

- Q:Why more and more people choose FRP pipe?

- And the price ratio of FRP pipe is not much cheaper, and although the hardness of concrete pipe although FRP pipe to be hard, but the toughness and tensile strength is poor, the pressure is not good, and the cost is expensive, because more and more people use glass steel, and the price is expensive, with longer life.

- Q:What are the materials used in smoke exhaust pipes?

- In the production of the coal mine exhaust pipe is indispensable, in underground work, because from the ground, the air is not easy to reach, easy to accumulate large amounts of methane gas, these gases will need ventilation pipe timely transferred to the ground to prevent the explosion in the coal mine ventilation pipe, the material is generally iron and plastic.

- Q:Uneven settlement of the foundation, can lead to glass fiber reinforced plastic underground water pipes burst, what is the principle?

- Dislocation will cause the pipe to burst. The pressure is different, and the pipe will burst

- Q:What are the advantages of glass fiber reinforced plastic sand pipe than HDPE pipe?

- Both have their merits, but it depends on their choice!

- Q:What is fiberglass communication tube?

- Glass fiber reinforced plastic communication tube is a kind of light, high strength, corrosion resistant and burr free metal pipe. It is mainly used for protecting cables and cables.

- Q:Would like to ask about the plastic lined steel pipe, steel pipe, glass steel skeleton, the advantages and disadvantages of each ceramic pipe, to know a friend told, very grateful!

- Plastic lined steel pipe of strong corrosion resistance, heavy quality, need to be made, on-site installation, if the size deviation cannot be installed. The price is more than 5 times more expensive than that of FRP

- Q:A basic overview of FRP pipes

- FRP pipes are used in petroleum, chemical and drainage industries. Glass fiber reinforced plastic pipeline production in China has developed rapidly, and the quantity has been increasing year by year, and the scope of application and departments are becoming wider and wider.

- Q:What can be done to solve the leakage of FRP pipe?

- The method of mending is hand paste. The stones must be taken away so that the pipes are restored to their original shape. If you can get into the pipe, polish it first and repair the lining.

- Q:What kind of material is the pipe of the pipe that installs the pressure transmitter of GRP conduit? Is it fiberglass or carbon steel?

- This depends on what your medium is, the general food industry requires stainless steel, but the medium contains acidic substances, stainless steel is better than FRP corrosion resistance

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass Hollow Rod FRP Pultrusion Tube

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 80000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords