Fiberglass Geogrid Woven with Geotexitle

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid Woven with Geotexitle

Description Of Fiberglass Geogrid Woven with Geotexitle:

1. A kind of planar mesh material using alkali-free fiberglass yarn as base body and

then coated with high quality modified asphalt.

2. Warp knitted with oriental structure which gives full play of yarn strength and improves its mechanical property to make the product high tensile, tearing and creep-resistant.

3. Coated with asphalt making full protection of the fiberglass matrix and greatly

improving its wear and shear resistance.

4. Having a good performance in pavement strengthening, track cracking and solving

difficulties of strengthening the bituminous pavement.

Main Features of Fiberglass Geogrid Woven with Geotexitle:

1. Light weight, high tensile strength, high modulus, low elongation and good toughness.

2. Corrosion resistance, no long-term creep, long life span.

3. Good physical and chemical stability and good thermal stability.

4. Resistant to fatigue cracking, high-temperature track and low temperature shrinkage cracking.

5. Delaying and decreasing crack reflection.

Specifications of Fiberglass Geogrid Woven with Geotexitle:

Tensile Strength (KN) | Warp | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >200 |

Weft | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >120 | |

Elongation(%) | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | |

Mesh Size(mm) | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | |

Elastic Modulus | 76 | 76 | 76 | 76 | 76 | 76 | 76 | 76 | |

Width(m) | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | |

Length(m) | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | |

Temperature Resistant(℃) | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | |

Resin Content (%) | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | |

Glue Type | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | |

Applications of Fiberglass Geogrid Woven with Geotexitle:

1. Maintenance of old asphalt road reinforcement of asphalt pavement.

2. Converting old cement concrete road into composite road.

3. Restraining reflection cracking caused by block shrinkage.

4. Preventing and controlling the cracking caused by new and old combination and uneven settlement.

5. Road extension.

6. Reinforcement of soft soil foundation and overall strength of roadbed.

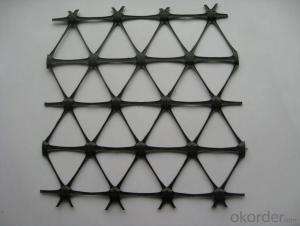

IMages of Fiberglass Geogrid Woven with Geotexitle:

FAQ of Fiberglass Geogrid Woven with Geotexitle:

1. What are we supplying?

We are specialized in producing Geosynthetic materials, like Geogrid Series, HDPE Geocell, Geonet, Geotextile, Geomat, Tri Denmensional Composite Grainage Geonet, and Geomembrane Series.

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q:Are geogrids suitable for reinforcing embankments?

- Yes, geogrids are suitable for reinforcing embankments. Geogrids are made of strong materials such as polyester or polypropylene and are designed to provide stability and strength to soil structures. They can be used to reinforce embankments by distributing load more evenly, reducing soil movement, and improving overall stability. Geogrids also help prevent erosion and increase the overall lifespan of embankments.

- Q:How do geogrids improve the performance of geotextile sediment control tubes?

- Geogrids improve the performance of geotextile sediment control tubes by providing additional strength and stability. They enhance the tube's ability to retain sediment by preventing internal erosion and maintaining its shape under external forces. This combination of geogrids and geotextiles helps to effectively control erosion and sedimentation in various applications.

- Q:Why steel plastic geogrid in the test, will choose to peel out a single wire test? What are the causes and sources of this method

- Peel out because of the more intuitive understanding of the strength of the tensile strength and extension of the length of the wire wrapped in order to protect the steel wire does not rust.

- Q:Are there any limitations or disadvantages of using geogrids?

- Yes, there are some limitations and disadvantages of using geogrids. 1. Cost: Geogrids can be relatively expensive compared to other soil reinforcement methods. The cost of materials and installation can sometimes be prohibitive, especially for large-scale projects. 2. Limited Applications: Geogrids are not suitable for all types of soil conditions. They are most effective in granular soils, but their performance in cohesive soils or unstable slopes may be limited. 3. Installation Challenges: Proper installation of geogrids requires specific expertise and equipment. If not installed correctly, their effectiveness can be reduced, leading to potential failure or performance issues. 4. Longevity: The long-term durability of geogrids can vary depending on factors such as exposure to environmental conditions, chemical degradation, and mechanical damage. In some cases, they may require regular maintenance or replacement to ensure continued effectiveness. 5. Compatibility: Geogrids may not always be compatible with certain construction materials or methods. It is important to consider their compatibility with other materials used in the project to avoid any adverse effects on performance. Despite these limitations, geogrids are still widely used in various geotechnical applications due to their ability to improve soil stability and enhance the performance of structures.

- Q:Can geogrids be used in stabilization of riverbanks?

- Yes, geogrids can be used in the stabilization of riverbanks. Geogrids are often used to reinforce and stabilize soil in various applications, including erosion control along riverbanks. Their high tensile strength and ability to distribute loads make them effective in preventing soil erosion and maintaining the stability of riverbanks.

- Q:How do geogrids improve the performance of pavements?

- Geogrids improve the performance of pavements by providing reinforcement and stabilization. They help distribute the load more evenly, reducing stress and preventing cracks and rutting. Geogrids also enhance the pavement's tensile strength, increasing its overall durability and lifespan.

- Q:Do geogrids increase the bearing capacity of soil?

- Yes, geogrids can increase the bearing capacity of soil. Geogrids are materials made of polymers or metals that are used to reinforce soil. They help distribute the load more evenly, reducing the stress on the soil and increasing its ability to bear heavier loads.

- Q:What are the benefits of using geogrids in construction?

- Geogrids offer several benefits in construction, including improved stability and reinforcement of soil, increased load-bearing capacity, reduced soil erosion, enhanced drainage, and cost-effectiveness. They act as a strong reinforcement material, distributing loads evenly and preventing soil movement. Geogrids also provide long-term durability, resistance to harsh environmental conditions, and versatility in various construction projects. Overall, the use of geogrids can significantly enhance the performance and longevity of structures while minimizing maintenance requirements.

- Q:Are geogrids suitable for reinforcement of soft soils?

- Yes, geogrids are suitable for the reinforcement of soft soils. Geogrids are specifically designed to improve the stability and strength of weak soils by distributing load and providing tensile strength. They effectively restrain lateral movement and increase the bearing capacity of soft soils, making them a reliable solution for reinforcement in such conditions.

- Q:Geogrid construction must be folded back 2m wrapped in compacted packing on it?

- Edit this section of geogrid construction notesPaved geogrid should be smooth, paving layer after acceptance, to prevent longitudinal askew phenomenon, according to the width of paving layer or draw white thread, you can start paving, and then use the end of the nail fixed grid (nail 8, per meter wide uniform fixed distance) well, after the end of the fixed grid, with the paving machine will grill slowly pulled forward each shop, shop 10 meters long artificial tightening and straightening once, until a volume grating puwan, put the next volume, operation with a roll of puwan with roller 6T-10T from the starting point to begin the direction of rolling over, (steel rolling as road paving in the surface layer and the leveling layer, the machine is appropriate; such as grid laid directly on the concrete pavement, with the roller roller is appropriate) ground shop: Volume long unit as the laying of the long, the grid should be covered the long shop Full, then the overall check a paving quality, and then paving the next section, the next section of paving, grille and grille can be used lap length 10-15CM, and fixed with nails or wedge to shop in second, to the direction followed by analogy with operating requirements.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass Geogrid Woven with Geotexitle

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords