Fiberglass Geogrid with Bitumen Coated for Base Stabilization

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid with Bitumen Coated for Base Stabilization

Description Of Fiberglass Geogrid with Bitumen Coated for Base Stabilization:

1. A kind of planar mesh material using alkali-free fiberglass yarn as base body and

then coated with high quality modified asphalt.

2. Warp knitted with oriental structure which gives full play of yarn strength and improves its mechanical property to make the product high tensile, tearing and creep-resistant.

3. Coated with asphalt making full protection of the fiberglass matrix and greatly

improving its wear and shear resistance.

4. Having a good performance in pavement strengthening, track cracking and solving

difficulties of strengthening the bituminous pavement.

Main Features of Fiberglass Geogrid with Bitumen Coated for Base Stabilization:

1. Light weight, high tensile strength, high modulus, low elongation and good toughness.

2. Corrosion resistance, no long-term creep, long life span.

3. Good physical and chemical stability and good thermal stability.

4. Resistant to fatigue cracking, high-temperature track and low temperature shrinkage cracking.

5. Delaying and decreasing crack reflection.

Specifications of Fiberglass Geogrid with Bitumen Coated for Base Stabilization:

Tensile Strength (KN) | Warp | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >200 |

Weft | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >120 | |

Elongation(%) | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | |

Mesh Size(mm) | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | |

Elastic Modulus | 76 | 76 | 76 | 76 | 76 | 76 | 76 | 76 | |

Width(m) | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | |

Length(m) | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | |

Temperature Resistant(℃) | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | |

Resin Content (%) | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | |

Glue Type | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | |

Applications of Fiberglass Geogrid with Bitumen Coated for Base Stabilization:

1. Maintenance of old asphalt road reinforcement of asphalt pavement.

2. Converting old cement concrete road into composite road.

3. Restraining reflection cracking caused by block shrinkage.

4. Preventing and controlling the cracking caused by new and old combination and uneven settlement.

5. Road extension.

6. Reinforcement of soft soil foundation and overall strength of roadbed.

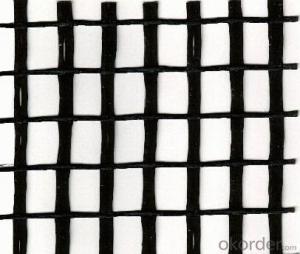

IMages of Fiberglass Geogrid with Bitumen Coated for Base Stabilization:

FAQ of Fiberglass Geogrid with Bitumen Coated for Base Stabilization:

1. What are we supplying?

We are specialized in producing Geosynthetic materials, like Geogrid Series, HDPE Geocell, Geonet, Geotextile, Geomat, Tri Denmensional Composite Grainage Geonet, and Geomembrane Series.

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q:How do geogrids help in reducing soil erosion on slopes?

- Geogrids help in reducing soil erosion on slopes by providing reinforcement and stability to the soil. They are placed within the soil and act as a support system, preventing the movement of soil particles downhill. This reinforcement helps to distribute the loads and stresses evenly, reducing the risk of soil erosion caused by water flow or gravity. Additionally, geogrids increase the shear strength of the soil, making it more resistant to erosion and slope failures.

- Q:Are geogrids resistant to hydrostatic pressure?

- Yes, geogrids are generally resistant to hydrostatic pressure. They are designed to provide reinforcement and stability in soil and can withstand the pressure exerted by water or other liquids.

- Q:How do geogrids help in reducing the environmental impact of construction?

- Geogrids help in reducing the environmental impact of construction by providing soil stabilization and reinforcement, reducing the need for excessive excavation and material usage. This results in minimized disturbance to natural habitats, reduced waste generation, and lower carbon emissions, ultimately promoting sustainable construction practices.

- Q:Are geogrids resistant to chemical leaching?

- Yes, geogrids are generally resistant to chemical leaching. Geogrids are typically made from high-density polyethylene (HDPE) or other chemically inert materials, which makes them highly resistant to chemical leaching. This resistance helps maintain the structural integrity and long-term performance of geogrids in various applications, including soil stabilization, erosion control, and reinforcement projects.

- Q:How do geogrids help in reducing construction material consumption?

- Geogrids help in reducing construction material consumption by providing reinforcement to the soil, allowing for the use of thinner layers of construction materials such as asphalt or concrete. This reduces the overall amount of material required for the project, resulting in cost savings and environmental benefits. Additionally, geogrids help distribute loads more evenly, preventing excessive settlement and reducing the need for additional materials to address potential issues.

- Q:Peel force mainly in the size of raw materials

- The tensile strength of the welded joints!

- Q:What are the advantages of using geogrids in ground improvement for load transfer platforms?

- Geogrids offer several advantages in ground improvement for load transfer platforms. Firstly, they provide enhanced stability by distributing load forces across a wider area, reducing the risk of settlement or failure. Secondly, geogrids increase the bearing capacity of the soil, allowing for the construction of heavier structures or equipment. Additionally, these grids improve soil confinement, preventing the lateral movement of soil particles and reducing the potential for erosion. Moreover, geogrids are easy to install and can be cost-effective compared to alternative methods, making them a preferred choice for ground improvement projects.

- Q:How to connect two-way geogrid

- Transverse 10cm overlap with plastic tape binding on the grid

- Q:What are the typical applications of geogrids?

- Geogrids are commonly used in a variety of applications, including soil stabilization, reinforcement of retaining walls, slope reinforcement, and erosion control. They are also utilized in road construction, landfills, and mining operations. Geogrids help to improve the strength and stability of soil and other materials, making them an essential component in various civil engineering projects.

- Q:What are the long-term maintenance requirements for geogrid-reinforced structures?

- The long-term maintenance requirements for geogrid-reinforced structures typically involve periodic inspections to ensure the integrity and stability of the structure. This may include monitoring for signs of erosion, settlement, or damage to the geogrid or surrounding soil. Additionally, regular maintenance activities such as vegetation control, sediment removal, and drainage management may be necessary to prevent potential issues and ensure the long-term performance of the reinforced structure.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass Geogrid with Bitumen Coated for Base Stabilization

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords