Fiberglass Geogrid Manufacturer with Asphalt Pavement

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid Manufacturer with Asphalt Pavement

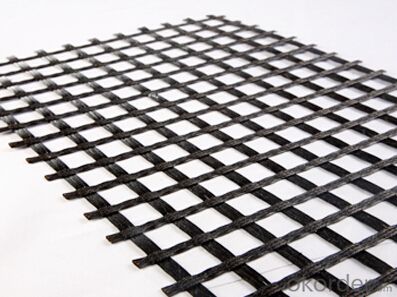

Description Of Fiberglass Geogrid Manufacturer with Asphalt Pavement:

Fiberglass geogrid is a kind of new favorable earthwork base material to strengthen the road surface and roadbed.This product is made by weaving and covering fiberglass filament. It is featured by high vertical and horizontal tensile strength, low unit extension, high flexibility, and favorable high and low temperature resistance.The products after surface covering own the favorable property of alkali resistance and aging resistance. It is used widely to increase the asphalt road surface, concrete road and roadbed (both soft and hard road surfaces). Compared with the traditional road surface, it reduces the cost, prolong the service life, and avoid the reflection road crackle. This product is also used to strengthen the soft land, such as railway, airport, irrigation work, and dyke, etc, and the roadbed.

Main Features of Fiberglass Geogrid Manufacturer with Asphalt Pavement:

1.High tensile strength, low elongation.

2.No long-term creep: the product can keep for a long time performance.

3.Thermal stability: fiber glass melting temperature above 1000 ℃.

4.The compatibility with asphalt.

5.Physical and chemical stability.

Specifications of Fiberglass Geogrid Manufacturer with Asphalt Pavement:

Tensile Strength (KN) | Warp | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >200 |

Weft | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >120 | |

Elongation(%) | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | |

Mesh Size(mm) | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | |

Elastic Modulus | 76 | 76 | 76 | 76 | 76 | 76 | 76 | 76 | |

Width(m) | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | |

Length(m) | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | |

Temperature Resistant(℃) | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | |

Resin Content (%) | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | |

Glue Type | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | |

Applications of Fiberglass Geogrid Manufacturer with Asphalt Pavement:

Strengthen bitumen concrete roadway and reduce and prevent various kinds of reflection gaps on roadway.

1. Maintenance of old asphalt road reinforcement of asphalt pavement.

2. Converting old cement concrete road into composite road.

3. Restraining reflection cracking caused by block shrinkage.

4. Preventing and controlling the cracking caused by new and old combination and uneven settlement.

5. Road extension.

6. Reinforcement of soft soil foundation and overall strength of roadbed.

IMages of Fiberglass Geogrid Manufacturer with Asphalt Pavement:

FAQ of Fiberglass Geogrid Manufacturer with Asphalt Pavement:

1. What are we supplying?

We are specialized in producing Geosynthetic materials, like Geogrid Series, HDPE Geocell, Geonet, Geotextile, Geomat, Tri Denmensional Composite Grainage Geonet, and Geomembrane Series.

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q:What are the factors that influence the design and selection of geogrids for reinforcement?

- There are several factors that influence the design and selection of geogrids for reinforcement. These include the type and characteristics of the soil, the specific application or project requirements, the anticipated loads or stresses on the geogrid, the desired design life and durability, and cost considerations. Additionally, factors such as installation conditions, site constraints, and environmental conditions may also play a role in determining the appropriate geogrid design and selection.

- Q:300 grams of geotextiles a square meter

- Geotextile is a kind of new material geosynthetics, the product is cloth, the general width of 4-6 meters, the length of 50-100 M. Geotextiles are divided into nonwoven geotextiles and nonwoven geotextiles.Ordinary 2 or so

- Q:What is the difference between bidirectional geogrid and unidirectional high strength geogrid

- The uniaxial geogrid is uniform holes in the polymer extrusion molding, and then heated and shaped mesh material, according to the different raw materials can be divided into one-way one-way polyethylene polypropylene geogrid, geogrid

- Q:The effect of steel and plastic grille in steel and plastic grille

- 1 plastic steel plastic grille used to increase the bearing capacity of the road (ground), Yan Changlu (ground) based service life.2 plastic steel plastic grille used to prevent road (ground) surface collapse or crack, keep the ground beautiful and tidy.

- Q:Are geogrids suitable for reinforcement of soft subgrades?

- Yes, geogrids are suitable for reinforcement of soft subgrades. Geogrids are specifically designed to enhance the stability and strength of weak soils, such as soft subgrades. By distributing the load and improving soil confinement, geogrids can effectively reduce settlement and improve the overall performance of the subgrade.

- Q:Can geogrids be used in erosion control applications on steep slopes?

- Yes, geogrids can be used in erosion control applications on steep slopes. Geogrids are often used to reinforce soil and prevent erosion by providing stability and support to the slope. They can effectively distribute loads and reduce the risk of slope failure, making them suitable for erosion control on steep slopes.

- Q:What kind of material is the geogrid in the quota

- Geogrid is made of polypropylene,

- Q:Where is the geogrid used?

- Look at where you are not only to prevent the collapse of fiberglass also prevent asphalt cracking! The other one and the same

- Q:How do geogrids improve the performance of mechanically stabilized slopes in clayey soils?

- Geogrids improve the performance of mechanically stabilized slopes in clayey soils by providing additional reinforcement and enhancing the overall stability of the slope. They help distribute the loads more evenly, reducing the potential for soil erosion and slope failures. Additionally, geogrids increase the shear strength of the clayey soil, preventing excessive deformation and ensuring long-term stability of the slope.

- Q:What are the benefits of using geogrids in construction?

- Geogrids offer several benefits in construction, including improved stability and reinforcement of soil, increased load-bearing capacity, reduced soil erosion, enhanced drainage, and cost-effectiveness. They act as a strong reinforcement material, distributing loads evenly and preventing soil movement. Geogrids also provide long-term durability, resistance to harsh environmental conditions, and versatility in various construction projects. Overall, the use of geogrids can significantly enhance the performance and longevity of structures while minimizing maintenance requirements.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass Geogrid Manufacturer with Asphalt Pavement

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords