Fiberglass Geogrid Manufacturer for Airport Infrastructure Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid Manufacturer for Airport Infrastructure Construction

Description Of Fiberglass Geogrid Manufacturer for Airport Infrastructure Construction:

Fiberglass geogrid is a kind of new favorable earthwork base material to strengthen the road surface and roadbed.This product is made by weaving and covering fiberglass filament. It is featured by high vertical and horizontal tensile strength, low unit extension, high flexibility, and favorable high and low temperature resistance.The products after surface covering own the favorable property of alkali resistance and aging resistance. It is used widely to increase the asphalt road surface, concrete road and roadbed (both soft and hard road surfaces). Compared with the traditional road surface, it reduces the cost, prolong the service life, and avoid the reflection road crackle. This product is also used to strengthen the soft land, such as railway, airport, irrigation work, and dyke, etc, and the roadbed.

Main Features of Fiberglass Geogrid Manufacturer for Airport Infrastructure Construction:

1.High tensile strength, low elongation.

2.No long-term creep: the product can keep for a long time performance.

3.Thermal stability: fiber glass melting temperature above 1000 ℃.

4.The compatibility with asphalt.

5.Physical and chemical stability.

Specifications of Fiberglass Geogrid Manufacturer for Airport Infrastructure Construction:

Tensile Strength (KN) | Warp | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >200 |

Weft | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >120 | |

Elongation(%) | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | |

Mesh Size(mm) | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | |

Elastic Modulus | 76 | 76 | 76 | 76 | 76 | 76 | 76 | 76 | |

Width(m) | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | |

Length(m) | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | |

Temperature Resistant(℃) | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | |

Resin Content (%) | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | |

Glue Type | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | |

Applications of Fiberglass Geogrid Manufacturer for Airport Infrastructure Construction:

Strengthen bitumen concrete roadway and reduce and prevent various kinds of reflection gaps on roadway.

1. Maintenance of old asphalt road reinforcement of asphalt pavement.

2. Converting old cement concrete road into composite road.

3. Restraining reflection cracking caused by block shrinkage.

4. Preventing and controlling the cracking caused by new and old combination and uneven settlement.

5. Road extension.

6. Reinforcement of soft soil foundation and overall strength of roadbed.

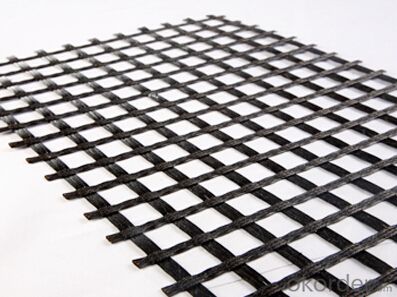

IMages of Fiberglass Geogrid Manufacturer for Airport Infrastructure Construction:

FAQ of Fiberglass Geogrid Manufacturer for Airport Infrastructure Construction:

1. What are we supplying?

We are specialized in producing Geosynthetic materials, like Geogrid Series, HDPE Geocell, Geonet, Geotextile, Geomat, Tri Denmensional Composite Grainage Geonet, and Geomembrane Series.

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q:What is the action mechanism of OKorder geogrid

- Glass fiber geogrid / glassgrid mechanism of reflective cracking is due to the old concrete surface layer in the vicinity of the joint or crack of large displacement caused by the asphalt overlay above appear stress concentration caused by the. Glass fiber geogrid has been developed rapidly in recent years, and is widely used in asphalt pavement, especially used in asphalt overlay to reduce reflection cracks. Texas Traffic College of AM University in Canada with its unique overlay tester of glass fiber geogrid reinforced cover did a lot of tests and experiments show that the reinforced asphalt specimen cracking resistance than the unreinforced specimens two times. Wollongong Municipal Bureau of New South Wales, Australia has conducted on-site tests of glass fiber geogrid, PP geogrid, geotextile and thickness of asphalt concrete surface layer of reflection crack control products, the conclusion is glass fiber geogrid laying convenience, control effect of reflection crack is the most significant, and the cost is moderate. Therefore we should promote the application. Due to the reinforcement effect of glass fiber geogrid on asphalt overlay, so it can be in the premise of effective control of reflection cracks, reduce the asphalt overlay thickness (with and without laying fiberglass geogrid, compared) reduce the cost, and achieved good economic benefit.

- Q:How to distinguish the vertical and horizontal geogrid

- Because the normal use of the vertical and horizontal is the same

- Q:Geosynthetic materials for flood control materials

- Geosynthetics can be divided into geotextile, geomembrane and geotextile composite materials, special geotechnical materials 4 categories: fabric is a kind of porous material, with polypropylene, polyester and nylon and other synthetic fiber materials, according to the production method can be divided into shape, fabric two other non woven. The fabric style is to use a series of single chain according to a certain way woven, generally by the orthogonal warp and weft two group fiber woven fabric; non plastic geotextile is made of short fiber and long fiber directional or random order, by acupuncture or thermal bonding, chemical bonding, the biggest characteristic the strength is no obvious direction, so its use is wide.The aging rate of geotextiles is closely related to the intensity, temperature, humidity, the type and color of the raw materials, the structure of the fabric and the environmental conditions.

- Q:Can geogrids be used in retaining walls for waterfront parks?

- Yes, geogrids can be used in retaining walls for waterfront parks. Geogrids provide reinforcement and stability to the soil, preventing erosion and maintaining the integrity of the retaining wall. They are commonly used in such applications to enhance the strength and durability of retaining walls in waterfront parks.

- Q:What is the difference between gsl30-hdpe geogrid and 30*30kn/m?

- (see description brochure) application of geogrid 2, geogrid can improve the bearing capacity of the foundation (generally can raise more than 40%), increase the diffusion angle, so that the grid filling load diffusion angle increased to 50 from an average of 38 degrees; uneven settlement control, delaying the sedimentation rate; at the same time the role of axial loading and achieve the same effect, can be reduced by 30% - 40% of the thickness of the reinforced embankment, geogrid, traffic volume as the thickness of the Lujikeduo bearing more than 3.5 times. As a reinforced material of reinforced retaining wall and steep slope, the unidirectional geogrid is not only safe and economical, but also because of its special mesh size, the surface of the reinforced structure is easy to be green. 3, grille appearance

- Q:Do geogrids require any maintenance?

- Yes, geogrids generally do not require any maintenance once they are properly installed. They are designed to be durable and resistant to environmental factors, reducing the need for regular maintenance.

- Q:What are the benefits of using geogrids in pavement construction?

- There are several benefits of using geogrids in pavement construction. Firstly, geogrids enhance the pavement's structural integrity by providing additional tensile strength. This helps to distribute loads more evenly, reducing the risk of cracking or rutting. Secondly, geogrids improve the pavement's durability and lifespan by resisting the effects of fatigue and aging. They can also help to reduce maintenance costs over time. Additionally, geogrids aid in preventing reflective cracking, which occurs when cracks from the underlying pavement transfer to the surface. By reinforcing the pavement layers, geogrids minimize the likelihood of reflective cracking, resulting in a smoother and safer road surface.

- Q:What are the specifications of fiberglass geogrid for Asphalt Pavement

- The use of asphalt pavement can only use fiberglass grille, the other are used on the top of the embankment

- Q:What are the design considerations for geogrid-reinforced pavements?

- Design considerations for geogrid-reinforced pavements include the selection and placement of geogrid materials, determining the appropriate grid spacing and orientation, considering loading conditions and traffic loads, evaluating soil properties and subgrade stability, and ensuring proper installation and construction techniques. Additionally, factors such as climate, drainage, and environmental conditions need to be taken into account to ensure the long-term performance and durability of geogrid-reinforced pavements.

- Q:Can geogrids be used in reinforcement of underground parking structures?

- Yes, geogrids can be used in the reinforcement of underground parking structures. Geogrids are commonly used in civil engineering projects to improve soil stability and provide structural support. In underground parking structures, geogrids can be installed to reinforce the soil, distribute loads, and reduce the potential for soil settlement and structural failure. This helps to enhance the overall stability and longevity of the parking structure.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass Geogrid Manufacturer for Airport Infrastructure Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords