Fiberglass FRP Roofing Sheet of China Best

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

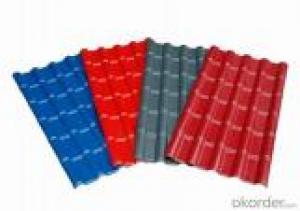

Specifications of China Best Fiberglass FRP Roofing Sheet

FRP Sheet made by serial machinery of FRP sheet have the advantages of smooth surface, even thickness, high impact strength, good weather resistance as well as high productivity. It is the best materials for the surface panels of top grade refrigeration vehicles for its excellent properties of heat and moisture insulaiton.

Thickness:0.8mm、1.0mm、1.2mm、1.5mm、2.0mm、2.5mm、3.0mm;

Width:1000mm、1200mm;

Color:Clear/Lake Blue/Sky Blue/Light Green/ Opal;

Length:30m/rolling

Applications of China Best Fiberglass FRP Roofing Sheet

They are applied to steel structure workshops, warehouses, weather sheds, car parks, weather corridors, lighting sheds, sun sheds,

greenhouses, etc. They are the ideal materials for the choices of enterprises and institutions.

The necessary characters of high quality FRP Corrugated Lighting Sheet:

1. small air bibbles

2. no bubbles

3. anti-aging resin

4. high property upper film(or gelatum)

5. high quality non-alkali fiber-glass

6. consistent high light transmission

7. high chemistry corrosion resistance

8. high anti-ultraviolet property

9. even thickness

Package& Delivery of China Best Fiberglass FRP Roofing Sheet

Wooden pallet,according to custom requires.

Properties of China Best Fiberglass FRP Roofing Sheet

Light transmission

The light transmission of FRP Corrugated Lighting Sheet is between 60-85%. Light through FRP lighting sheet scatters and is mild. It will not form a light band so as to make the indoor brighter.

Weather resistance

The 23μm anti-aging film from Dupont covering on the surface of FRP sheet improves its property of weather resistance. The anti- ultraviolet adsorbing agent mixing in the raw materials absorbs 99.9% of ultraviolet ray of the visible light transmitted through the FRP sheets.This UV protection will help to prevent the dissolution and discoloration of the materials. The unique technology used in FRP Corrugated Lighting Sheet makes the life span of the sheet up to over 15 years, probably 20 years ( a ten-year warranty is supplied).

Impact resistance

The strengthening fiber-glass materials criss-cross the structure of the products,which helps to improve the impact resistance of FRP sheet. When impacted by spalls or hails, they are hardly broken.

Corrosion resistance

The products resist various acids, alkalis and peroxides, especially suitable for application in the coastal areas and corrosive places.

Temperature performance

FRP Corrugated Lighting Sheet is a kind of hot solid high polymer materials. It is designed for normal use in temperatures from - 40℃ to120℃.

Temperature insulation

The coefficient of heat-conduction of FRP Corrugated Lighting Sheet is 0.18kcat / mhr℃ , only 1/4 of the glass. That is why it has a good property of temperature insulation.

Fire-retardant

Fire-retardant the fire-retardant of FRP Corrugated Lighting Sheet is divided into ordinary gradeⅠ and gradeⅡ. The oxygen index of the gradeⅠof fire retardant is ≥32, the grade retardant is ≥26. It meets the standards of the fire brigade department.

Heat stability

FRP Corrugated Lighting Sheet is a kind strengthening plastic of hot solid fiber-glass . Its coefficient of heat expansion is 2.2 x 10-5mm/mm/℃, only 2 times of metal materials. For this reason, when it matches with a metal sheet, the displacement is relatively small, not easy to leak.

- Q:What are the properties of the anti-corrosive synthetic resin tile, the roof of the family can use the anti-corrosive synthetic resin tile?

- Very suitable for acid rain-prone areas and coastal areas, the effect is particularly significant Home residential roof is able to use anti-corrosion synthetic resin tile, because the anti-corrosion synthetic resin tile also has the following advantages The front of the phone is followed by 0731 plus 2076 Kebao building materials to provide you with technical support We look forward to hearing from you Color lasting: Synthetic resin tile surface material is the choice of imported high weather resistance engineering made of resin In the natural environment with extraordinary durability, it even long-term exposure to ultraviolet light, moisture, heat, cold harsh conditions, can still maintain its color stability Sound insulation effect: Experiments show that: in the storm, wind and other external noise, synthetic resin tile has a good absorption of noise Impact resistance, low temperature performance: synthetic resin tile has a strong external capacity Experiments 1 kg steel ball from 3m high free fall will not produce cracks, low temperature impact resistance is also very significant Self-cleaning performance: synthetic resin tile surface is dense and smooth, with "lotus effect", itself is not easy to absorb dust, once the rain washed as clean, tile surface dirt was washed after the rain does not appear spotted color Installation fast: synthetic resin tile effective width of 800mm, pavement high efficiency; light weight, easy loading and unloading; installation accessories complete Green: synthetic resin tile does not contain asbestos and radioactive elements, and recyclable, in full compliance with green environmental requirements

- Q:What are the synthetic resin tiles for the roof? What is the benefit of using synthetic resin tiles

- Laying synthetic resin tile leveling layer after construction, to timely conservation, conservation time shall not be less than 14 days, and is strictly prohibited in the above ticking, weight, before installation with 2m by foot detection flatness, leveling layer surface flatness The allowable deviation is 5mm 2 Wooden roof wood surface is flat, the material deformation is small, the thickness of 12mm or more (according to the roof spacing selected plate thickness); wood and purlins or roof beams with galvanized nails or bolts and reliable connection 3 Steel roof roof steel structure requirements, purlin and other components to maintain the flat to ensure the flatness of the roof; node welding must comply with the construction specifications, to prevent illegal operations; all steel must be anti-corrosion treatment

- Q:What is the difference between synthetic resin tile and resin tile?

- Synthetic resin tile because of the use of different resin raw materials, so divided into at least two: . in the ASA ASA synthetic resin tile . fragile PMMA synthetic resin tile synthetic resin tile and resin tile is no different, are the same raw materials Into, just to describe the resin raw materials to distinguish, such as the building materials ASA synthetic resin tile on the 20-year warranty period, which is based on raw material quality and formula to protect the resin tile life.

- Q:Is it also used for heat preservation with synthetic resin tiles?

- weatherability: synthetic resin tile tile surface selection "SABIC" high weather resistance engineering resin, this resin in the natural environment with extraordinary durability, even if long-term exposure to ultraviolet and other harsh environments, can still maintain the color and Physical stability

- Q:150 square meters of housing roof pouring glazed tiles how much money

- Glazed tile is a small piece of a small piece of stitching, lap 1 square meters about 33 glazed tiles, glazed tiles of the market price of 2-2

- Q:Synthetic resin tile, is the type of building materials that are building materials? Where are they used?

- ) The use of high-tech chemical technology developed from the new building materials, with a light weight, high strength, high strength and strength of the new building materials, , Waterproof, moisture-proof, anti-corrosion, fire insulation, and other good features, generally applicable to the development zone Ping change slope, farmers market, shopping malls, residential quarters, new rural construction residents high-end villas, awnings, awnings, antique buildings The

- Q:Need anti-corrosion synthetic resin tile, who can provide anti-corrosion synthetic resin tile information to me, to be clear Oh

- 0mm anti-corrosion synthetic resin tile: according to the multiples of custom-made anti-corrosion synthetic resin tile color: jujube ? brick red ? gray ? blue ? green anti-corrosion synthetic resin tile: : 880mm; effective width: 800mm anti-corrosion synthetic resin tile total width: 1050mm; effective width: 960mm anti-corrosion synthetic resin Wavelength: 160mm; ? wave height; 30mm anti-corrosion synthetic resin tile pitch; 220mm anti-corrosion synthetic resin tile thickness 3

- Q:Resin composite materials and fiberglass compared to the seismic, mechanical strength, paint adhesion What are the advantages and disadvantages? Do not copy and paste

- For the viscous liquid or heated softening of the solid, usually heated when the melting or softening temperature range, under the action of external force can be plastic flow state, some properties and natural resin similar

- Q:My house is a resin tile, but the resin tile can only last three decades, three years later how to do it? It makes me depressed

- Resin tile is divided into natural resin tile and synthetic resin tile, the market called resin is generally synthetic resin tile

- Q:3.0 mm thickness of the synthetic resin tile weight is different? The price is not the same, the heavier the better or the lighter the better? Please explain why, thank you

- 2 to 14 (20 mm thickness) by weight of about 2

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass FRP Roofing Sheet of China Best

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords