Fiberglass FRP Phenolic Molded and Pultruded Grating

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

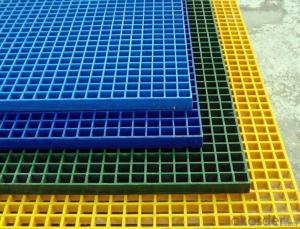

FRP Molded Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

Feature

Corrosion Resistance

Fire Resistance

Light Weight & High Strength

Safety & Anti-slip

Electrical Insulating

Aging Resistance

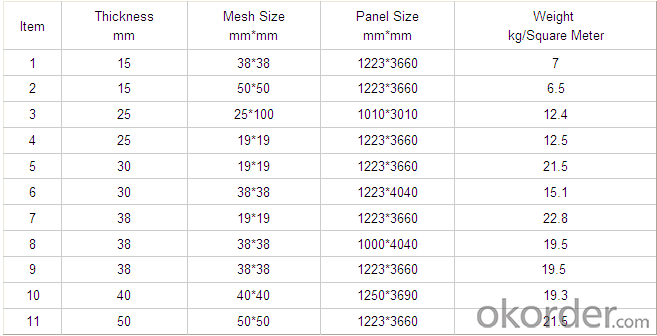

Specification

Advantage

coated with prevent aging layer

excellent insulating performance

no maintenance

high strength

long service life

easy installation

Application

Power plants, substation equipment enclosures, antimagnetic, anti-static,to prevent small animals into the equipment failure, as there is electricity facilities and without power interval intervals.

In high voltage electrical equipment for power line work, in order to prevent workers go wrong location, charged interval or near electrically charged equipment to dangerous distance.

Pool railings in sewage treatment industry

Corrosive chemical industry equipment around the fence

All kinds of building maintenance section

FAQ

1. How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List.Commercial Invoice, B/L, and other certificates as required by clients.

2. How long is the delivery time?

Usually it takes 10-25days after receipt of the deposits or L/C, and it also depends on the quantity of your order.

3. How's the payment?

Telegraphic Transfer(T/T) or Letter of Credit(L/C)

4. Do You Arrange Shipment?

Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you. For EXW price, clients need to arrange shipment by themselves or their agents.

5. How is the package?

Usually, we arrange the standard out-package for exporting.

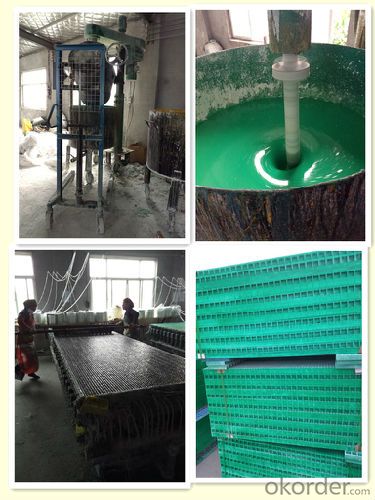

PROCESS

FACTORY

- Q:what is the fabric of the cloth? is it cotton?

- Im going to guess some kind of polyester cotton blend.

- Q:My future wife is looking to buy a weeding gown but she was curious to find out if satin is actually classified into different types or maybe the quality.

- wiggle it around a bit.

- Q:I have a section of cloth I would to fade, which I believe is a cotton/polyester blend. Sun fading has proven useless. Is there any other way to safely fade the cloth without making it form irregularities or patches?

- Soak the whole thing in bleach water.

- Q:Theoretically, can fiber glass cloth and carbon fiber cloth be used together to make a part? Is there a major structural disadvantage to this?

- Carbon fibre is the stronger weight for weight, and the most expensive.An important difference in some situations is that the carbon fibre is electrically conducting,not as a current carrier,it's not that good,but it could be useful where a build up of static charges is to be avoided.With respect to using the two materials together,they would probably delaminate quickly under stress because their elastic moduli are very different;also be aware that carbon fibre is graphite and it is difficult to protect the material from surface wear,graphite golf shafts are light and stiff but the necks soon loose there coating in the golf bag ;after that you could use the bare areas to write with.

- Q:Is the nylon material with glass fiber white?

- The addition of glass fiber to nylon does make a great difference in the colour and lustre of nylon

- Q:ok if i buy this hoodie thats say.100% cotton, how much would it shrink when i put it in the dryer? what about 80% Cotton and 20% Polyester.etc? like, would it shrink a few inches or what?

- If the tag on it says sanforized then it will shrink less than 1%

- Q:How can the toilet be waterproof?

- Ordinary residential toilet small place, and line wear floor etc., it is commonly used in waterproof coating and rarely used by waterproof membrane.There are 2 common waterproof coatings:Synthetic polymer - polyurethane waterproof coating (corner, polyester cloth, glass fiber cloth etc.)---S, B, S waterproof coating of polymer modified bitumen (reinforced matrix, polyester cloth, glass fiber cloth etc.)Asphalt based waterproof paint is basically no need.

- Q:How to separate the glass fiber FR-PPR and reinforce the composite tube?

- Normally, fiberglass tubing is good.

- Q:I want to use fleece bedding because it sounds much easier to clean up poops. I was wondering what you are supposed to put under the fleece to absorb the pee??? Please only answer if you have used fleece in a guinea pig cage!

- panasonic dmc-sz7 is the perfect camera for you and only 140 pound

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass FRP Phenolic Molded and Pultruded Grating

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords