Fiberglass Fabric Coated with Silicone Rubber

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Fabric Coated with Silicone Rubber

Fiberglass Fabric Description

Silicone coated fiberglass fabricare made of fine fiberglass with excellent capacity of high temperature and corrosion resistance, coated and rolled with silicone rubber, which is a brand new product with good performance and multiple applications.

Fiberglass Fabric Specification

Thickness:0.2mm-5mm

Width:100cm-150cm

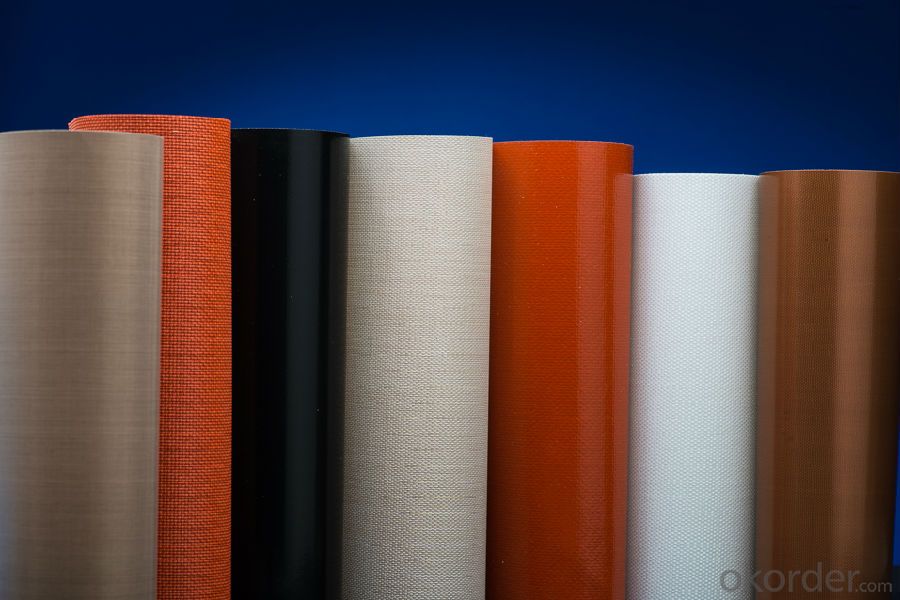

Color;grey/red/silver/black

Weight(coating):130gsm-2800gsm

Model No | FSD2030 | FSD2030 | FSD2050 | FSD2100 | |

High temperature resistant(°C) | ≤280 | ≤280 | ≤280 | ≤280 | |

Low temperature resistant(°C) | ≥-40 | ≥-40 | ≥-40 | ≥-40 | |

Tensile intensity (N/50mm) | Warp | ≥1750 | ≥1750 | ≥2500 | ≥3500 |

Weft | ≥1280 | ≥1280 | ≥2100 | ≥3000 | |

Inflating burst intensity(Mpa) | ≥2.0 | ≥2.0 | ≥2.2 | ≥2.6 | |

Peeling intensity(N/m) | ≥450 | ≥450 | ≥520 | ≥600 | |

Insulation (kv/mm) | 16 | 16 | 18 | 18 | |

Weight (g/m*m) | 550-650 | 550-650 | 750-800 | 1500-1800 | |

Width(mm) | 1000±20 | 1000±20 | 1000±20 | 1000±20 | |

Thickness(mm) | 0.3-0.4 | 0.3-0.4 | 0.05-0.55 | 1.0-1.1 | |

color | Silver-gray, gray, red | lucency | Silver-gray, gray, red | Black, gray, red | |

Fiberglass Fabric Features:

1, Good performance on resisting high temperature and low temperature, -40°C-280°C;

2, High strength;

3, Ozone, oxide, light and weather aging resistance;

4, High insulation: dielectric constant:3-3.2, breakdown voltage: 20-50KV/MM;

5, Chemical corrosion resistant, oil-proofing, waterproofing (washable)

Fiberglass Fabric Application:

1) Electric insulation: it feature high grade of electric insulation and bear a load of high voltage. It fits for making products like insulation cloth and sleeves et.

2) Non - metalli compensator: used as pipeline oupling, non-metallic compensactor helps to avoid damage caused by heat expansion and cold contraction. This membrane material speially fit for using in industres of petroleum, chemical engineering, cement, iron and steel and good elasticity and toughness.

3)Anti-conrrosion sector: It is good to be used as inner and outer anti-corrosion layer featuring excellent corrosion resistance, tempareture resistance and high strength. It proves to be an ideal anti-corrosion material.

4) Others: Apart from above application, it can also be used as sealing material, temperature resistant and anti-orrosion conveyr belt and packaging material.

Product Show

FAQ

1.What are the characteristics of fiberglass fabric?

a)Outstanding temperature resistance(from -70°C to +260°C)

b)Excellent chemical resistance

c)Superior non-stick surface, easy to clean

d)High dielectric strength

e)Dimensional stability

f)Resistance to UV, IR and HF

g)Non-toxic

2.How many methods to weave the fabric?

Four methods to weave the fabric:

a).Plain weave: it can be used in electricity insulation materials and reinforced materials in industry, because of inseparable structure, plain and clear lines.

b).Twill weave: compared with plain weave, it is of high density, high intensity, with a soft and loose structural weave. It can be used in ordinary reinforced materials, filter materials, and painting cloth.

3.Can you offer us some samples?

We are willing to offer our customers best product&service,if it's necessary we can send

you sample for test;also we welcome all you customer have a trial order.

- Q:Two, fat and PVC paste resin paste into the sizing, coated on glass fiber cloth, so that after baking, how do not shrink?

- The auxiliary plasticizer can be added, and the dissolving capacity of the auxiliary plasticizer is relatively small, and when used, the viscosity is reduced and the storage is favorable.

- Q:What is the typical tensile strength of fiberglass fabrics?

- The typical tensile strength of fiberglass fabrics can vary, but it is generally around 300-600 MPa (megapascals).

- Q:How does fiberglass fabric handle vibration?

- Fiberglass fabric is known for its excellent performance in handling vibration. Due to its unique composition and structure, fiberglass fabric has inherent properties that make it highly resistant to vibration. One key aspect that contributes to its vibration handling capability is its high tensile strength. Fiberglass fabric is made by weaving strands of fiberglass together, creating a strong and durable material. This high tensile strength enables the fabric to withstand the forces exerted by vibrations without undergoing deformation or damage. Additionally, fiberglass fabric has a low density, which means it is lightweight and has a high strength-to-weight ratio. This characteristic allows the fabric to effectively dissipate vibrations and absorb energy, minimizing the transmission of vibrations to the surrounding environment. Furthermore, fiberglass fabric is also known for its excellent dimensional stability. It maintains its shape and structure even under dynamic conditions, which is crucial in vibration-prone applications. This stability ensures that the fabric remains intact and functional, preventing any negative effects on the overall performance of the system. Overall, fiberglass fabric is a reliable and effective material for handling vibrations. Its high tensile strength, low density, and dimensional stability make it an ideal choice for various industries and applications where vibration control is essential.

- Q:Can fiberglass fabric be used for making shoes?

- Yes, fiberglass fabric can be used for making shoes. It is a versatile material that offers strength, durability, and resistance to wear and tear. It can be used in various shoe components such as the upper, reinforcement, or insoles to provide added support and stability. However, it is important to note that fiberglass fabric may not be as commonly used as other materials like leather or synthetic fabrics in the shoe manufacturing industry.

- Q:Can fiberglass fabric be used for making stage backdrops?

- Yes, fiberglass fabric can be used for making stage backdrops. Fiberglass fabric is known for its durability and strength, making it suitable for various applications, including stage backdrops. It offers excellent resistance to heat, fire, and chemicals, making it a safe and reliable choice for theatrical settings. Additionally, fiberglass fabric can be easily painted or printed on, allowing for customization and creative designs to enhance the visual appeal of the stage backdrop. Its lightweight nature also makes it easy to handle and install. However, it is important to note that fiberglass fabric should be properly treated with fire-resistant coatings or finishes to ensure safety in the event of a fire. Overall, fiberglass fabric is a versatile material that can be effectively used for creating stage backdrops.

- Q:How does fiberglass fabric perform in terms of moisture absorption?

- Fiberglass fabric is known for its excellent resistance to moisture absorption. Due to its non-porous and hydrophobic nature, fiberglass fabric does not readily absorb water or moisture. This property makes it highly suitable for applications where exposure to moisture or humidity is a concern. Additionally, the low moisture absorption of fiberglass fabric helps to maintain its structural integrity and dimensional stability, even in environments with high levels of moisture. Overall, fiberglass fabric performs exceptionally well in terms of moisture absorption, making it a reliable choice for various industries and applications.

- Q:Can fiberglass fabric be used for flags?

- Certainly! Flags can indeed be crafted using fiberglass fabric. Renowned for its durability, strength, and ability to withstand weathering, fiberglass fabric proves to be an ideal material for outdoor purposes such as flags. Despite its lightweight nature, it remains tear-resistant, enabling flags fashioned from fiberglass fabric to endure powerful winds and adverse weather conditions. Moreover, the fabric can be effortlessly printed on, granting the opportunity for vivid and enduring flag designs.

- Q:Is fiberglass fabric resistant to chemicals used in wastewater treatment?

- Fiberglass fabric exhibits remarkable resistance to the chemicals employed in wastewater treatment. Its outstanding chemical resistance has earned fiberglass a reputation as an optimal material for scenarios where exposure to diverse chemicals is probable. It has the capacity to endure a broad spectrum of corrosive substances, such as acids, alkalis, and solvents, commonly encountered in wastewater treatment processes. Due to the non-reactive quality of fiberglass fabric, it remains unaffected and undamaged when exposed to these chemicals, making it a dependable choice for implementation in wastewater treatment facilities. Additionally, fiberglass fabric also offers resistance to UV radiation, moisture, and fluctuations in temperature, which further bolsters its durability and suitability for such environments.

- Q:Can fiberglass fabric be used for reinforcement in sporting equipment?

- Yes, fiberglass fabric can be used for reinforcement in sporting equipment. Fiberglass fabric is known for its high strength-to-weight ratio and excellent durability, making it suitable for various applications, including sporting equipment. It can be used to reinforce the structure of items such as skis, surfboards, tennis rackets, bicycles, and hockey sticks, among others. The fiberglass fabric is often layered or laminated with other materials to create a composite structure that provides added strength and stiffness while remaining lightweight. This reinforcement enhances the performance and longevity of the sporting equipment, making it a popular choice among manufacturers.

- Q:Is fiberglass fabric resistant to fire in public buildings?

- Yes, fiberglass fabric is highly resistant to fire, making it a suitable choice for public buildings where fire safety is a concern.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass Fabric Coated with Silicone Rubber

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords