Fiberglass Chopped Strand Mat for Sales Fiberglass Mat

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Chopped Strand Mat for Sales Fiberglass Mat

Introduction:

Fiberglass chopped strand mat is a non-woven E-or C-glassfiber mat, product manufactured by spreading continuous filament roving of 50mm in length randomly and uniformly in combination with polyester binder in powder form (or other binder in emulsion from). This product is characterized by good combination of resin, easy operation, good wet strength retention, good laminate transparency and low cost. It is suitable for the applications of hand lay-up FRP moldings, such as various sheets and panels, boat hulls, bath tubs, cooling towers, corrosion resistant, vehicles etc.

Function:

Fiberglass chopped strand mat is chopped using the "E" chopped glass and emulsion adhesive bond. It is suitable for hand lay and can enhance the unsaturaed ployester resins.

Product Features:

Consistent thickness and stiffness;

Rapid impregnating and good compatibility with resin;

Superior wet through with less air trap;

Good mechanical properties and high strength of parts.

Superior acid corrosion resistance

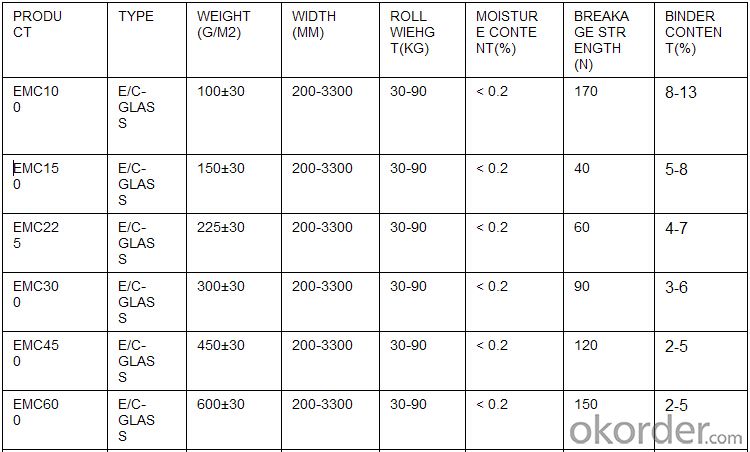

Technical Data:

FAQ:

Is sample available ?

Yes, we provide the free samples, but customers themselves need pay the shipping fee

What's your MOQ?

Our MOQ is one 1*20' full container loading

How do you pack the fiberglass

(1) First, the mat is in roll packed in White PE fIlm.

(2) Then the rolls packed in the carton

4.Which knid of payment terms can you accept?

We can accept 30% prepayment, 70% payment before shippment. LC is also accepted

- Q:Are there any specific certifications or standards that fiberglass mat tissue must meet?

- Certifications and standards are necessary to guarantee the quality and appropriateness of fiberglass mat tissue for different purposes. The ASTM D 4601 standard is widely recognized and specifies the minimum requirements for glass fiber mats used in roofing and waterproofing systems. It covers various physical properties like weight, thickness, tensile strength, tear resistance, and water resistance. Apart from ASTM D 4601, fiberglass mat tissue may undergo testing based on its intended usage. For example, if it is used in the automotive industry, it may need to meet ISO 9001 or IATF 16949 standards, ensuring quality management systems and product consistency. Furthermore, fiberglass mat tissue used in construction or building materials should adhere to regulations set by organizations like the International Code Council (ICC), the American National Standards Institute (ANSI), or the Underwriters Laboratories (UL). These standards primarily focus on fire resistance, thermal insulation properties, and overall safety. Ultimately, the specific certifications and standards that fiberglass mat tissue must meet depend on its intended application and the industry it is used in. These standards are pivotal in ensuring the quality, performance, and safety of fiberglass mat tissue products.

- Q:What is the shelf life of fiberglass mat tissue?

- The duration for which fiberglass mat tissue remains usable can differ based on various factors, including how it is stored, its packaging, and the recommendations of the specific manufacturer. In general, if stored in a cool and dry location without being opened, fiberglass mat tissue can maintain its quality for approximately one to two years. However, it is crucial to be aware that the material may deteriorate or lose its physical characteristics over time, which can impact its effectiveness and suitability for use. Consequently, it is recommended to consistently refer to the manufacturer's instructions or directly consult with them for the most precise information concerning the shelf life of a particular fiberglass mat tissue product.

- Q:Can fiberglass mat tissue be used for repairing fiberglass truck beds?

- Yes, fiberglass mat tissue can be used for repairing fiberglass truck beds. It is commonly used in such repairs due to its strength, durability, and ability to bond well with the existing fiberglass surface.

- Q:What are the different manufacturing processes for fiberglass mat tissue?

- Various manufacturing processes exist for fiberglass mat tissue, each aiming to create a distinct mat type with unique characteristics. One prevalent method is the wet-laid process. Initially, glass fibers are chopped into small fragments and dispersed in a water-based slurry. This slurry is then spread onto a moving screen or belt, allowing the water to drain off and generating a mat composed of randomly oriented fibers. Subsequently, the mat is dried and further treated to achieve the desired thickness and density. Another technique is the dry-laid process. Here, glass fibers are first transformed into a loose, fluffy mat using either air or mechanical means. Subsequently, the loose fibers are bound together using a binder material, such as resin or latex, which is sprayed onto the fibers. The binder solidifies, resulting in a cohesive mat with controlled thickness and density. A third process is the stitch-bonded process. In this procedure, individual glass fibers are mechanically stitched together using a series of needles. These needles pierce the fibers and interlock them, producing a bonded fabric. This approach enables the production of mats with high strength and dimensional stability. Lastly, the spunbond process involves extruding molten glass through fine spinnerets to create continuous filaments. These filaments are then accumulated onto a moving belt or screen, where they are bonded together using either heat or a binder. This method generates mats with uniform fiber distribution and high strength. In summary, the selection of a manufacturing process for fiberglass mat tissue depends on the desired properties of the final product, including strength, thickness, density, and dimensional stability. Each process possesses its own advantages and disadvantages, and manufacturers will choose the most suitable method based on their specific requirements.

- Q:Can fiberglass mat tissue be used for automotive applications?

- Yes, fiberglass mat tissue can be used for automotive applications. Fiberglass mat tissue is a versatile material that is commonly used in the automotive industry for various purposes. It is often used as a reinforcement material in composite parts, such as bumpers, body panels, and interior components. The high strength and lightweight properties of fiberglass mat tissue make it an ideal choice for automotive applications, as it helps to enhance the overall performance and durability of the vehicle. Additionally, fiberglass mat tissue can also provide excellent sound insulation and vibration damping properties, which are crucial for improving the comfort and noise reduction in automobiles. Overall, fiberglass mat tissue is a reliable and widely used material in the automotive industry, contributing to the production of high-quality and efficient vehicles.

- Q:Is fiberglass mat tissue compatible with different resin systems?

- Yes, fiberglass mat tissue is compatible with different resin systems. It can be used with various types of resins such as polyester, epoxy, vinyl ester, and even thermoplastics. The fiberglass mat tissue acts as a reinforcement material that enhances the strength and durability of the final composite product when combined with different resin systems.

- Q:What is the chemical resistance of fiberglass mat tissue?

- The excellent chemical resistance of fiberglass mat tissue stems from the inherent properties of the fiberglass material. Typically, the mat tissue consists of woven or bound glass fibers, forming a protective barrier against a diverse array of chemicals. The glass fibers themselves possess a high resistance to corrosion, rendering fiberglass mat tissue suitable for use in environments where chemical exposure is a concern. The chemical resistance of fiberglass mat tissue can vary based on the specific resin or binder used in the manufacturing process. Various types of resins may offer superior resistance to certain chemicals, while others may be more susceptible to degradation. It is crucial to consider the specific chemicals that will come into contact with the fiberglass mat tissue and choose a compatible resin or binder accordingly. In general, fiberglass mat tissue is renowned for its ability to withstand acids, alkalis, solvents, and other commonly found industrial and commercial chemicals. It can endure exposure to a wide range of corrosive substances, making it a versatile and long-lasting material for various applications. Nevertheless, it is important to note that prolonged exposure to highly concentrated or aggressive chemicals may eventually result in some degradation or deterioration of the fiberglass mat tissue. Therefore, it is imperative to consult the manufacturer's specifications and guidelines to ensure proper chemical compatibility and performance in specific environments.

- Q:What is the thermal resistance of fiberglass mat tissue?

- The thermal resistance of fiberglass mat tissue depends on various factors such as the thickness of the mat, the density of the fibers, and the presence of any additional materials or coatings. Generally, fiberglass has a low thermal resistance, meaning it is a good conductor of heat. However, when used as insulation, the thickness and density of the fiberglass mat can increase its thermal resistance, making it more effective at reducing heat transfer. It is important to note that specific values for thermal resistance can vary depending on the specific product and application, so it is recommended to consult the manufacturer's specifications for accurate information.

- Q:Can fiberglass mat tissue be used for flooring insulation?

- Typically, fiberglass mat tissue is not employed for flooring insulation. It is a lightweight substance frequently utilized in the construction sector to reinforce plaster and concrete, and as insulation in walls and ceilings. However, for flooring insulation purposes, other materials like foam boards or batt insulation are generally favored. These materials offer superior thermal and sound insulation features that are specifically tailored for flooring applications. Moreover, they are simpler to install and better equipped to endure the pressures and demands of foot traffic on the flooring.

- Q:Is fiberglass mat tissue resistant to mildew and rot?

- Yes, fiberglass mat tissue is resistant to mildew and rot.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass Chopped Strand Mat for Sales Fiberglass Mat

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords