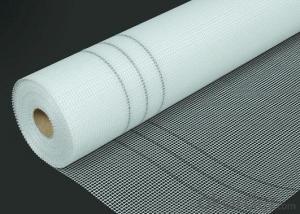

Fiber Glass is Woven by Glass Fibers/Plain Woven/mainly used as banding tapes for insulation

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 500 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Henan, China (Mainland) | Brand Name: | cnbm | Model Number: | FG60-300g/m2 |

| Application: | Wall Materials | Weight: | 60,75,90,110,125,145,160g | Width: | 1m,16.6cm |

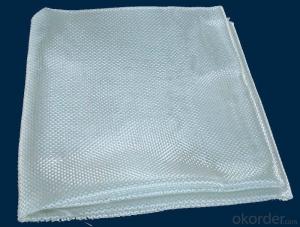

| Mesh Size: | 4x4,5x5,10x10mm | Weave Type: | Plain Woven | Yarn Type: | E-Glass |

| Alkali Content: | Medium | Standing Temperature: | 300 | item: | Fiberglass mesh |

| Certificate: | ISO9001:2000 | Europe Certificate: | ETAG | Glue coating: | Acrylic acid 16-18% |

| Weave type: | Leno | high strength mesh: | fireproof mesh | soft mesh: | hard and medium hard mesh |

Packaging & Delivery

| Packaging Details: | packed in shrink film then packed in carton with pallet or without pallet.30 rolls/carton or 6 rolls/carton. 75g/m2, 170000m2/40'HC. 145g/m2, 110000m2/40'HC.160g/m2, 110000/40'HC. |

| Delivery Detail: | delivery 1X20GP' in abt 8 days after order |

Specifications

1)Supply CE,ITB,ISO9001

2)Help customer avoiding anti-dumping duty

3)Platinum glass fiber roving

4)Acrylic glue content 16-20

Fiberglass mesh is woven by platinum fiberglass yarn and then treated with acrylic glue. It has fine alkaline-resistant, high strength, etc. As an ideal engineering material in construction, fiberglass mesh is mainly used to reinforce cement, stone, wall materials, roofing, bitumen, gypsum, waterpoof and so on.

Fiberglass mesh high quality ability:

1) warp and weft of mesh is very straight, also bright surface.

2) Coating enough alkaline resistant glue and keep 60% - 80% strength after testing in Naoh 28 days later

3) Made by C-glass fibers woven roving as basis material, and then treated with acrylic acid copolymer liquid, glue content:14-18%

4) High tensile strength, the mesh is not easy be teared.

5) Small sample free

Main specs:

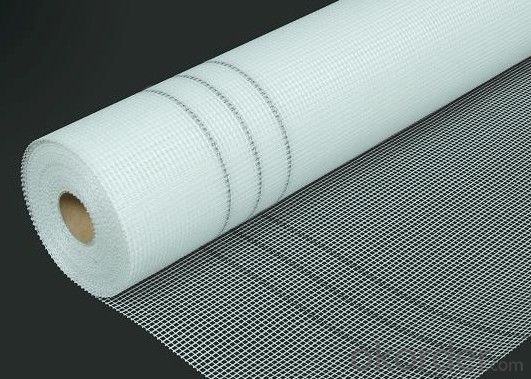

5mm x 5mm/75g/m2, 90g/m2, 125g/m2, 145g/m2, 160g/m2,etc.

4mm x 4mm/75g/m2, 90g/m2, 110g/m2,125g/m2, 135g/m2, 145g/m2, 160g/m2, etc.

10mm x 10mm/90g/m2, 110g/m2, 125g/m2, 135g/m2. 145g/m2, 150g/m2,160g/m2,etc.

2.85mm x 2.85mm/60g/m2, 75g/m2,etc

plain weave : 10X20mesh/inch:60g/ m2,etc

Packing

Inner packing: shrinkage packing one roll ,then 30 to 52 rolls/pallet or 4 rolls/carton

We get ISO9001:2000, ITB and Europe ETAG certificate.

- Q:whether the sound insulation is asbestos good or the glass wool good?

- Because the main function is the fireproofing), sound absorption cotton belongs to asbestos, but match up with the installation (glass fiber cloth, and we in real life (in fact, we need the material with good sound insulation

- Q:Is the glass wool sound insulating? How good is it?

- Is it used on car?

- Q:Which kind of thermal insulation glass wool is the best?

- Glass wool is a good choice. Glass wool can be said centrifugal, so it is also known as centrifugal glass wool, whose thickness and volume-weight have somewhat effect on its sound absorption property. Meanwhile, its sound absorption property is also affected by the cover material and the structure construction. It is necessary to use centrifugal glass wool properly based on its various characteristics like its appearance, fire-resistant capability and anti-aging ability in application to specific buildings. In addition, centrifugal glass wool can be cut freely and it has a stable physical properties. Glass wool is a product made by adopting peculiar centrifugation technology, the technology that fibering molten glass and then processing the added thermosetting resin-based adhesives with environment-friendly formula to manufacture the final products. It is a felty body with elasticity made by stacking of glass fiber whose diameter keeps merely several micrometers. Centrifugal glass wool's detailed technical characteristics include thermal insualtion, excellent shock absorption and sound absorption, and noise absprption capabilities for low and medium frequency noise and vibration noise in particular. It helps a lot in reducing noise pollution and improving the working environment. Glass wool with aluminum foil veneer has a strong thermal radiation resistance as well, which makes it a superb lining material applied in high temperature workshops, control rooms, inner wall of machine rooms, compartments and flattops.

- Q:The difference between glass wool of 50mm and rock wool.

- Glass wool belongs to one of the glass fiber. machine-made fiber cotton wool molten glass fibrosis cotton material belong to glass fiber. type, bulk density, low thermal conductivity, thermal insualtion, acoustic insualtion, anticorrosion, stable chemical performance. Rockwool is also called mineral wool. Use Guangde Shida rock wool and mineral raw materials to make fluffy short fine fibers. Basalt rock wool, pyroxenite, dolomite, iron ore, bauxite can be used to make matrix fiber by going through high temperature melting process and fibrosis.

- Q:What are the raw materials of centrifugal glass wool?

- Although I see it every day, but I really do not know about it, I only know that the main materials include glass and lime.

- Q:What kind of glass wool pipe is this? Where is it sold?

- It seems to be made in a small plant.

- Q:What is the difference between quartz wool and glass wool?

- Quartz wool / glass wool / insulated cotton [Instrument]. Products introduction: quartz wool: it is used as the filler of analytical instruments or small reaction tubes in laboratory, or as the insulation material. Temperature resistance: about 1300 degrees. Specifications: 1 to 3um and 3 to 5um. Packaging:

- Q:What is semi-rigid glass wool board

- Glass wool is a glass wool felt made by melting the glass after being melted by adding a binder, and the diameter of the glass wool fiber depends on the centrifugal extrusion technique

- Q:These two kinds of glass wool are used as insulation materials, but one keeps 0.3 in specific gravity while the other keeps 0.5 in specific gravity. Which one should be chosen?

- It mainly depends on what would you use it for and what temperature of thermal insulation do you need. You can directly look through thermal insulation property of glass wool for further information. If you needs better thermal insulation effect, you can choose heavier specific gravity. If you are not so demanding, you can choose lighter ones.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiber Glass is Woven by Glass Fibers/Plain Woven/mainly used as banding tapes for insulation

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 500 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products