Fiber Cement Board High Quality Reinforced

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 450 pc

- Supply Capability:

- 4500 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiber cement board is non-asbestos fiber cement product opposed of Portland cement, cellulose fiber and refined sand. Using a special

manufacturing process called autoclave; fiber cement board acquires the strength, durability of cement and easy workability of wood as well as dimensional stability. A non-combustible multi-purpose application fiber cement flat board, fiber cement board comes with various thicknesses which are suitable for various applications: ceiling, wall and floor. It can be used for both exterior and interior applications. Fiber cement board can perfectly be calibrated and then laminated or coated with other materials, such as wood veneer, painting, and steel cover.

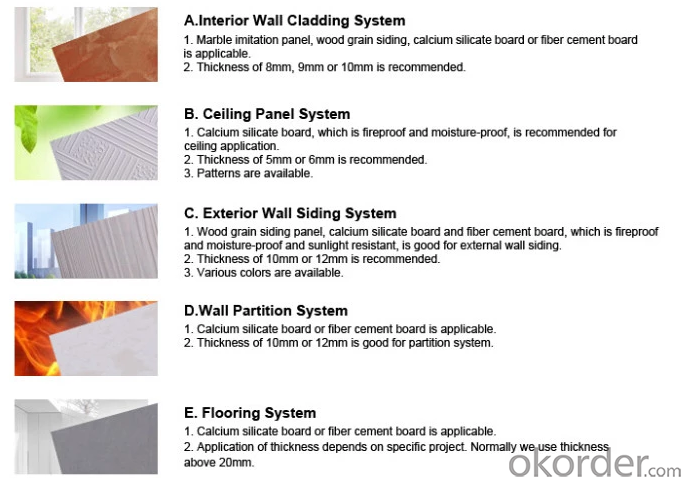

Where can be Fiber Cement Board used for?

Fiber Cement Board is the perfect Choice for building board application such as wall cladding, wall partition and decorative wall. The types of buildings that are suitable for fiber cement board applications are residential, commercial and industrial buildings as well as schools and hospitals, especially where speedy construction, cleanliness and hygiene is of high importance.

Specifications:

1) Dimensions: 1220mm*2440mm

2) Thickness: 4 -30mm

3) Other specifications available

4) Density: 1.1-1.5g/cm3

5) We supply the board with bevel edge in two edges or four edges and square edge

6) Physical properties

A) Bending strength: E 9MPa (in vertical), e7MPa (in paralle)

B) Moisture movement: D0.2%

C) Water content: 10%

D) Thermal conductivity: D0.29W/m. K

E) Continuous anti-freezing: -30oC

F) Anti-high temperature: +120oC

7) Combustibility: Up to the standard of GB 8624, In-combustibility Class A, also up to the standard of BS 476 part 4: 1970, part 6: 1979 and part 7: 1997

Product characteristics:

1) Non toxic

2) Fireproof

3) Soundproof

4) Sawable

5) Thermal insulation

6) Impact resistant

7) Planeable

8)Mothproof

9) Moisture proof

- Q:can cement board be cut into narrow 6 strips and used to make wall studs?

- No, it provides nothing to nail into, which is the purpose of studs and it has very limited strength if in a load bearing wall. And if you mean cutting a whole bunch of pieces and stacking them to get a 6 wide by 3.5 deep (like a 2x4) it would be a huge waste of materials and cutting blades. If you are looking for fireproof, consider metal studs. If you are looking for sound proofing, use offset stud techniques.

- Q:I'm preparing to replace the tiles in my foyer. It's a townhouse, about 20 years old with no basement. I don't know much in the way of construction, but since it's on ground level I think there might just be a cement slab underneath the existing tile. Can I install the tiles directly over the cement slab after removing the old tile or do I need a backer board? And if I do, how do I account for the height difference? Thanks in advance!

- Cement board is only 1/2 thick, concrete would be at least 2 ( probably 6 thick) you will know the difference by taping it with a hammer. You can remove the existing tiles and install new tiles onto the existing concrete. If any concrete is broken or damage, you will have to patch the broken concrete, let dry, and install tiles 24 hours later. Wait 24 hours before you grout.

- Q:How to remove the paint on the surface of the cement board

- Cement ladder on the paint, if it is to be in the above pavement marble, do not have to remove the paint. It is very strenuous thing. But with a chisel to ladder out some of the nest, that is, on the line on the line. This can be improved with marble and stickiness.

- Q:installed the most powerful exhaust fan that is made and my newly painted hardi backer walls are sweating when take a shower or bath with the fan running- what can I do?

- is it the outside wall.it may need to be insulated.

- Q:Aluminum-plastic board Aite board lighting board are used in what place

- Aluminum plate and the purpose of the board should be roughly the same, such as the inner wall and the wall and cut off! The But the Etter board is the fiber cement board can do LOFT mezzanine.

- Q:Wood fiber cement board | US rock cement board use

- Wood fiber cement board for a new generation of high-quality and economical new building materials, the special surface lines can show high value texture and unique taste. More valuable is that wood cement or high-quality multi-purpose building materials.

- Q:Can cutting the steel cutting machine cut the cement board?

- Cutting the steel cutting machine can not cut the cement board. Cut the reinforced toothless saws are grinding wheel pieces, and cutting the concrete slab to use the toothless alloy steel saw blade.

- Q:This building was previously a school building, with cement block walls..I need to know if I need backer board, or do I just need to fill in the low spots to make the wall flat and level? Also, what kind of thinset do I need for clear glass mosaics?

- You don t need a backer board.. As long as the block is solid and no cracks ( they need to be treated specially) you can go right over the block with a few precautions. The block needs to be clean and smooth. No mortar from the joints and stick out. If the walls are unpainted ( and clean) you can go over them with WHITE and white only thin set.There is no such thing as colored or tinted thin set.And glass tiles call for a strong latex modified thin set If the walls are painted ( and clean) you can use a mastic or the special thin set. Fill in the mortar joints with the adhesive you use. Mastic cannot be used if this is a wet area or going to be a wet area. Any questions you can e mail me through my avatar and check my qualifications there. GL

- Q:my fiberglass shower pan was cracked and my tiles were coming off. so I took out the tiles and greenboard, and replaced the shower pan. unfortunately, they do not carry the same size of shower pan - I am short about 1/4 inch on all sides. what do I do in order to line up the cement board with the existing drywall? i only plan to replace the area where the old tiles were. i am afraid I have to tear down all the drywall but I really don't want to. thanks.

- Pull the pan out and put a sheet of 1/4 inch cement board under it then reinstall the pan....

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiber Cement Board High Quality Reinforced

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 450 pc

- Supply Capability:

- 4500 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords