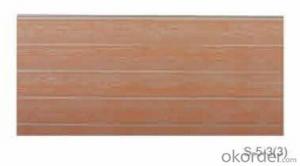

Fiber Cement board for villas,high building-014

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The fiber cement board includes two series: solid fiber cement board(S series) and hollow fiber cement board (K series)

Fiber cement board is one new type wall board which is both functional and decorative, with idea of high- tech and innovation, the products combine the traditional and modern science and technology, which provide a brand new green wall decoration material to the exterior wall field.

K series

3000 * 300* 15mm

3000* 450* 18mm

3000*600* 26mm

K series—Streak board

3000*300*18mm

3000*300*22mm

3000*600*26mm

The colors are based on customer’s choice.

Fiber cement board: exterior wall decoration system

This system is widely used in public building and high end residential and other kinds of civil construction of exterior wall decoration. In existing buildings exterior wall decoration, the fiber cement board can be directly mounted to the exterior wall by keel, and not need to remove the original façade decoration materials. This system could give the construction quick speed, low transformation cost and good decorative effect.

Fiber cement board: exterior wall heat preservation system.

This system can meet different design requirements for energy- saving. The system has excellent heat preservation and heat insulation performance, meanwhile, the mass production and quality control of the products overcomes the crack problem occurred in other external insulation system. The system are mainly used in energy saving renovation to existing building or the external wall thermal insulation of new construction.

Fiber cement board composite wall system has good heat preservation, heat insulation and sound insulation performance, which make the system become an high and energy saving wall retaining system. The system could be applicable to the façade of steel or wood frame villa, and non bearing exterior wall for structural frame work or other frame structure.

- Q:I would like to build 4 steps on a incline. It is above a retaining wall but will be a good foot away from the wall all on firm packed dirt. I have a couple questions. One side of the steps would be next to the garage wall.1. Can I pour cement up against the cinder wall?2. If so how would someone build steps form without any boards against the one side. So basically just have the one side and front plate.3. Or would you recommend having a board against the wall. Or pull it out after the form has set?

- have you thought of buying a precast fiberglass step, they go well with weather, they are strong and you can pain them if you like. Home Depot might have some

- Q:Hi everybody! I just installed hardibacker boards in my bathroom. But I had to remove 1 pc 'coz I made a mistake. Can I still use it again? I screwed it every 8 inches around the edges and along every stud. Can I just cover the holes with thinset? Thanks!

- Yes, as long as you adequately fill the holes, you're good to go

- Q:What are the standards for residential steel structures?

- China's steel structure housing industry has entered a new stage of development, the standard standards and architectural standards have been released to implement the design, coupled with adequate supply of domestic steel, but also a number of steel structure pilot project and demonstration project construction experience and scientific and technological achievements, The development of steel structure has a better material and technical basis. Of course, the promotion and improvement of different types of structural design specifications and construction technology standards, the development of new lightweight insulation wall materials and supporting the issue of residential parts, need to do a lot of work. At the same time, but also widely publicized the advantages of the development of steel housing, so that more developers, designers and users understand the understanding of steel housing.

- Q:Lightweight composite wallboard can not be attached to the wall

- Light composite wall panels, is for modern high-rise buildings, ecological residential interior space, size and structure, and the development and production of solid light wall panels, due to its unique performance characteristics, the market also known as "light composite wall panels "," Light wall panels "," solid wall panels "," composite wall panels "," strip wall panels "and other names, hereinafter referred to as lightweight composite wall panels.

- Q:what does this mean second phase in two phases material ( first phase is binding cement ) ?

- First consider the term 'phase' as in 'phase change', such as ice melting. It means a particular state of matter, solid or liquid in the melting of ice. However, in an inhomogenous solid material you can have two or more solid phases. For instance, Transite insulation board was made of portland cement and asbestos [not in use much nowadays]. So what you have is some two phase inhomogenous solid consisting of one phase as binder or cement, and the other phase could be a filler, a fiber, or whatever.

- Q:I've done the hard way - bunches of expensive special screws. I found that to be expensive and time consuming (and therefore back breaking). It seems like it takes just as long to do the backer board as it does to do all the remaining steps with the tile. Can I use nails? If so, what kind? Thinset and nails? The subfloor is plywood with old vinyl tiles, I have no intention of remove the old vinyl tiles first. Please reply if you have personal experience with an alternative. Thanks!

- If you want it to last you should thin set AND screw the cement board down. Cement board is not just used in wet areas. It is a dimensionally stable product and properly installed it will keep your tile and grout from cracking and/or coming loose. If you try to scimp on the prep then you will be wasting your time and money. Some installers do nail it down but bare in mind that this will void any warranty. Don't forget to tape the joints too. If the vinyl tiles are down tight and height room to room is not an issue then leave it in place and go over top.

- Q:Wood keel cement pressure plate partition wall tiles

- Before the tiles, the cement board should first use the interface agent to brush, then paint a layer of 1 cm or so of cement mortar, the label is appropriate high; 24 hours after the water to do maintenance (to prevent the paint layer too dry), 48 hours After the tile can be posted (at this time the strength of the paint layer has not yet reached, when the tile can not be applied to hit the force); tiles must be fully soaked.

- Q:I am in the Chicago area and it rained a few days ago.... I am also using molds and wood 4x4's

- you lost me at molds. If you poured your holes monday, they should be ready to pound on by saturday, that's conservative given the rain and all.

- Q:Can cement board be tiled?

- Kitchen flue is made of cement board if the wall is not hard to use the red brick and then posted again

- Q:Thanks Alex. How much you think I should charge to install each 4x8 sheet of cement board?

- I used to charge 2.50$ a s/f to install board or prep an area. That would include the board , thin set and nails ( or screws)to do it properly. 4x8 cement board is hard to find and heavier the all HE!!, so hire a friend. 3x5 sheets are much easier to handle by yourself. Any questions you can e mail me through my avatar. GL

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiber Cement board for villas,high building-014

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords