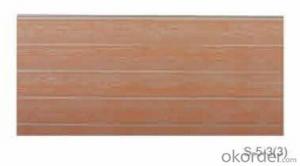

Fiber Cement board for villas,high building-013

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The fiber cement board includes two series: solid fiber cement board(S series) and hollow fiber cement board (K series)

Fiber cement board is one new type wall board which is both functional and decorative, with idea of high- tech and innovation, the products combine the traditional and modern science and technology, which provide a brand new green wall decoration material to the exterior wall field.

K series

3000 * 300* 15mm

3000* 450* 18mm

3000*600* 26mm

K series—Streak board

3000*300*18mm

3000*300*22mm

3000*600*26mm

The colors are based on customer’s choice.

Fiber cement board: exterior wall decoration system

This system is widely used in public building and high end residential and other kinds of civil construction of exterior wall decoration. In existing buildings exterior wall decoration, the fiber cement board can be directly mounted to the exterior wall by keel, and not need to remove the original façade decoration materials. This system could give the construction quick speed, low transformation cost and good decorative effect.

Fiber cement board: exterior wall heat preservation system.

This system can meet different design requirements for energy- saving. The system has excellent heat preservation and heat insulation performance, meanwhile, the mass production and quality control of the products overcomes the crack problem occurred in other external insulation system. The system are mainly used in energy saving renovation to existing building or the external wall thermal insulation of new construction.

Fiber cement board composite wall system has good heat preservation, heat insulation and sound insulation performance, which make the system become an high and energy saving wall retaining system. The system could be applicable to the façade of steel or wood frame villa, and non bearing exterior wall for structural frame work or other frame structure.

- Q:Asbestos cement board product features

- Waterproof and moisture: in semi-open air and high humidity environment, can still maintain the performance of stability, not subsidence or deformation.

- Q:What is the process of using a cement pressure plate to dry the tile? What do I need to know about the specifications of the light steel keel, how thick the board

- Process: the traditional, inconvenient practice is to use the steel wire hanging and then wiping the cement leveling, and then use the wet paste tiles. My advice is to use tile adhesive paste directly tile, fast efficiency, and after the process of ditch groove beautiful, unlike the cement paste the black seam.

- Q:How about wood wire cement board? Is it environmentally friendly building materials?

- In the production and processing process, wood in the wood board of wood components through non-toxic chemical mineralization after the fire produced. These treated mineralized wood components combine with the Portland cement base to increase its strength and toughness, resulting in significant structural features and excellent quality of Portland cement: fire, moisture, Corrosion, pest control, and durability. The overall structure of the wood fiber board makes it resistant to impact and easy to process. Due to the close structure, high density, wood fiber reinforced concrete board sound insulation is excellent, and affordable,

- Q:our cement board was left out in a rain storm and then was installed under marble tiles. will this be an issue?

- Yes it can, but makes sure its dry before it gets closed off (tiled over)

- Q:Hello, my husband and myself are remodeling our bathroom....here's the question... we removed hideous vinyle tiles and underneath is the cement floor with thin layer of black adhesive from the tiles....the floor is pretty sound except for a small crack in cement by the entry door.... should we fix the crack and tile over the cement? or thin set 1/4''cement fiber board to the floor and tile over that? and if we do use the fiber board is the thin set enough to hold it down? we can't really screw/nail it cuz subfloor is cement. Any help is appreciated! Thanks!

- Always use backer board! Expansion and contraction will crack every grout joint if you dont use it. The only exception is if you use a rubber based emulsion on the floor first and add fiberglass mesh. I dont know of one county in the United States that has building code other than what I stated. Look up the United States UBC (Uniform Building Code). Dont take my word for it... Contact your local building inspectors office and ask. They are there to protect the consumer and residents against guys like the one that posted before me (with all due respect).

- Q:Meiyan cement board manufacturers of high quality products do

- The main purpose of the US rock plate is to use its close to the color of the cement front, so that the effect of the concrete is decorated with the concrete;

- Q:Can you use rubber cement on a science fair poster board to glue papers down?

- Rubber cement will damage some plastics and polished surfaces. If that is not a problem, then it can form a strong yet flexible bond, so may be suitable for your purpose.

- Q:some say lay 15 pound paper what gives?

- It's a cushion -bed for the cement board. Less chance of it cracking if cushioned.

- Q:What is the average price for hardieplank(cement board) installation?

- Anywhere from $10 to $15 per square foot depending upon how cut up it is. Large walls with not many cuts - $10. Small expanses with lots of angles and cutting - $15 of more if really complex. This includes the hardie product, the water proofing and the fasteners.

- Q:Can i tile over plywood floor, without using cement board?

- No.... just plywood sub floor doesnt allow the proper support for ceramic. Total thickness must be a minimum or 1 1/4 substrate to allow for tile. This is why cement board (1/2) makes an ideal substrate for tile. There is a way to do an extra layer of wood (1/2) but this is a very specific process and must be done right to work.. Now if your doing a vinyl tile you can use a vinyl tile directly over a wood sub floor although a new thin wood (1/4) is suggested to allow the glue to adhere to new wood better. Any questions you can e mail me through my avatar and check my qualifications there. GL

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiber Cement board for villas,high building-013

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords