Fiber Cement board for villas,high building-004

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The fiber cement board includes two series: solid fiber cement board(S series) and hollow fiber cement board (K series)

Fiber cement board is one new type wall board which is both functional and decorative, with idea of high- tech and innovation, the products combine the traditional and modern science and technology, which provide a brand new green wall decoration material to the exterior wall field.

K series

3000 * 300* 15mm

3000* 450* 18mm

3000*600* 26mm

K series—Streak board

3000*300*18mm

3000*300*22mm

3000*600*26mm

The colors are based on customer’s choice.

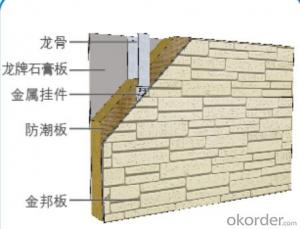

Fiber cement board: exterior wall decoration system

This system is widely used in public building and high end residential and other kinds of civil construction of exterior wall decoration. In existing buildings exterior wall decoration, the fiber cement board can be directly mounted to the exterior wall by keel, and not need to remove the original façade decoration materials. This system could give the construction quick speed, low transformation cost and good decorative effect.

Fiber cement board: exterior wall heat preservation system.

This system can meet different design requirements for energy- saving. The system has excellent heat preservation and heat insulation performance, meanwhile, the mass production and quality control of the products overcomes the crack problem occurred in other external insulation system. The system are mainly used in energy saving renovation to existing building or the external wall thermal insulation of new construction.

Fiber cement board composite wall system has good heat preservation, heat insulation and sound insulation performance, which make the system become an high and energy saving wall retaining system. The system could be applicable to the façade of steel or wood frame villa, and non bearing exterior wall for structural frame work or other frame structure.

- Q:I'm getting my bathroom shower tile installed and was told to get 4 sheets 1/2 thick backerboard with screws and I need to know if there is a difference between Cement Board and Backer Board?

- Cement board and backer board are the same things and for use in the shower I recommend and use 1/2 cement board. Cement board comes in 3'x5' sheets so make sure you have enough as blue board,another type of backer board comes 4'x8'. Good luck with your project.

- Q:Older house, kitchen floor. There's 3/4 diagonal wood on floor joists after hardwood floor is removed. Can I put down 1/2 plywood/ osb and expect the ceramic tile and grout to last? 100% better to use cement board or that synthetic strand board?

- OK I have to set the record straight here. So I hope I don t step on any toes.. 1/2 inch ply ( not osb) is a substrate you can use on flooring to use for tile. Must be well glued and nailed or screwed down. 6 inches or less on all seams and a minimum or 8 inches in the field. 1/8 to 1/4 inch expansion joints on the seams. No bigger no smaller. All seams must be taped w/ proper tape and thin set. I will agree that cement board is a great flooring substrate for tile but it is cheaper to use wood. This ply should be a 3 ply plywood not the common 5 ply. I ve used this method for 20 years and always used ATC codes . The use of proper thin set is a must also as a few others have stated.. Any questions you can e mail me. GL

- Q:We recently hired a contractor to remodel the entire bathroom due to water damage. We are getting close to tiling. There is a tub going in then the walls will be tiled for the shower.The contractor put green board in the entire bathroom first. Then he put water barrier paper over the green board in the areas that will be tiled. Then put hardy backer cement board over that. Is this a good way to do it? There is no cement board below a certain height because the tub will be there. I wasn't sure if this is a good way to do it?

- It's fine. I wouldn't have put the green board up where the cement board was going up, to save time an money. The green board is unnecessary there. But, it won't cause any problems.

- Q:Should the cement board be behind the tile flange?

- You should keep the cement board behind the tile flange.

- Q:A list of US suppliers is here w/ some discussion.

- Haven't experienced it but from what I read in your link, it gets hung/nailed like drywall and underlayment. If you're not familiar with how to hang drywall, the first link is a very informative step by step video. Second link, though not a video is how to install cement board/fiber underlayment. Hope this will be of help to you - good luck!

- Q:can plywood be used instead of cement backer- board for tile?

- Im not for certain but i don't think it can be used instead of cement backer board. Plywood is very preamble and the grout may soak through? I would call a Lowe's or Home Depot and ask for the flooring dept. or lumber and ask them.

- Q:How do I remove dried cement from door & running board?

- Adhesive remover. ADDED: Oh, do you mean concrete? Good luck. Chip it off...?

- Q:Do I have to put cement backer board down before laying ceramic tile or can I go over existing vinyl floor?

- you need backer board because the initial cement that you lay the tile with will not stick to vinyl. The vinyl is unstable and will not take the grout either - years later you will have cracking heaving mess. Also you need a level area and vinyl tends to buckle and so forth.

- Q:What is the prc in the building?

- PRC (Pore Reduced Cement) is a high-performance cement material, it is in the process, performance, use, etc. have many unique advantages

- Q:Can cement board be tiled?

- Kitchen flue is made of cement board if the wall is not hard to use the red brick and then posted again

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiber Cement board for villas,high building-004

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords